Novel cement foaming machine

A new type of cement foaming technology, applied in cement mixing devices, mixing plants, sales of raw material supply devices, etc., can solve problems such as difficult control of water-cement ratio, impact on project quality, and project rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

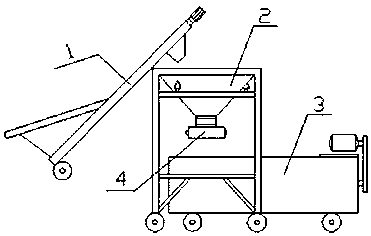

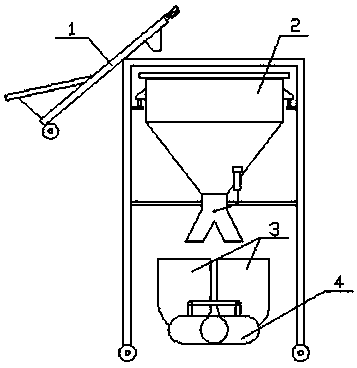

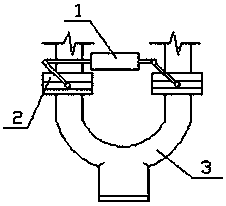

[0025] The new cement foaming machine is mainly improved in three aspects: the feeding system, the foaming system and the mixing machine of the old cement foaming machine.

[0026] The mixing ratio control in the production process of cast-in-place foam concrete is a key link. After investigation, most of the current cement foaming machine feeding systems in the market are direct feeding of belt conveyors, direct feeding of screw conveyors and direct feeding of collection hoppers. Three forms. The direct feeding of the belt conveyor cannot be accurately measured, and the dust pollution is also large. It is recommended to eliminate it. The screw conveyor is more suitable for feeding, but it is necessary to add a metering control system. The simple method is to use a frequency converter to control the motor speed to achieve simple metering. However, this kind of metering is still very rough. It is best to use a screw conveyor with metering function or additional metering Bucket-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com