Glutaraldehyde test paper and rapid determination method

A technology of glutaraldehyde and test paper, which is applied in the field of chemical analysis, can solve the problems of inconvenient real-time regulation of glutaraldehyde on site and long color development time of test paper, so as to save the cost of purchasing equipment and personnel training, saving testing cost and reasonable price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

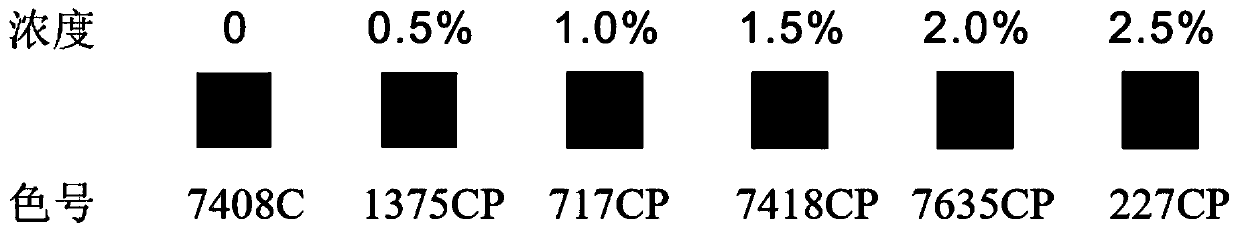

[0046] Use pure water to prepare a mixture containing 5.1g / L p-xylenolphthalein, 7.8g / L Orange G, 50.8g / L sodium sulfite, 41.8g / L allyltrimethylammonium chloride, and 1.75g / L polyvinyl alcohol Chromogenic solution. The chromatographic filter paper was completely soaked in the above mixture for 10 minutes, the filter paper was taken out, and vacuum-dried at 80°C. After drying, cut the filter paper into small pieces of 5×6 mm, and glue it to one end of a 5×80 mm strip-shaped bottom plate to make glutaraldehyde rapid test paper 2#.

Embodiment 3

[0048] Prepared with pure water containing 4.8g / L thymolphthalein, 2,4,6-trinitro-N-(2-nitrophenyl) aniline, 92.2g / L sodium sulfite, 56.8g / L dimethyldiallyl Ammonium chloride, 2.16g / L gum arabic mixed color developing solution. The chromatographic filter paper was completely soaked in the above mixture for 10 minutes, the filter paper was taken out, and vacuum-dried at 80°C. After drying, cut the filter paper into small pieces of 5×6 mm, and glue it to one end of a 5×80 mm strip-shaped bottom plate to make glutaraldehyde rapid test paper 3#.

[0049] Glutaraldehyde determination test paper embodiment 4

[0050] Use pure water to prepare a mixture containing 9.2g / L Alizarin Blue SA, 5.0g / L Alizarin Yellow GG, 32.5g / L Sodium Sulfite, 18.4g / L Benzyltributylammonium Chloride, and 2.16g / L Gum Arabic Chromogenic solution. The chromatographic filter paper was completely soaked in the above mixture for 10 minutes, the filter paper was taken out, and vacuum-dried at 80°C. After dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com