Application of iron phosphate and iron phosphate composite as anode in lithium ion battery

A technology of lithium ion battery and composite material is applied in the application field of iron phosphate and iron phosphate composite material as negative electrode in lithium ion battery, which can solve the problems of affecting battery cycle performance, high synthesis cost, over-discharge of negative electrode material, etc. The effect of good electrochemical performance, good electrochemical performance and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Active material iron phosphate (FePO 4 ) direct preparation of negative electrode and full battery

[0039] (1) Preparation of iron phosphate negative electrode

[0040] According to iron phosphate (FePO 4 ): carbon black: binder = 8:1:1 ratio (mass ratio) mixed, mixed evenly, coated on the current collector, after vacuum drying, sliced to obtain iron phosphate negative electrode.

[0041] (2) Preparation of ternary positive electrode

[0042] Mix according to the ratio (mass ratio) of ternary cathode material (nickel: manganese: cobalt = 1:1:1): carbon black: binder = 8:1:1, mix evenly, and coat on the current collector. After vacuum drying and slicing, the ternary positive electrode was obtained.

[0043] (3) Assembly of full battery

[0044] Add PP / PE / PP three-layer separator between the positive electrode and the negative electrode, and add EC:EMC:1M LiPF6 electrolyte.

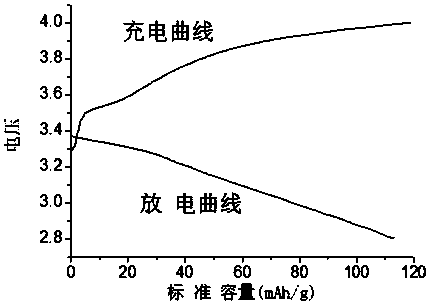

[0045] (4) Full battery test

[0046] The full battery assembled above was...

Embodiment 2

[0048] Example 2 active material iron phosphate (FePO 4 ) Preparation of negative electrode and full battery

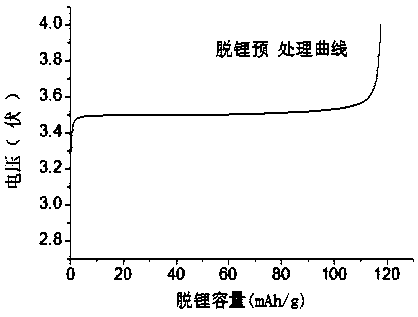

[0049] (1) Electrochemical delithiation of lithium iron phosphate electrode

[0050] According to lithium iron phosphate (LiFePO 4 ): carbon black: binder = 8:1:1 ratio (mass ratio) mixed, mixed evenly, coated on the current collector, dried in vacuum and sliced to obtain a lithium iron phosphate electrode. The lithium iron phosphate electrode and the lithium electrode are assembled into a half-cell, and the separator is a PP / PE / PP three-layer separator, and the electrolyte is added. The structure of this battery is lithium iron phosphate positive electrode-lithium negative electrode. Charge the battery with a current of 0.1 C and charge the battery to 4 V. During the charging process, lithium is gradually released and transformed into iron phosphate (FePO 4 )Material.

[0051] (2) Iron phosphate (FePO 4 ) Fabrication of the negative electrode

[0052] The a...

Embodiment 3

[0060] Example 3 active material iron phosphate (FePO 4 ) Preparation of negative electrode and full battery

[0061] (1) Chemical delithiation of lithium iron phosphate electrode

[0062] Ferric phosphate (LiFePO 4 ) dispersed in acetonitrile dissolved, adding excess NOBF 4 Deoxidize for 5 h. Remove unnecessary impurities to obtain iron phosphate (FePO 4 ) Negative electrode material.

[0063] Iron phosphate (FePO 4 ): carbon black: binder = 8:1:1 ratio (mass ratio) mixed, mixed evenly, coated on the current collector, dried in vacuum and sliced to obtain an iron phosphate electrode.

[0064] (2) Iron phosphate (FePO 4 ) of the negative electrode fabrication

[0065] The above-mentioned iron phosphate negative electrode prepared by electrochemical delithiation was taken out under a protective atmosphere in the environment, and assembled with the positive electrode obtained below to form a full battery system.

[0066] (3) Preparation of ternary cathode

[0067] Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com