Color-adjustable long-afterglow material and preparation method thereof

A long afterglow material and color technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of short afterglow time and energy loss, and achieve the effects of long afterglow time, high afterglow brightness and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of a long afterglow material with adjustable color, comprising the following steps:

[0044] A) grinding and mixing calcium-containing compounds, strontium-containing compounds, gallium-containing compounds, aluminum-containing compounds and manganese-containing compounds according to the stoichiometric ratio shown in formula I to obtain a mixture;

[0045] Ca x Sr 1-x Ga y Al 4-y o 7 :zMn 2+ Formula I;

[0046] Among them, 0≤x≤1, 0≤y≤4, 0

[0047] B) Calcining the mixture to obtain the long afterglow material with adjustable color shown in formula I.

[0048] In the present invention, the calcium-containing compound is preferably one or more of calcium carbonate, calcium nitrate and calcium oxalate; more preferably calcium carbonate;

[0049] The strontium-containing compound is preferably one or more of strontium carbonate, strontium nitrate and strontium oxalate; more preferably strontium carbo...

Embodiment 1

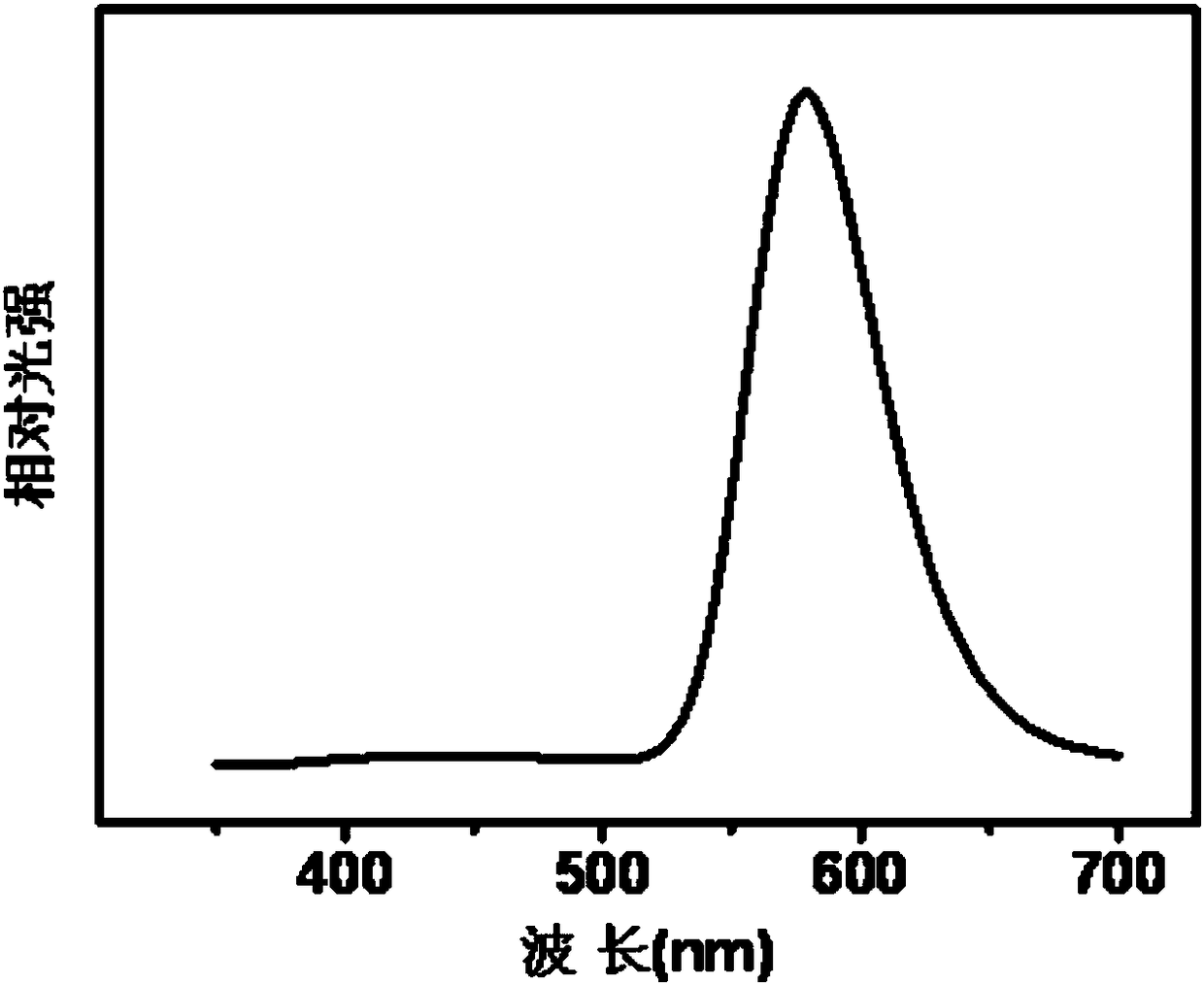

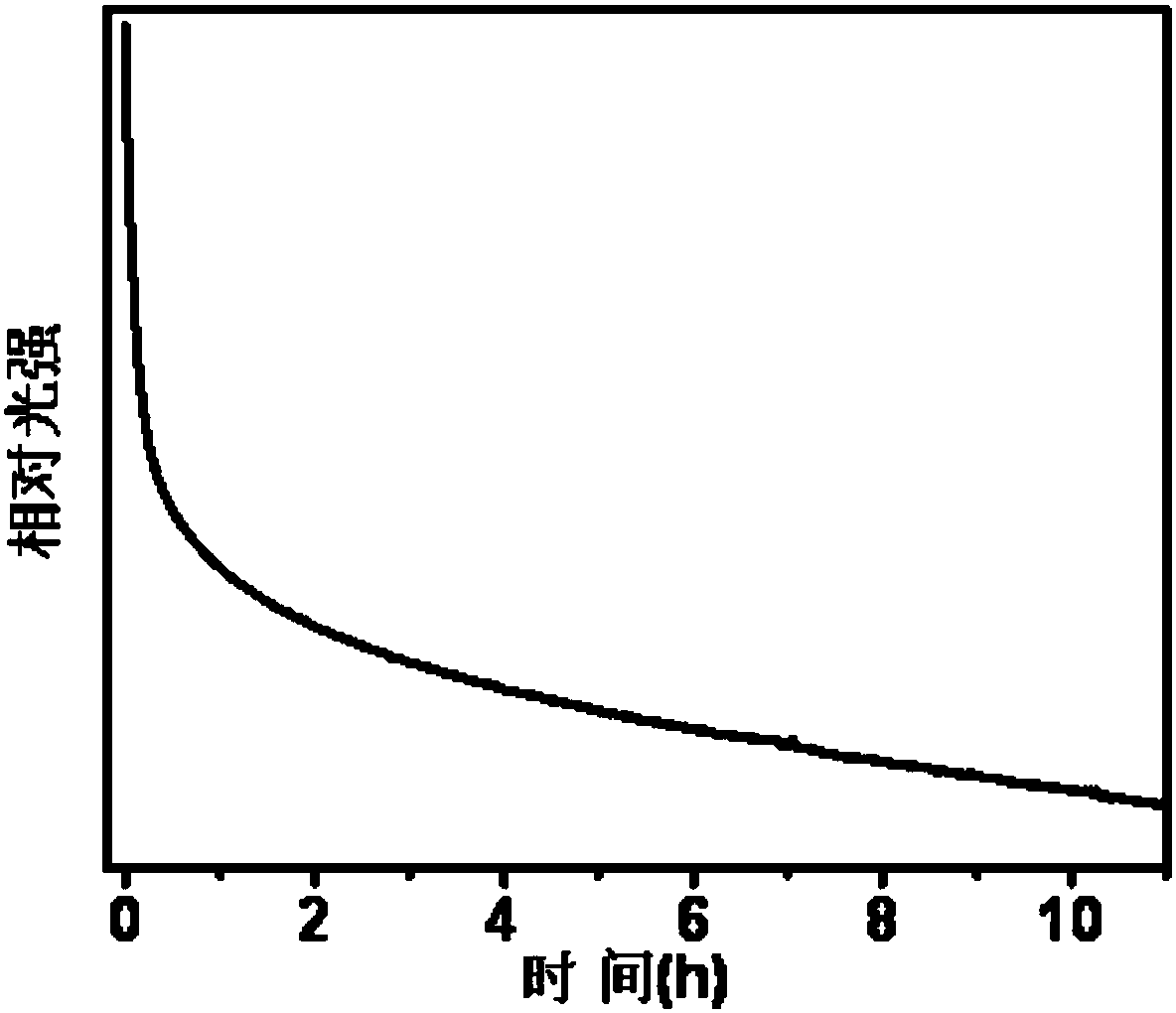

[0057] Accurately weigh the raw material CaCO according to the molar ratio 3 (analytical pure), Ga 2 o 3 (analytical pure) and MnO 2 (Analytical pure), the corresponding molar ratio is 2:4:0.004. After grinding and mixing the weighed raw materials evenly, put them in a corundum crucible, then put them into a high-temperature tube furnace, and keep them warm in the air at 1200°C After 4 hours, it was naturally cooled to room temperature to obtain a solid powder product. After testing its luminescence spectrum, under the excitation of 250nm light, it produces an orange broadband emission. The sample showed an orange afterglow for up to 11 hours after 250nm UV excitation was stopped. The emission spectrum of the product obtained in this example is as figure 1 As shown, the afterglow attenuation diagram of the obtained product is shown in figure 2 shown.

Embodiment 2

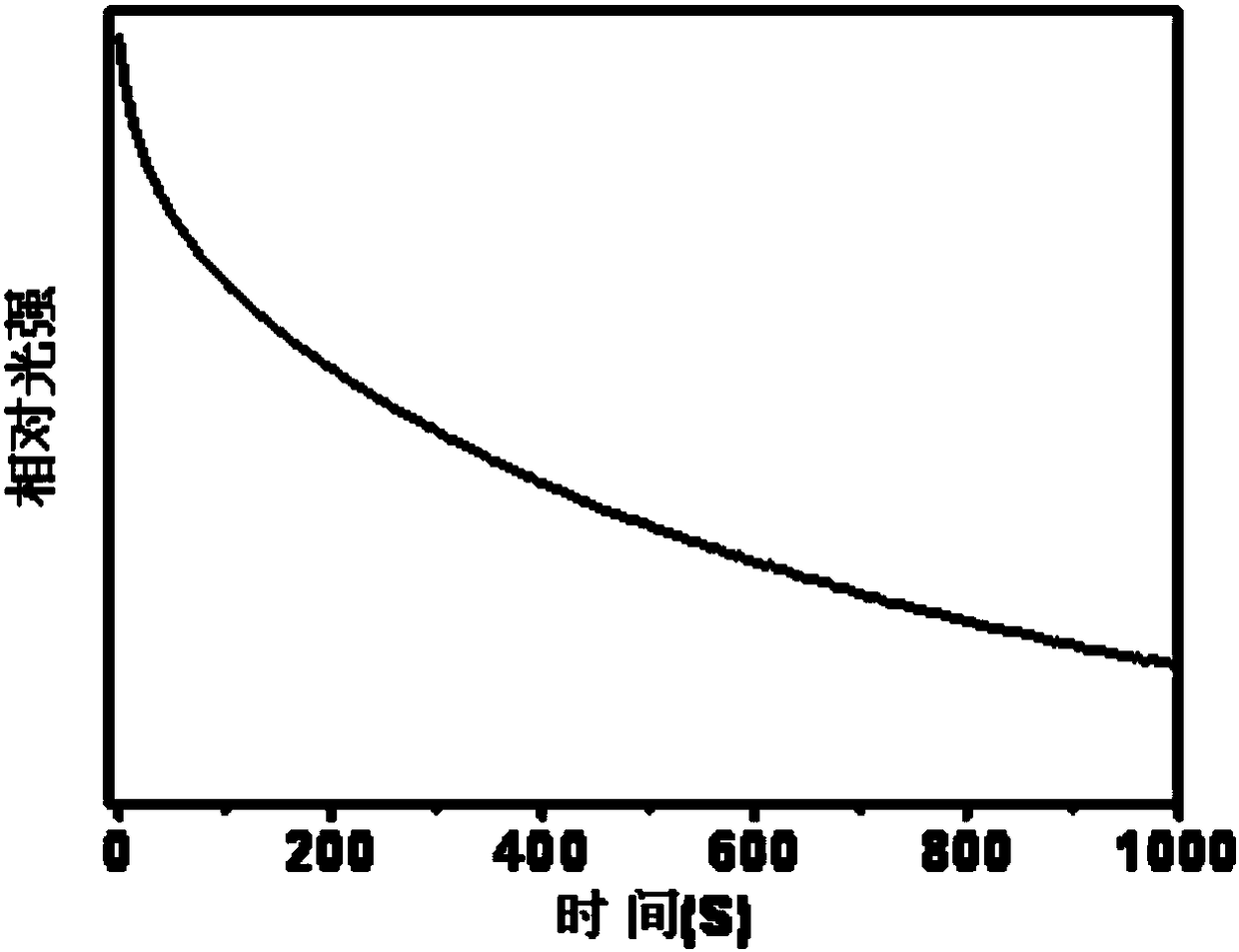

[0059] Accurately weigh the raw material CaCO according to the molar ratio 3 (analytical pure), Ga 2 o 3 (analytical pure) and MnO 2 (Analytical pure), the corresponding molar ratio is 2:4:0.01. After grinding and mixing the weighed raw materials evenly, put them in a corundum crucible, then put them into a high-temperature tube furnace, and keep them warm in the air at 1200°C After 4 hours, it was naturally cooled to room temperature to obtain a solid powder product. After testing its luminescence spectrum, under the excitation of 250nm light, it produces an orange broadband emission. The sample shows a long orange afterglow after the excitation of 250nm ultraviolet light is stopped, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com