Aerogel-foamed rubber composite particles for sewage treatment and preparation method thereof

A foamed rubber and composite particle technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems that the adsorption technology cannot perform thorough adsorption and cannot thoroughly clean the water surface, etc. Achieve the effect of overcoming difficult to clean water surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

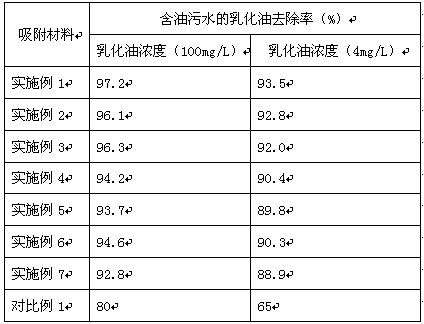

Examples

Embodiment 1

[0044] Preparation method of airgel-foamed rubber composite particles for sewage treatment:

[0045] (1) Preparation of silica sol: Mix ethyl orthosilicate, absolute ethanol and water at a volume ratio of 15:22.5:6.5, stir for 125 minutes, adjust the pH to 5, and continue stirring for 16.5 hours to form silica Sol;

[0046] (2) Preparation of composite gel: Mix the silica sol prepared in step (1) with octylphenol polyoxyethylene ether, stir at room temperature for 22 hours, adjust the pH value to 5.5, raise the temperature to 45.5°C, and let stand After 24 hours, add acetone and leave it to stand for 21 hours to obtain a composite gel; wherein, the weight ratio of silica sol, octylphenol polyoxyethylene ether and acetone is 100:8:40;

[0047] (3) Preparation of airgel-foamed rubber composite particles: Mix nitrile foamed rubber particles and composite gel at a ratio of 40:1 by weight, stir at room temperature for 7.4 hours, then stir at 72°C for 8.5 hours, take out Granules ...

Embodiment 2

[0049] Preparation method of airgel-foamed rubber composite particles for sewage treatment:

[0050] (1) Preparation of silica sol: Mix ethyl orthosilicate, absolute ethanol and water at a volume ratio of 15:22:6, stir for 120 minutes, adjust the pH value to 4.5, and continue stirring for 16 hours to form silica Sol;

[0051] (2) Preparation of composite gel: Mix the silica sol prepared in step (1) with octylphenol polyoxyethylene ether, stir at room temperature for 21 hours, adjust the pH value to 5.5, raise the temperature to 45°C, and let stand After 24 hours, add acetone and leave it to stand for 20 hours to obtain a composite gel; wherein, the weight ratio of silica sol, octylphenol polyoxyethylene ether and acetone is 100:7:35;

[0052] (3) Preparation of airgel-foamed rubber composite particles: mix nitrile foamed rubber particles and composite gel at a weight ratio of 45:1, stir at room temperature for 7.2 hours, then stir at 68°C for 8 hours, take out Granules were ...

Embodiment 3

[0054] Preparation method of airgel-foamed rubber composite particles for sewage treatment:

[0055] (1) Preparation of silica sol: Mix ethyl orthosilicate, absolute ethanol and water at a volume ratio of 15:23:7, stir for 130 minutes, adjust the pH value to 5.5, and continue stirring for 17 hours to form silica Sol;

[0056] (2) Preparation of composite gel: Mix the silica sol prepared in step (1) with octylphenol polyoxyethylene ether, stir at room temperature for 23 hours, adjust the pH to 5.5, raise the temperature to 46°C, and let stand 24 hours, add acetone again, stand still for 22 hours, make composite gel; Wherein, the weight ratio of silica sol, octylphenol polyoxyethylene ether and acetone is 100:9:45;

[0057] (3) Preparation of airgel-foamed rubber composite particles: Mix the nitrile foamed rubber particles and the composite gel at a weight ratio of 35:1, stir at room temperature for 7.5 hours, then stir at 75°C for 9 hours, take out Granules were dried in a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com