Reverse osmosis system capable of increasing seawater desalination recovery rate and recovery method

A desalination system and reverse osmosis technology, applied in the field of seawater desalination, can solve the problems of high operating cost, low recovery rate, large energy consumption per ton of water, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

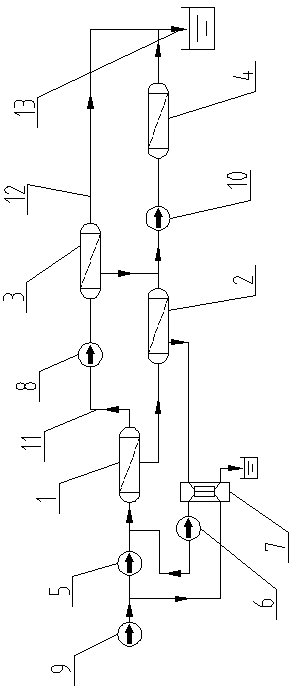

[0023] A reverse osmosis system for improving the recovery rate of seawater desalination, comprising: a primary desalination system 11 and a secondary desalination system 12, the primary desalination system comprising a primary reverse osmosis membrane front end 1 and a primary reverse osmosis membrane rear End 2, the concentrated water outlet at the front end of the primary reverse osmosis membrane is connected to the seawater inlet at the rear end of the primary reverse osmosis membrane through a high-pressure pipeline;

[0024] The two-stage desalination system includes two-stage reverse osmosis membrane A, part number: 3 and two-stage reverse osmosis membrane B, part number: 4, the seawater inlet of the two-stage reverse osmosis membrane A is the same as the first-stage The fresh water outlet at the front end of the reverse osmosis membrane is connected through a secondary high-pressure pump A, part number: 8, and the seawater inlet of the secondary reverse osmosis membrane...

Embodiment 2

[0026] According to the reverse osmosis system for improving the recovery rate of seawater desalination described in Example 1, the fresh water outlet of the secondary reverse osmosis membrane A and the outlet of the secondary reverse osmosis membrane B are respectively connected to the total water outlet 13 through the pipeline connect.

Embodiment 3

[0028] According to the reverse osmosis system for improving the recovery rate of seawater desalination described in embodiment 1 or 2, the concentrated water outlet at the rear end of the primary reverse osmosis membrane is connected to the concentrated water inlet of the energy recovery device 7 through a pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com