High-low temperature lubricating grease composition and preparation method thereof

A grease composition, high and low temperature technology, applied in lubricating composition, petroleum industry, etc., can solve the problems of poor anti-wear and anti-friction of high and low temperature grease, poor high temperature performance of low temperature grease, no grease and other problems, Achieve excellent wear resistance, improve high temperature life, and high dropping point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

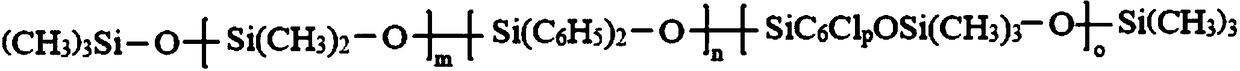

[0055] 1) 12 kilograms of chlorophenyl silicone oil (V 25 =97.33mm 2 / s, the following steps use chlorinated phenyl silicone oil with the same viscosity) and 6.88 kg of diphenylmethane-4,4'-diisocyanate into the reaction kettle, heat up and stir to 80°C ± 5°C, and then are completely dissolved;

[0056] 2) Then add 52.7 kg of chlorophenyl silicone oil into the reaction kettle, lower the temperature to 50±5°C, and slowly add 17 kg of chlorophenyl silicone oil and 5.12 kg of aniline mixed solution within 40±5 minutes to react . After the addition, react for 30±5 minutes, then slowly raise the temperature to 130-135°C, the heating time is 45±5 minutes, and then stir at constant temperature for 60±5 minutes;

[0057] 3) Then add 5 kilograms of polytetrafluoroethylene ultrafine powder, 0.5 kilograms of iron octoate, 0.5 kilograms of tricarbonyl cyclopentadienyl manganese and 0.3 kilograms of benzotriazole, stir and mix for 15 ± 5 minutes, and into the barrel;

[0058] 4) Cool ...

Embodiment 2

[0060] 1) 57.5 kilograms of chlorophenyl silicone oil (V 25 =156.49mm 2 / s, the following steps use chlorinated phenyl silicone oil with the same viscosity) and 43.1 kg of diphenylmethane-4,4'-diisocyanate into the reaction kettle, heat up and stir to 80°C ± 5°C, and then are completely dissolved;

[0061] 2) Add 259 kg of chlorophenyl silicone oil to the reaction kettle, lower the temperature to 50±5°C, and slowly add 81 kg of chlorophenyl silicone oil and 36.9 kg of p-toluidine mixed solution within 75±5 minutes Carry out the reaction, react for 60±5 minutes after the addition, then slowly raise the temperature to 130-135°C, the heating time is 60±5 minutes, and then stir at constant temperature for 90±5 minutes;

[0062] 3) Then add 15 kg of polytetrafluoroethylene superfine powder, 5 kg of iron octoate, 1 kg of benzotriazole, and 1.5 kg of 2,5-dithio-1,3,4-thiadiazole Derivatives, stirred and mixed for 15±5 minutes, discharged into the bucket;

[0063] 4) Cool naturall...

Embodiment 3

[0065] 1) 120 kilograms of chlorophenyl silicone oil (V 25 =227.17mm 2 / s, the following steps use chlorinated phenyl silicone oil with the same viscosity) and 103.2 kg of diphenylmethane-4,4'-diisocyanate into the reaction kettle, heat up and stir to 80°C ± 5°C, and make the are completely dissolved;

[0066] 2) Then add 500 kg of chlorophenyl silicone oil into the reaction kettle, lower the temperature to 50±5°C, and slowly add 146 kg of chlorophenyl silicone oil and 76.8 kg of aniline mixed solution within 80±5 minutes to react . After the addition, stir and react for 75±5 minutes, then slowly raise the temperature to 130-135°C, the heating time is 75±5 minutes, and then stir at constant temperature for 90±5 minutes;

[0067] 3) Then add 40 kg of polytetrafluoroethylene superfine powder, 12 kg of 1,1'-diacetylferrocene and 2 kg of benzotriazole derivatives in sequence, stir and mix for 15 ± 5 minutes, and discharge into the barrel;

[0068] 4) Cool naturally to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com