Processing method of high barrier bacteriostatic starch-based composite material

A composite material and processing method technology, applied in the processing field of high-barrier antibacterial starch-based composite materials, can solve the gap between product performance, manufacturing cost, key technology and industrial scale, few high-barrier and antibacterial dual-functional materials, and cannot Form high barrier and antibacterial materials and other problems, achieve the effect of promising market prospects, low cost, and solving oil crisis and plastic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Prepare high-barrier antibacterial starch-based composite materials as follows:

[0066] (1) Prepare ordinary starch into a starch milk solution with a concentration of 5%, heat it for complete gelatinization, cool to 35°C, adjust the pH to 3.5, and add isoamylase (0.5U / g starch) for 3 hours;

[0067] (2) Add 1% antibacterial agent after the enzyme-inactivating treatment and stir at 4°C for 5 minutes, then dry and pulverize to obtain the starch compound;

[0068] (3) Mix the starch compound, polysaccharide nanocrystals, and compatible chain extender according to the mass percentage of 100:1:0.5, and dry reaction at 80°C, 70r / min, 0.1MPa for 5min, after the reaction is complete That is, a high-barrier antibacterial starch-based composite material is obtained.

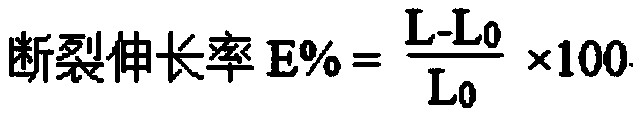

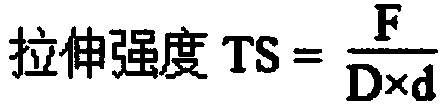

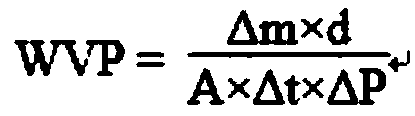

[0069] The starch-based composite material prepared in this example has a tensile strength of 7.35MPa, an elongation at break of 45%, and a water vapor transmission rate of 0.387g mm / m 2 ·h·kPa, the oxygen trans...

Embodiment 2

[0071] Prepare high-barrier antibacterial starch-based composite materials as follows:

[0072] (1) Prepare ordinary starch into a starch milk solution with a concentration of 30%, heat it for complete gelatinization, cool to 55°C, adjust the pH to 6.0, and add pullulanase (10U / g starch) for 10 hours;

[0073] (2) Add 5% antibacterial agent after the enzyme-inactivating treatment and stir at 20°C for 10 minutes, then dry and pulverize to obtain the starch compound;

[0074] (3) Mix the starch compound, polysaccharide nanocrystals, and compatible chain extender according to the mass percentage of 100:10:3, and dry-react at 120°C, 150r / min, and 10MPa for 30min. After the reaction is complete, the A high-barrier antibacterial starch-based composite material was obtained.

[0075] The starch-based composite material prepared in this example has a tensile strength of 10.10 MPa, an elongation at break of 70%, and a water vapor transmission rate of 0.248 g mm / m 2 ·h·kPa, the oxygen...

Embodiment 3

[0077] Prepare high-barrier antibacterial starch-based composite materials as follows:

[0078] (1) Prepare ordinary starch into a starch milk solution with a concentration of 15%, heat it for complete gelatinization, cool to 40°C, adjust the pH to 4.5, and add isoamylase (5U / g starch) for 6 hours;

[0079] (2) Add 3% antibacterial agent after the enzyme-inactivating treatment and stir at 10°C for 10 minutes, then dry and pulverize to obtain the starch compound;

[0080] (3) Mix the starch compound, polysaccharide nanocrystals, and compatible chain extender according to the mass percentage of 100:5:1, and dry-react at 100°C, 100r / min, and 5MPa for 15min. After the reaction is complete, the A high-barrier antibacterial starch-based composite material was obtained.

[0081] The starch-based composite material prepared in this example has a tensile strength of 9.32MPa, an elongation at break of 48%, and a water vapor transmission rate of 0.307g mm / m 2 ·h·kPa, the oxygen transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com