Preparation method of graphene-nano-zinc hydrogel electrode

A nano-zinc, hydrogel technology, applied in the field of electrochemistry, can solve problems such as unsatisfactory conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

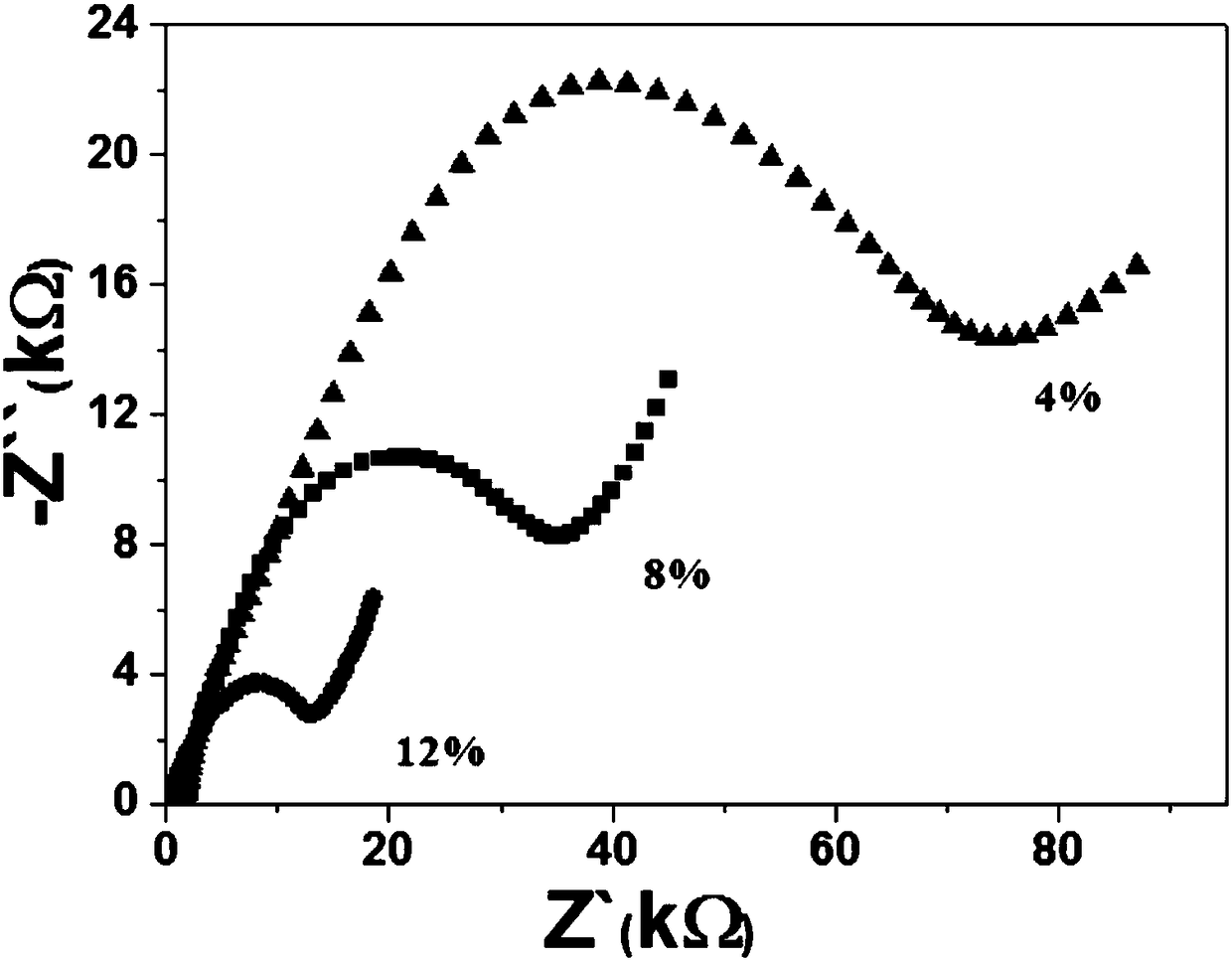

Image

Examples

preparation example Construction

[0031] A preparation method of graphene-nanometer zinc hydrogel electrode, comprising the following steps:

[0032] Graphene oxide solution, ZnSO 4 ·7H 2 O solution and vitamin C solution are mixed and reacted to obtain a graphene-nanometer zinc hydrogel electrode;

[0033] The concentration of the vitamin C solution is 3-6 μmol / L;

[0034] The ZnSO 4 ·7H 2 The concentration of O solution is 4-6 mg / mL;

[0035] The graphene oxide solution, ZnSO 4 ·7H 2 The volume ratio of the O solution and the vitamin C solution is (3-7): (0.1-0.3): (0.2-0.6).

[0036] In the present invention, graphene oxide solution is prepared according to the following steps:

[0037] A) graphite powder and sodium nitrate are mixed with concentrated sulfuric acid under ice bath conditions to obtain a mixed solution;

[0038] B) Potassium permanganate is added successively to the mixed solution for reaction, then deionized water is added successively to continue the reaction, pure water is added t...

Embodiment 1

[0056] Mix 2g of natural graphite powder and 1g of sodium nitrate with 45mL of concentrated sulfuric acid in an ice bath;

[0057] Slowly add 5g of potassium permanganate to the above materials one by one, keep the temperature of the materials below 20°C and stir for 2h, then continue to react at 35°C for 30min, then slowly add 90mL of deionized water to the materials one by one, and raise the temperature to Continue to react at 95°C for 3 h, add pure water to terminate the reaction, and add 5 mL of 30% H at the same time 2 o 2 , cooled to room temperature;

[0058] The resulting material is subjected to suction filtration to obtain a filter cake;

[0059] Wash the above filter cake with hydrochloric acid aqueous solution and pure water successively to remove residual metal ions and hydrochloric acid, then redisperse the washed filter cake in water, and centrifuge at 2000rpm for 10min to remove unoxidized graphite to obtain a clear liquid;

[0060] Sonicate the supernatant ...

Embodiment 2

[0066] The graphene-nanometer zinc hydrogel electrode was prepared according to the method in Example 1, except that the volume fractions of graphene oxide solution and vitamin C were 88% and 8%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com