Circulating water softening system based on variable frequency pulse electric field and its realization method

A technology of frequency conversion pulse and circulating water, applied in the field of softened water system, can solve the problems of pollution, high production cost, large consumption, etc., and achieve the effect of zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

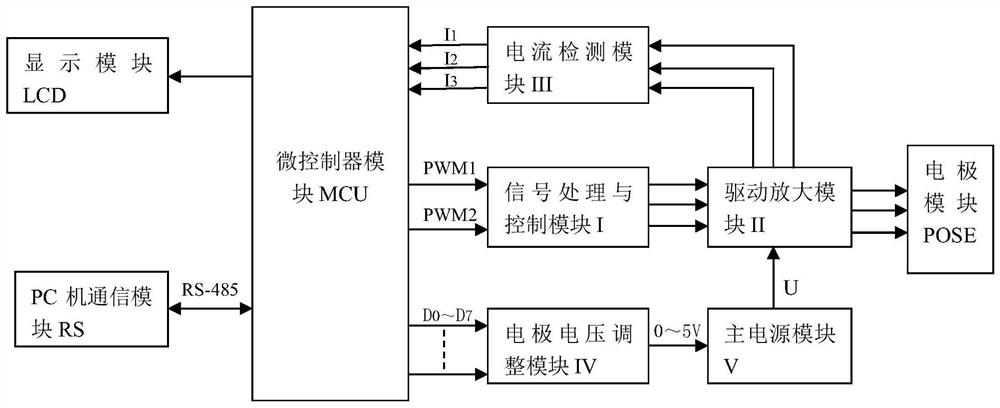

[0044] Such as Figure 1-10 As shown, the circulating water softening system based on variable frequency pulse electric field provided by the present invention includes a control box, an electrode module POSE placed in a circulating water storage tank, and a PC communication module RS.

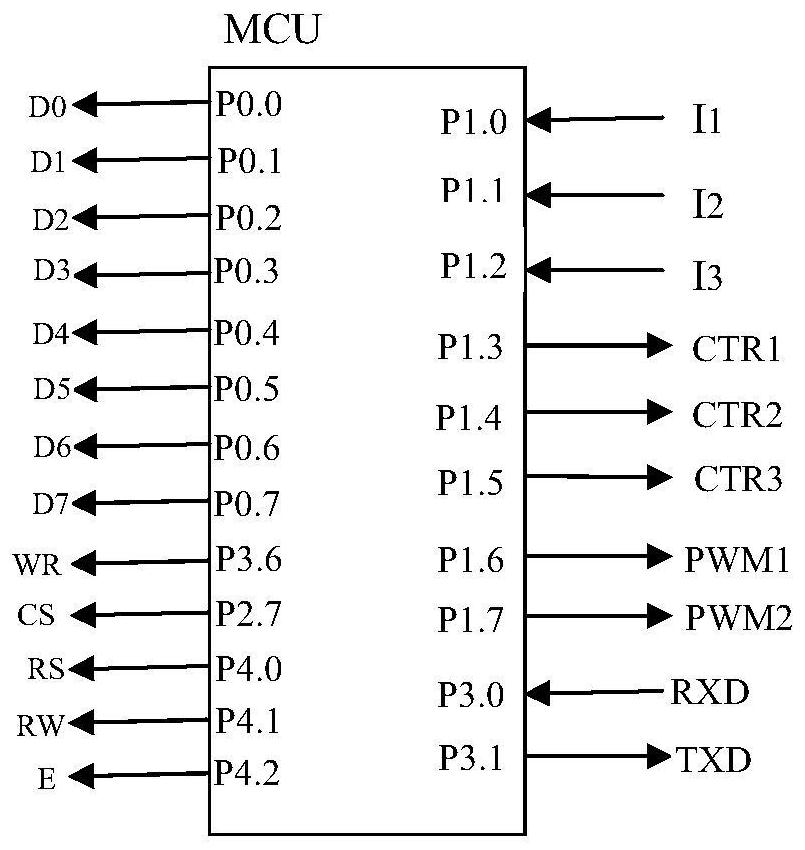

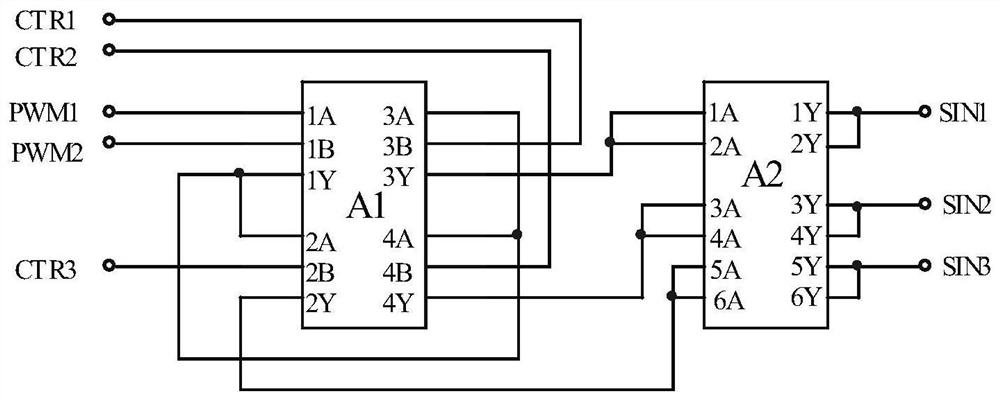

[0045] The inside of the control box is provided with a microcontroller module MCU, a signal processing and control module I, a drive amplification module II, a current detection module III, a main power supply module V, and an electrode voltage adjustment module IV. Set on the display module LCD, the display module LCD is connected to the microcontroller module MCU through a cable, the electrode module POSE is connected to the drive amplifier module II through a cable, and the PC communication module RS includes a The internal TTL / RS485 converter and the RS485 / RS232 converter installed on the PC end, the microcontroller module MCU sends PWM signals to the drive amplifier module II through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com