Horizontal multi-stage separator

A separator and horizontal technology, which is applied in the field of horizontal multi-stage separators, can solve the problems of reducing the filtering effect, easy to damage the filter element, reducing the compressive strength and filtering efficiency, and achieve the effect of improving the filtering efficiency and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

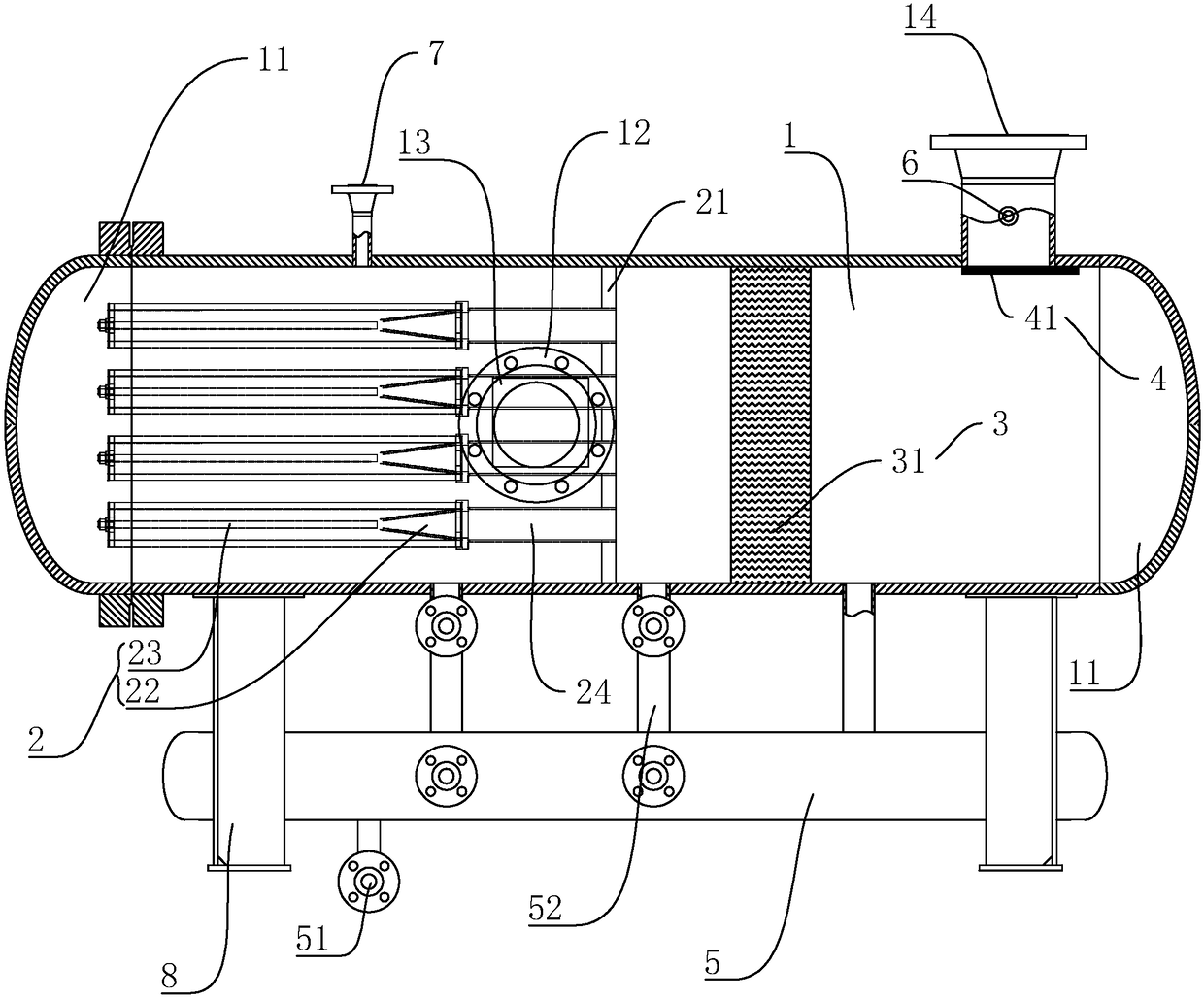

[0032] Embodiment 1, a kind of horizontal multistage separator, such as figure 1 As shown, it includes a cylinder body 1 which is cylindrical as a whole and arranged horizontally. Both ends of the cylinder body 1 are fixed with heads 11, and the heads 11 are arranged in a semi-elliptical shape. A saddle 8 is provided at the bottom of the cylinder body 1 to support the entire cylinder body 1. An inlet pipe 12 is arranged on the side wall in front of the cylinder body 1. An outlet pipe 14 is arranged on the side wall at the top of the cylinder body 1. Natural gas flows through the inlet pipe 12. Enter and exit through outlet pipe 14.

[0033] Such as figure 1 As shown, the cylinder 1 is provided with a primary filter unit 2, a secondary filter unit 3 and a tertiary filter unit 4 in sequence from the inlet pipe 12 to the outlet pipe 14, and the primary filter unit 2 and the secondary filter unit 3 pass through The mounting plate 21 is isolated. The primary filter unit 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com