Antibacterial offset printing ink and preparation method thereof

An offset printing ink and antibacterial technology, applied in the field of antibacterial offset printing ink and its preparation, can solve the problems of single antibacterial performance, poor reproducibility of antibacterial effect, insignificant effect, etc. Ability, lasting and stable antibacterial effect, good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

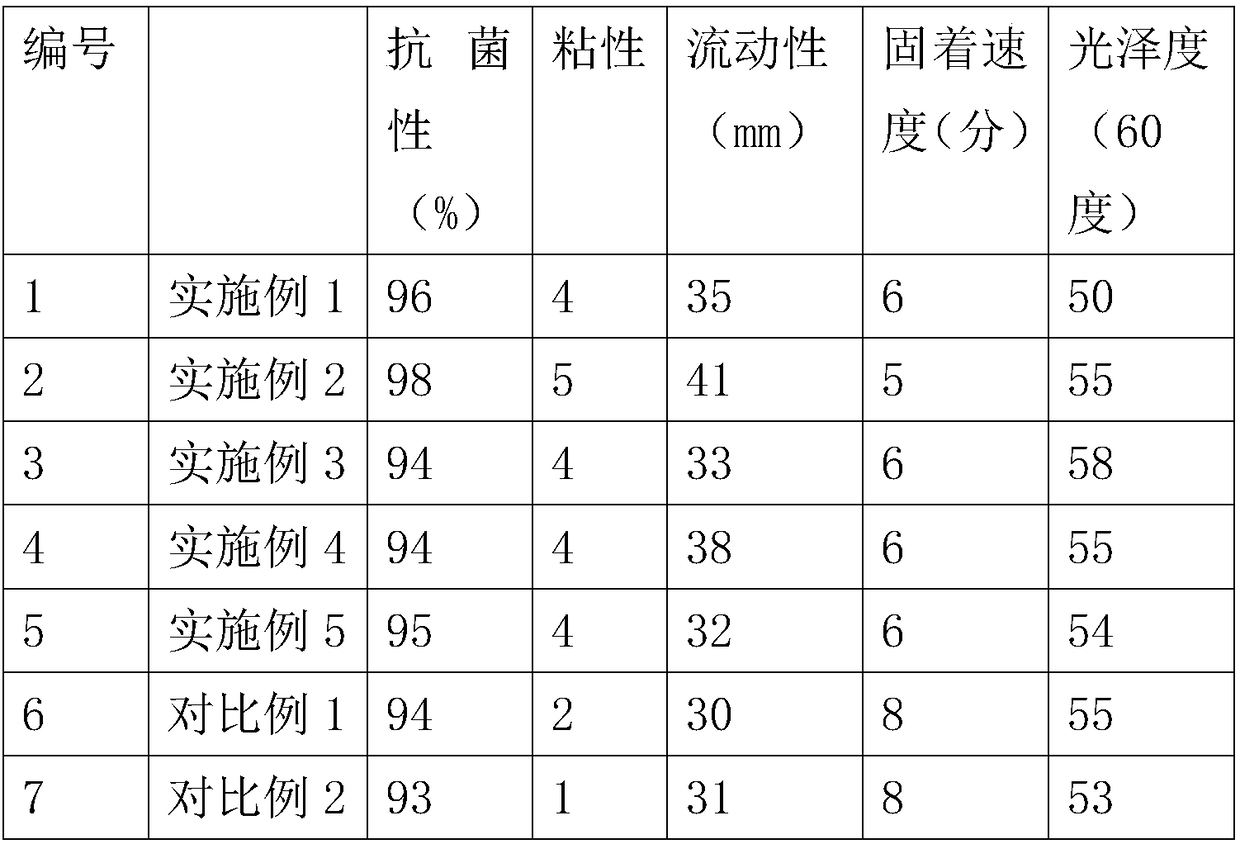

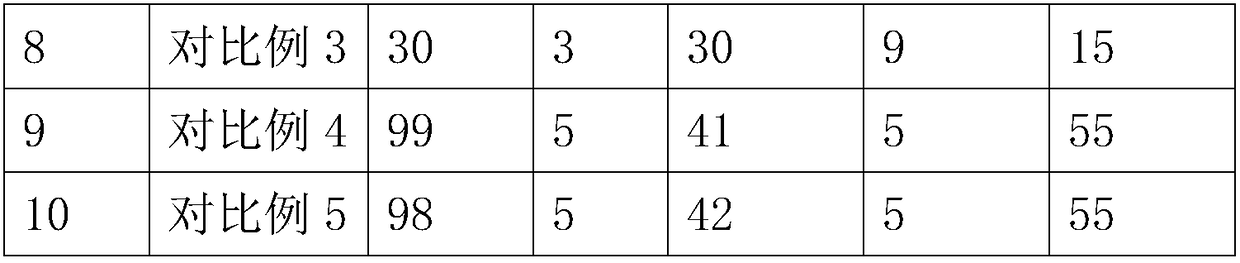

Examples

Embodiment 1

[0028] An antibacterial offset printing ink comprises 60kg of binder, 4kg of pigment, 30kg of filler, 30kg of solvent, and 1kg of bactericide, and the particle diameter of the titanium dioxide is 23nm.

Embodiment 2

[0030] An antibacterial offset printing ink comprises 70kg of binder, 5kg of pigment, 35kg of filler, 35kg of solvent, and 2kg of bactericide, and the particle diameter of the titanium dioxide is 23nm.

Embodiment 3

[0032]An antibacterial offset printing ink comprises 80kg of binder, 6kg of pigment, 40kg of filler, 40kg of solvent, and 3kg of bactericide, and the particle diameter of the titanium dioxide is 23nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com