Condenser combined mechanism

A combined mechanism and condenser technology, used in equipment for feeding molten metal into molds, pig iron foundries, manufacturing tools, etc., can solve problems such as low productivity, large difference in composition, and composition segregation, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

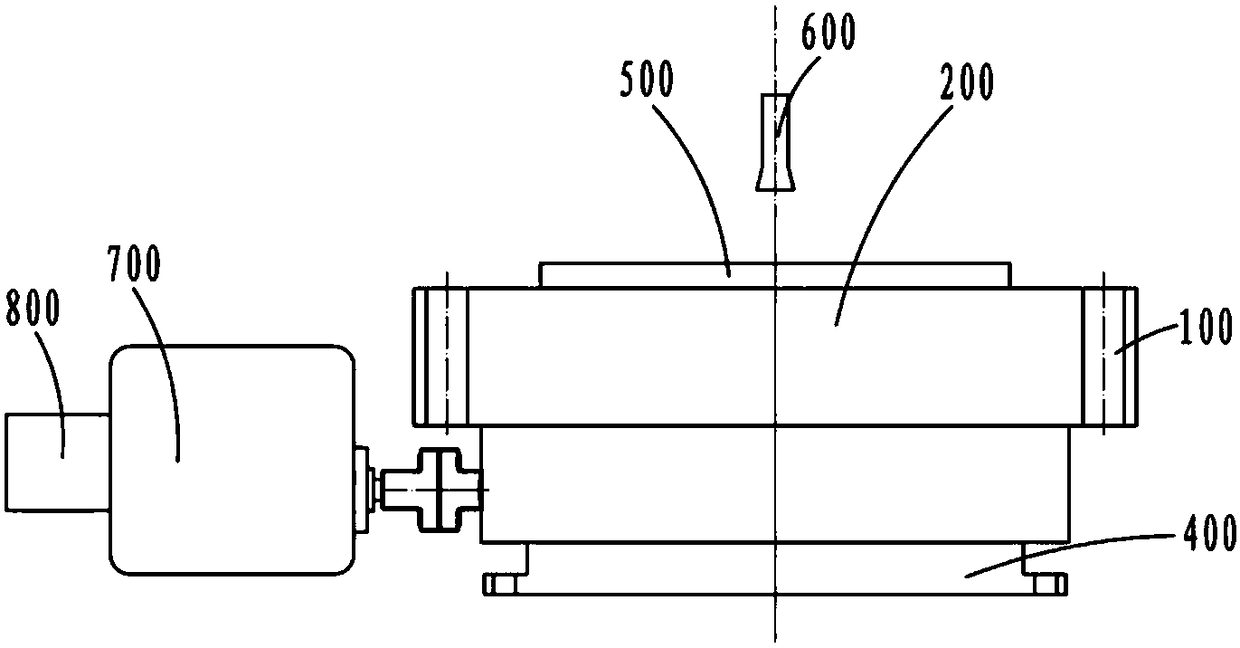

[0026] see figure 1 and figure 2 , In a preferred embodiment of the present invention, a rotary casting equipment includes a condenser combination mechanism 100 , a rotary platform 200 , a bracket 400 , a water distributor 500 , a liquid level measuring and controlling instrument 600 , a driver 700 and an electrical system 800 .

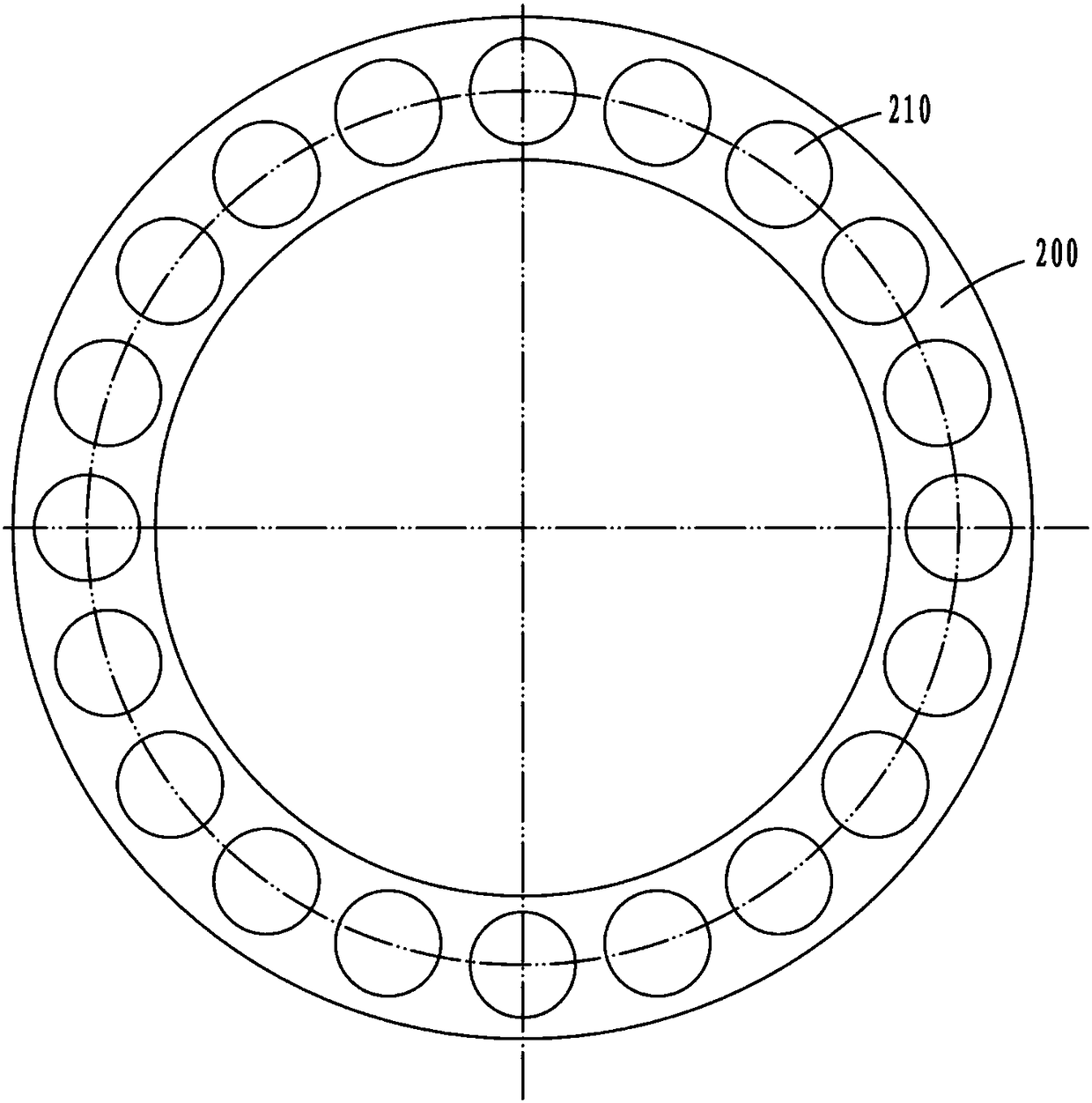

[0027] The slewing platform 200 is installed on the bracket 400, and the slewing platform 200 is provided with several mounting holes 210. The slewing platform 200 is made of metal material, such as steel or stainless steel or cast iron or other engineering materials. The electrical system 800 is electrically connected with the driver 700 to control the rotation of the rotary platform. The drive shaft of the driver 700 is connected to the rotary platform 200 to drive the rotary platform 200 to perform horizontal intermittent rotary motion around the center.

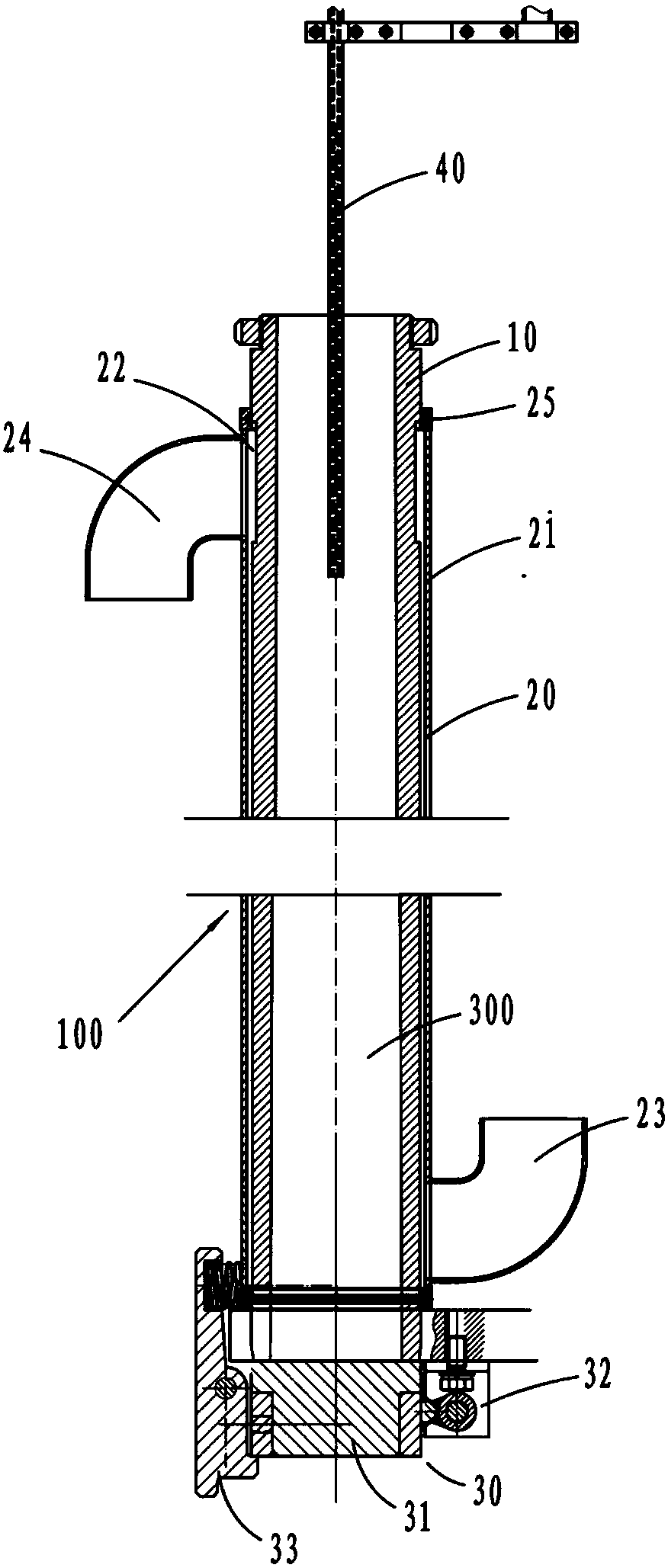

[0028] The plurality of condenser assembly mechanisms 100 are respectively installed vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com