Methods for increasing clarity and refreshing attributes and reducing bitterness and astringency of green tea

A technology of green tea and bitterness, which is applied in the direction of tea, tea extraction, tea alkali content reduction, etc., which can solve the problems of narrow threshold of astringency and bitterness, sensitivity, etc., and achieve the effect of low bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0088] The present invention provides methods for increasing the clarity and modulating the bitterness, astringency and lingering of green tea and nutritional products containing green tea to reduce the bitterness, astringency and lingering. Green tea produced according to the methods described herein has lower bitterness, astringency and lingering taste compared to conventional green tea, but still retains higher antioxidants (such as flavonoids or flavan-3-ols or catechins) quantity.

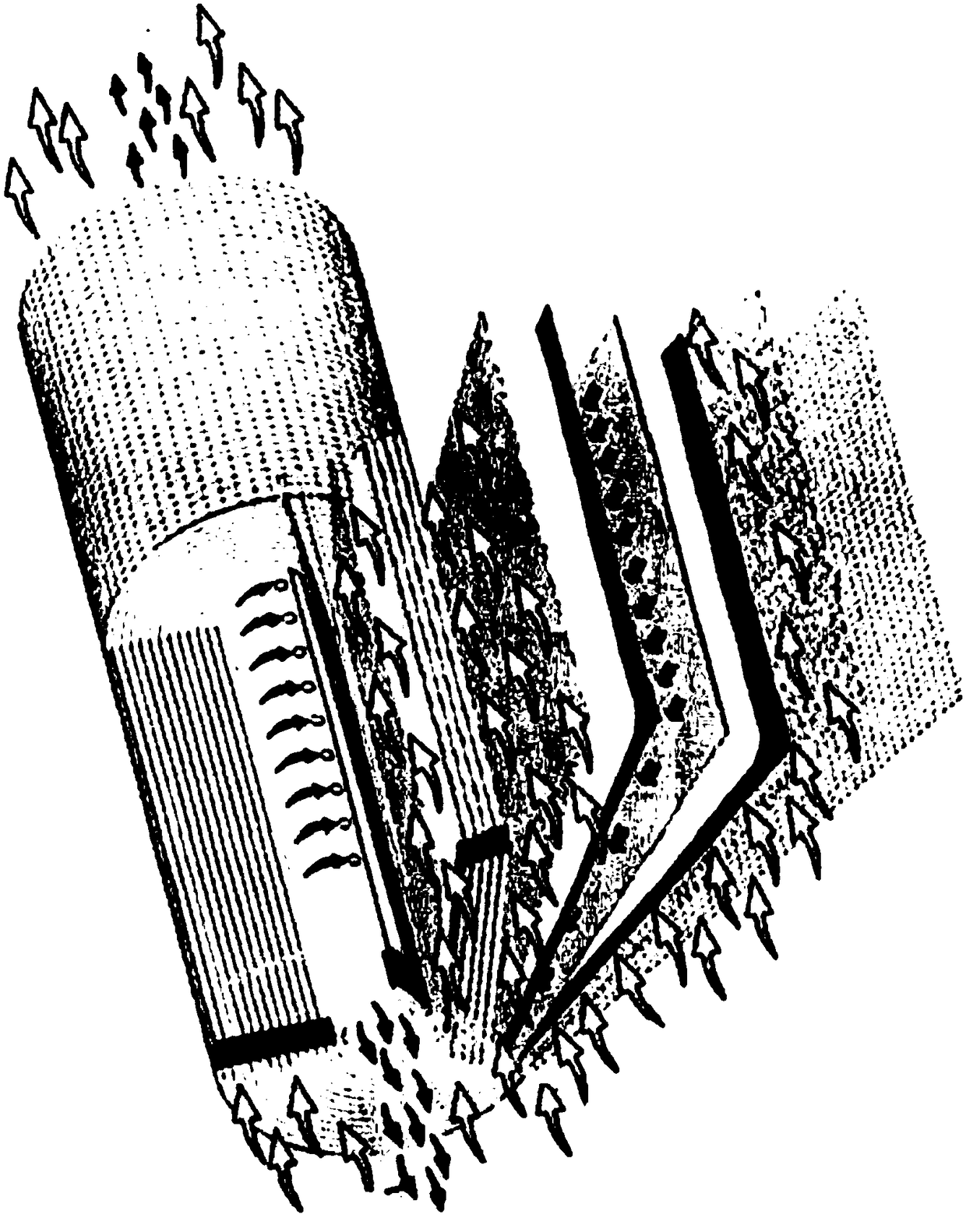

[0089] In general embodiments, the present invention provides a method for improving the clarity of green tea products; reducing the bitterness, astringency, and persistence of green tea products; and enhancing the freshness attributes of green tea products. The method involves microfiltration of the green tea extract. The microfiltration membrane preferably has a pore size of about 0.1 μm. Another physical technique such as centrifugation can also be used instead of microfiltration. Howeve...

Embodiment

[0132] The following examples illustrate various embodiments of the present disclosure by way of illustration and not limitation.

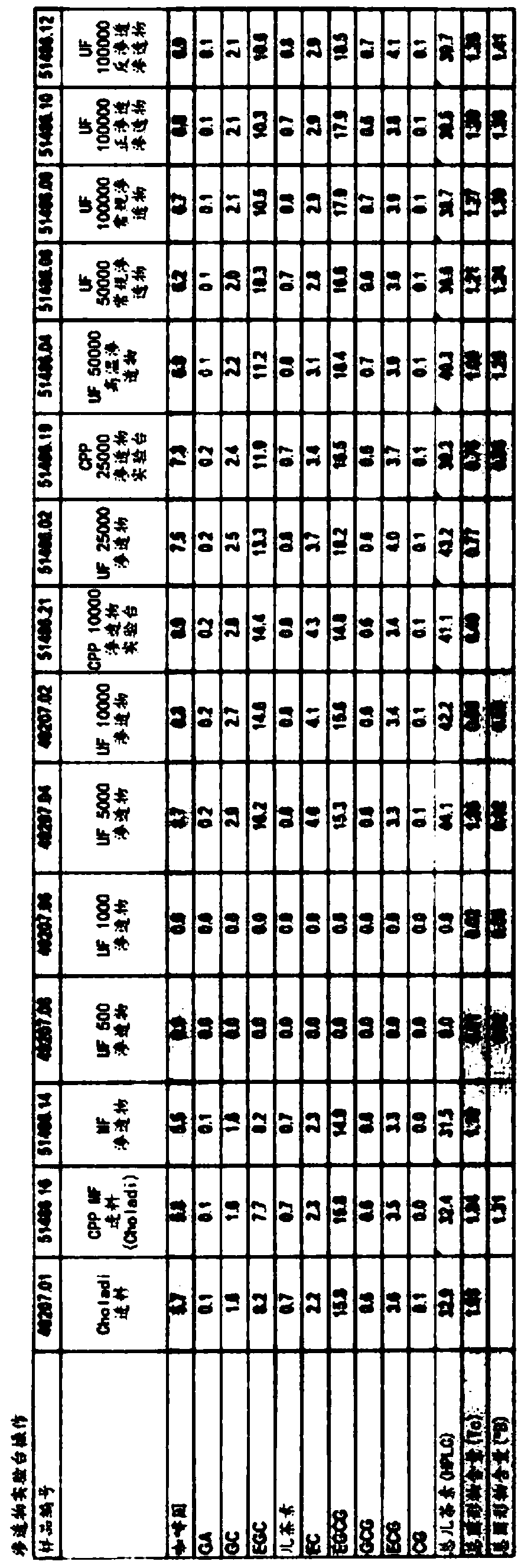

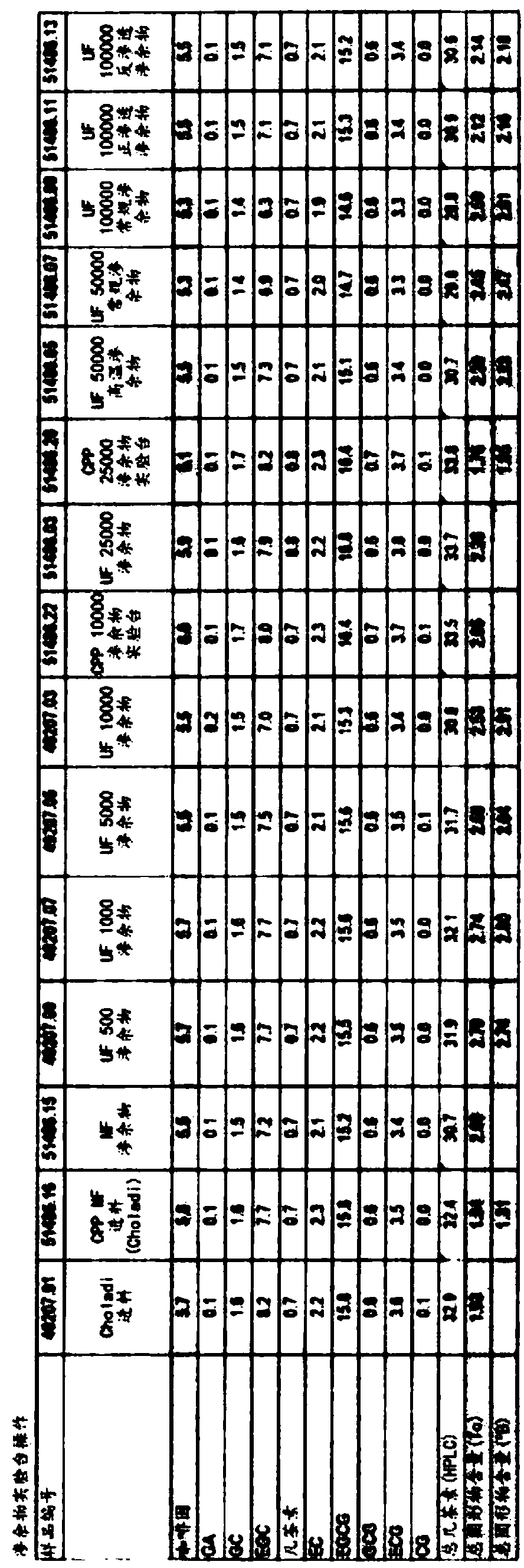

[0133] The studies in these examples were conducted in three phases: (1) bench-top membrane screening using flat sheet membranes with different molecular weight cut-offs (MWCO); (2) joint pilot plant or mid-scale laboratory ( CPP) Microfiltration (MF) and Ultrafiltration (UF); (3) Experimental Benchtop Study of Low Temperature Fractionation (RTF) at Freezing (-20°C) and Refrigerated (4°C and 8°C) Temperatures.

[0134] The objectives of the study were as follows: (1) To determine whether microfiltration and / or MWCO membranes could fractionate high polyphenol content green tea by targeting removal of larger molecular weight (MW) molecules such as those identified as astringents in the literature flavonol glycosides) to obtain fractions with lower bitterness and astringency; (2) to identify other potential product advantages such as high clarity, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com