A kind of peracetic acid measuring test paper and its measuring method

A technology of peracetic acid and test paper, applied in the field of chemical analysis, can solve the problems of hydrogen peroxide interference, variability, inactivation, etc., and achieve the effects of good stability, fast response time, and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

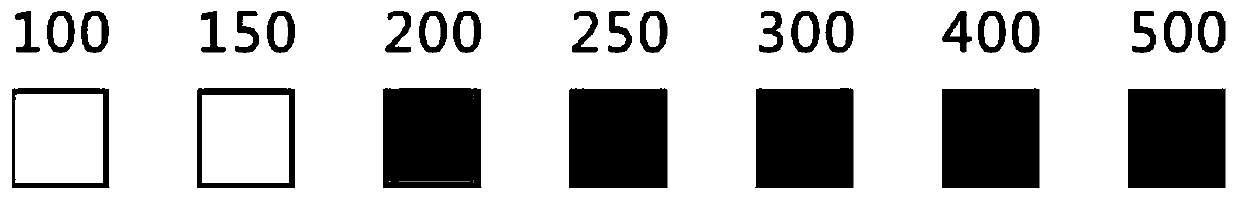

Image

Examples

Embodiment 1

[0049] The preparation method of embodiment 1 peracetic acid assay test paper

[0050] Use 80% ethanol solution to prepare 10.0g / L 4-aminoantipyrine, 4.5g / L methylparaben, 0.6g / L ferrous sulfate, 0.6g / L 5-sulfosalicylic acid, 2.0 g / L trans 1,2-cyclohexanediaminetetraacetic acid, 20.0g / L sulfamic acid mixed chromogenic solution (pH value not exceeding 2.0). The chromatographic filter paper was completely soaked in the above mixture for 10 minutes, the filter paper was taken out, and dried under vacuum at a temperature of 50°C. After drying, cut the filter paper into small pieces of 5 × 6 mm, and glue it on one end of a 5 × 80 mm strip-shaped bottom plate to make peracetic acid rapid determination test paper 1#.

Embodiment 2

[0051] The preparation method of embodiment 2 peracetic acid determination test paper

[0052] Use 80% ethanol solution to prepare 8.0g / L 4-aminoantipyrine, 3.0g / L salicylic acid, 1.0g / L manganese sulfate, 1.0g / L 5-sulfosalicylic acid, 2.0g / L antipyrine Formula 1, a mixed chromogenic solution of 2-cyclohexanediaminetetraacetic acid and 20.0g / L citric acid (pH value not exceeding 2.0). The chromatographic filter paper was completely soaked in the above mixture for 10 minutes, the filter paper was taken out, and dried under vacuum at a temperature of 50°C. After drying, cut the filter paper into small pieces of 5×6mm, and glue it on one end of a strip-shaped bottom plate of 5×80mm to make peracetic acid quick test paper 2#.

Embodiment 3

[0053] The preparation method of embodiment 3 peracetic acid determination test paper

[0054] Use 80% ethanol solution to prepare 5.0g / L 4-aminoantipyrine, 2.5g / L hydroquinone, 0.5g / L copper sulfate, 0.6g / L 5-sulfosalicylic acid, 2.5g / L A mixed chromogenic solution of trans-1,2-cyclohexanediaminetetraacetic acid and 20.0g / L sulfamic acid (pH value not exceeding 2.0). Soak the chromatographic filter paper completely in the above mixture for about 10 minutes, take out the filter paper, and dry it under vacuum at a temperature of 50°C. After drying, cut the filter paper into small pieces of 5×6mm, and glue it on one end of the strip-shaped bottom plate of 5×80mm to make peracetic acid quick test paper 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com