Fluorine type heat sensitive dye for heat sensitive recording materials

A heat-sensitive recording material and heat-sensitive dye technology, applied in the field of new-type fluoran heat-sensitive dyes, can solve the problems of accelerated fading of graphics and text, long storage time, long light time, etc., and achieve fast color development rate, high density, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

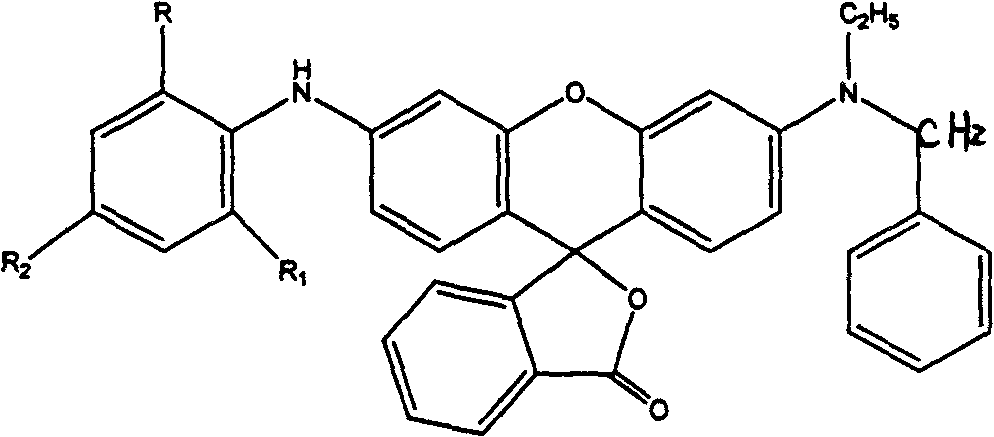

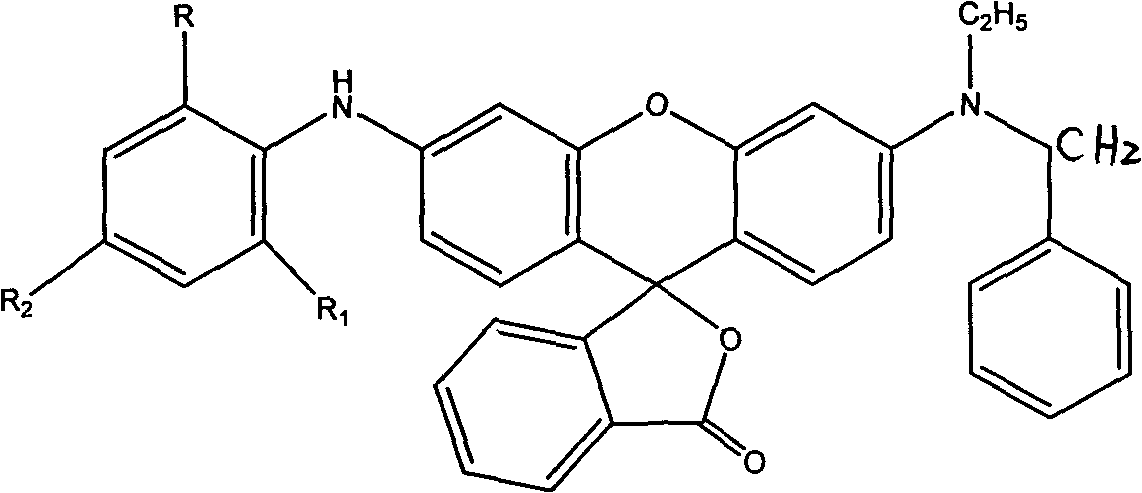

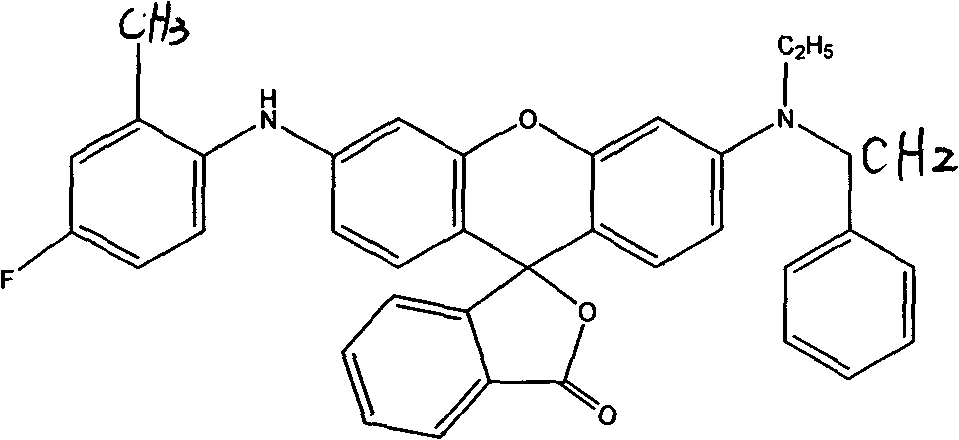

[0023] compound

[0024]

[0025] synthetic route

[0026]

[0027] 1. Synthesis of 3'6'-dichlofluororan

[0028]

[0029] Steps:

[0030] In the reactor, 157.5 g of sulfolane and 1.5 g of dimethylformamide were metered into the reactor; 50 g of fluorescein was then added, and stirring was started. Raise the temperature to 70-75°C. 71.6 g of thionyl chloride was added dropwise, and the reaction temperature was maintained at 70-75°C. During the dropwise addition, a negative pressure state was maintained in the reactor so that the thionyl chloride gas would not overflow from the reactor. After the dropwise addition was completed, the reaction was carried out for 30 minutes, during which the temperature was gradually raised to 85-90°C.

[0031] The temperature of the reaction solution was lowered to 40° C., and 200 g of 50% acetone / water solution prepared in advance was metered in for dispersion (the adding process should be carried out slowly, preferably cooling wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com