A grid type electrocatalytic oxidation catalytic material and its preparation process

An electrocatalytic oxidation and catalytic material technology, which is applied in catalyst activation/preparation, heterogeneous catalyst chemical elements, oxidized water/sewage treatment, etc. It is not long enough to achieve the effect of improving water quality standards, optimizing treatment plans, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

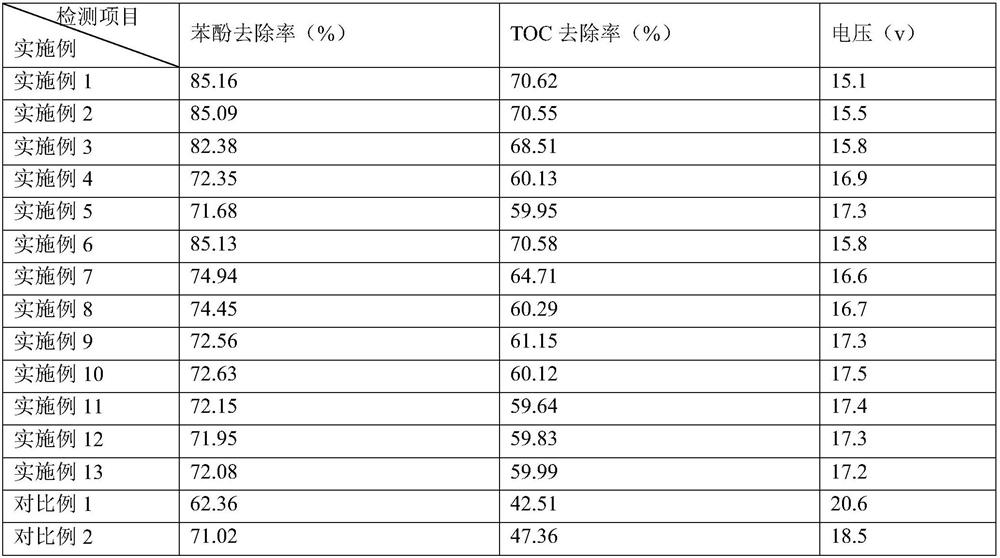

Examples

Embodiment 1

[0046] Embodiment 1: a grid type electrocatalytic oxidation catalytic material, prepared by the following steps:

[0047] S1, the clinoptilolite raw material is screened, washed, wet-milled, precipitated, air-dried, calcined in a muffle furnace at 400° C. for 2 hours, and cooled to obtain clinoptilolite powder;

[0048] S2, the clinoptilolite powder obtained in step S1 is fully immersed in a sodium chloride solution with a concentration of 1.0 mol / L, mechanically stirred for 5 hours in a water bath at 70°C, filtered and washed with pure water until no chloride ions are present Detected, placed in an oven and dried at a temperature of 108 ° C to obtain activated clinoptilolite powder;

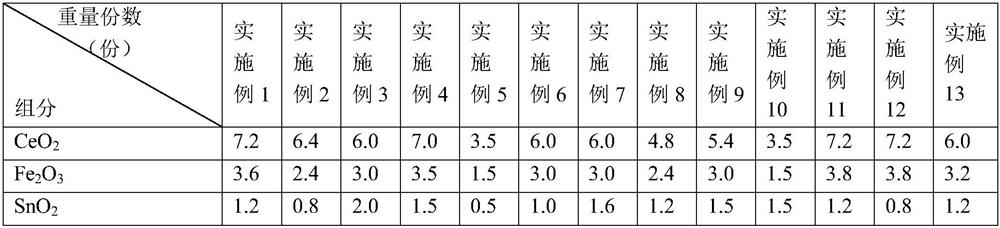

[0049] S3, the Ce (NO 3 ) 3 ·6H 2 O, 4.4-10.9 parts of FeCl 3 , 0.87-2.77 parts of SnC l4 , dissolved in 100mL of pure water, and mixed thoroughly to form an immersion solution;

[0050] S4, take 100 parts of the activated clinoptilolite powder obtained in step S2 and add it to the immersi...

Embodiment 2

[0052] Example 2: A grid-type electrocatalytic oxidation catalytic material, the difference from Example 1 is that, in step S1, the clinoptilolite raw material is calcined in a muffle furnace at a temperature of 300°C and a calcination time of 3h.

Embodiment 3

[0053] Example 3: A grid-type electrocatalytic oxidation catalytic material, the difference from Example 1 is that in step S1, the temperature of calcining the clinoptilolite raw material in a muffle furnace is 100°C, and the calcining time is 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com