Catalytic ceramic membrane reactor

A catalytic ceramic membrane and reactor technology, which is applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc., can solve the problems of membrane fouling cleaning cost, etc., and achieve increased pollution resistance and high removal efficiency , the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

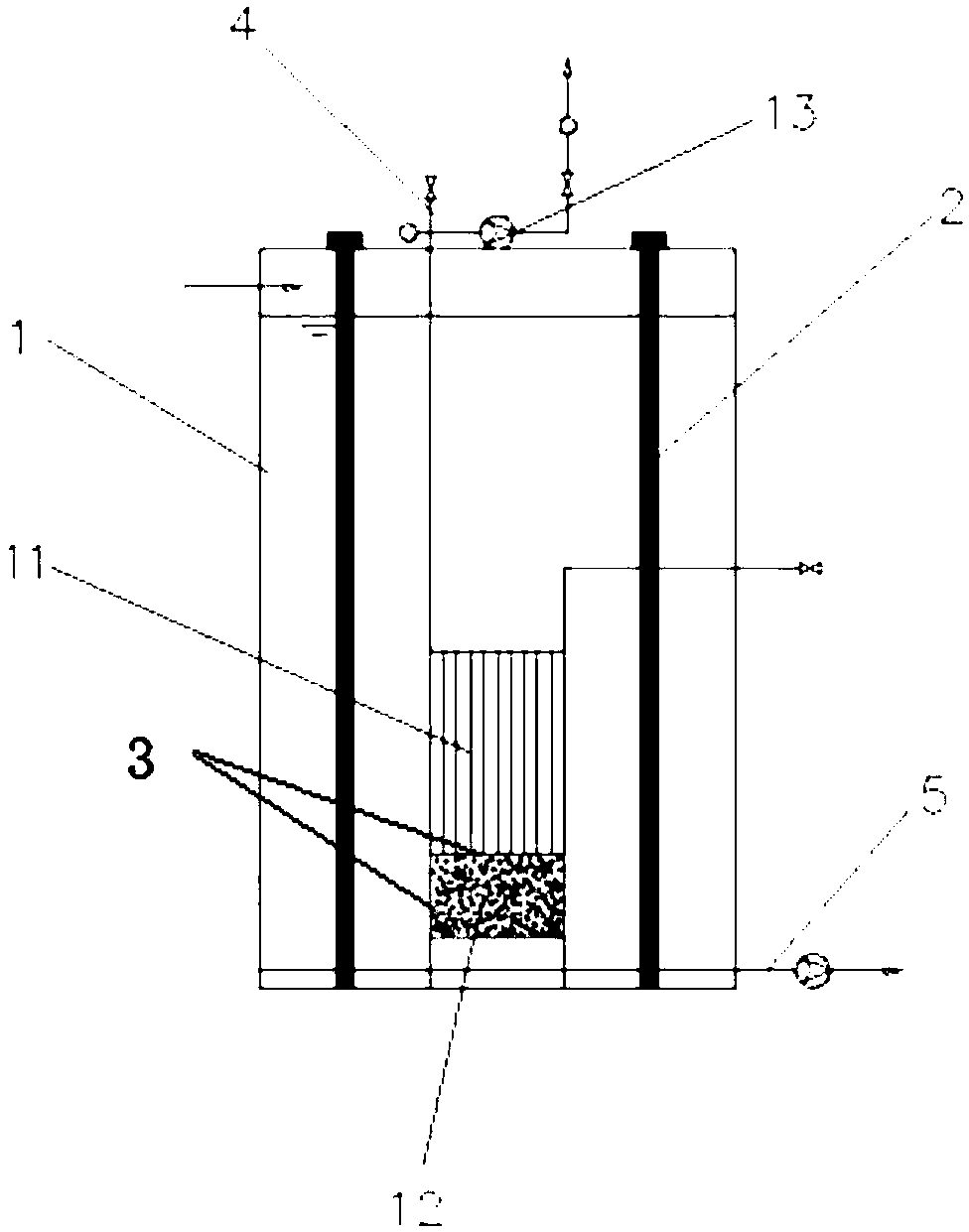

[0044] like figure 1 As shown, this embodiment provides a catalytic ceramic membrane reactor, including a reactor 1, and the reactor 1 is provided with a catalytic ceramic membrane module 11, a catalytic energy supply system 2, an aeration system, and a catalyst recovery system 5; The catalytic ceramic membrane module 11 is arranged in the middle of the reactor 1; the catalytic energy supply system 2 is arranged outside the catalytic ceramic membrane module 11; the bottom of the nano ceramic membrane module 11 is provided with an aeration system and a catalyst recovery system in sequence 5; The reactor 1 is filled with a photocatalyst-containing sol system.

[0045]In the photocatalyst-containing sol system, the photocatalyst includes nano-titanium dioxide P25 and a composite catalyst; the average particle diameter of the nano-titanium dioxide P25 is 25 nanometers, and forms 600-800nm sol particles after contacting with water;

[0046] The concentration of the nano-titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com