PE thin film packaging material and preparation method thereof

A technology of film packaging and raw materials, applied in the field of PE film packaging materials and its preparation, to achieve the effect of improving tensile strength and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

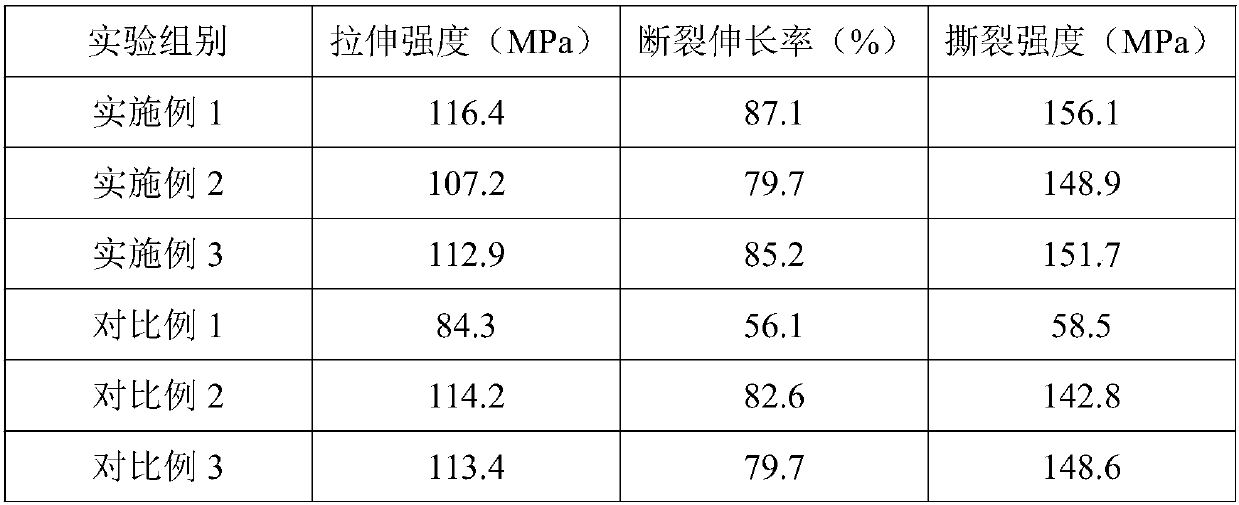

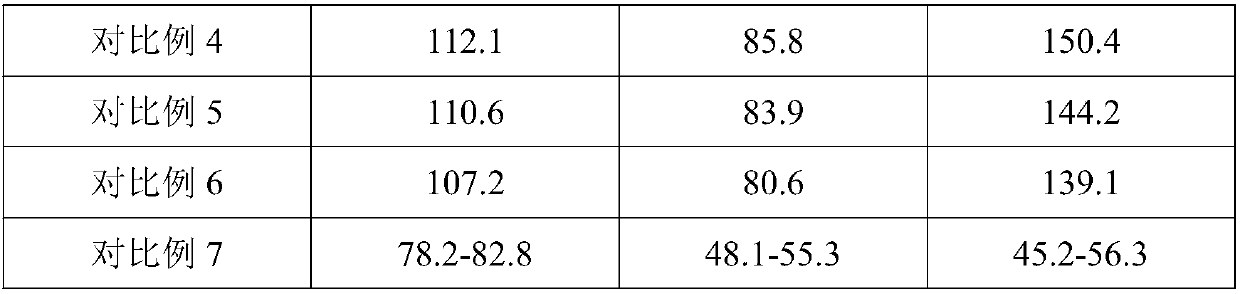

Examples

Embodiment 1

[0027] A PE film packaging material, in parts by weight, comprising the following raw materials: 92 parts of PE resin, nano-Si0 2 7 parts, 5 parts of sodium dodecylbenzenesulfonate, 11 parts of a-cyanoacrylate, 7 parts of aluminum isopropoxide, 8 parts of potassium methyl siliconate, 36 parts of polyethylene oxide, zinc stearate 30 parts, 17 parts of glycerin, 12 parts of montmorillonite, 13 parts of oleic acid, 7 parts of polyacetimide;

[0028] The preparation method of described PE film packaging material, comprises the following steps:

[0029] S1: by weight PE resin and nano-Si0 2 Put it in a three-head grinder and grind for 1.6h to make a nanocomposite material, then add sodium dodecylbenzenesulfonate, a-cyanoacrylate, aluminum isopropoxide, and potassium methyl siliconate in parts by weight and mix evenly. Melt at 172°C and react for 2 hours under a vacuum of 0.93 MPa to obtain a polymer solution;

[0030] S2: Dry the montmorillonite at 132°C for 1.5 hours, add it to...

Embodiment 2

[0034] A PE film packaging material, in parts by weight, comprising the following raw materials: 85 parts of PE resin, nano-Si0 2 5 parts, 4 parts of sodium dodecylbenzenesulfonate, 12 parts of a-cyanoacrylate, 8 parts of aluminum isopropoxide, 6 parts of potassium methyl siliconate, 32 parts of polyethylene oxide, zinc stearate 32 parts, 18 parts of glycerin, 9 parts of montmorillonite, 14 parts of oleic acid, 5 parts of polyacetimide;

[0035] The preparation method of described PE film packaging material, comprises the following steps:

[0036] S1: by weight PE resin and nano-Si02 Put it in a three-head grinder and grind for 1 hour to prepare a nanocomposite material, then add sodium dodecylbenzenesulfonate, a-cyanoacrylate, aluminum isopropoxide, and potassium methyl siliconate in parts by weight and mix evenly, and then Melt at 165°C and react for 2.5 hours under a vacuum of 0.9MPa to obtain a polymer solution;

[0037] S2: Dry the montmorillonite at 125°C for 2 hours, ...

Embodiment 3

[0041] A PE film packaging material, in parts by weight, comprising the following raw materials: 100 parts of PE resin, nano-Si0 2 8 parts, 6 parts of sodium dodecylbenzenesulfonate, 8 parts of a-cyanoacrylate, 4 parts of aluminum isopropoxide, 10 parts of potassium methyl siliconate, 40 parts of polyethylene oxide, zinc stearate 26 parts, 15 parts of glycerin, 13 parts of montmorillonite, 10 parts of oleic acid, 9 parts of polyacetimide;

[0042] The preparation method of described PE film packaging material, comprises the following steps:

[0043] S1: by weight PE resin and nano-Si0 2 Put it in a three-head grinder and grind for 2 hours to prepare a nanocomposite material, then add sodium dodecylbenzenesulfonate, a-cyanoacrylate, aluminum isopropoxide, and potassium methyl siliconate in parts by weight and mix evenly, and then Melt at 175°C and react for 1.5h under a vacuum of 0.95MPa to obtain a polymer solution;

[0044] S2: Dry the montmorillonite at 136°C for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com