Sandwich structure thermal protection material with high panel strength and making method thereof

A heat protection material and sandwich structure technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as flight reliability risk, poor strain coordination performance, easy bump damage, etc., to achieve improved panel Density and mechanical strength, as well as strain coordination performance, improved overall stability, and non-destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

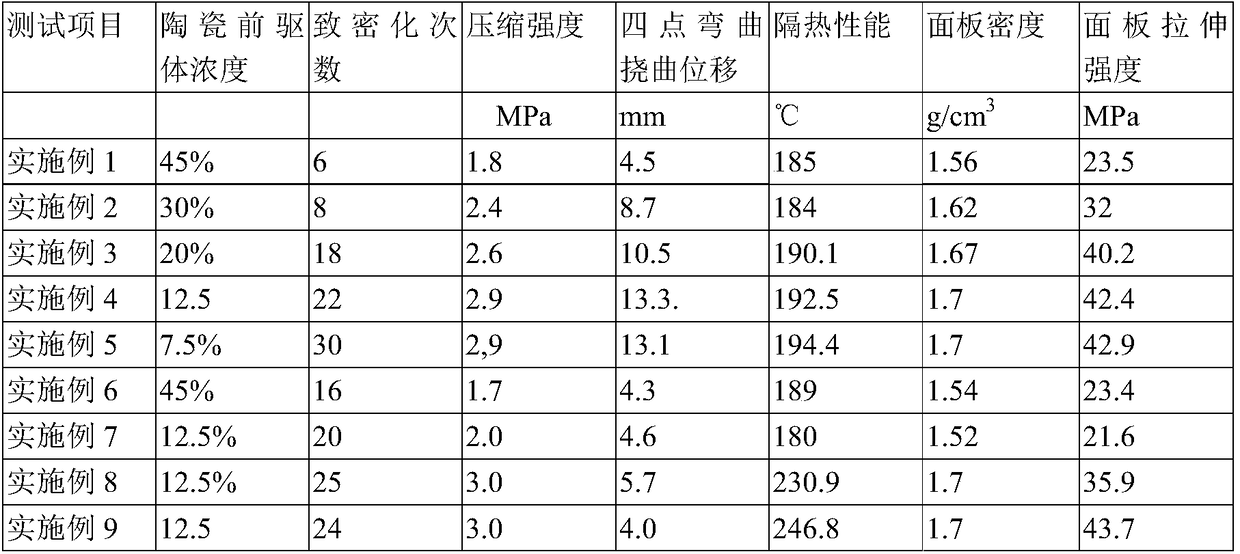

Examples

Embodiment 1

[0044] Preparation of quartz / silica sandwich structure thermal protection material with 45% concentration ceramic precursor

[0045] (1) Preparation of sandwich structure preform: first prepare aerogel composite heat insulation material with a size of 320*320*25mm, and then use ethoxytriethylsilane for hydrophobic treatment, and perform mechanical processing and perforation. Spread 2mm quartz fiber fabric and 0.5mm quartz fiber fabric on the upper and lower surfaces, and perform integrated stitching to complete the preparation of sandwich structure preform, the size is about 320*320*27.5mm.

[0046] (2) Ceramic precursor configuration: First, use a rotary evaporator to evaporate 25% silica sol until the concentration is 45% (the average particle size of the colloidal particles is 800 nm), and let it stand for use.

[0047] (3) Densification: Put the preform in a closed mold, vacuum to 0.1MPa, immerse 45% of the ceramic precursor into the mold, immerse for 24h, take it out, put it int...

Embodiment 2

[0051] Preparation of Quartz / Silicon Oxide Sandwich Structure Thermal Protection Material with 30% Concentration Ceramic Precursor

[0052] (1) Preparation of sandwich structure preform: the same as in Example 1.

[0053] (2) Ceramic precursor configuration: First, use a rotary evaporator to evaporate 25% of the silica sol until the concentration is 30% (the average particle size of the colloidal particles is 600 nm), and let it stand for use.

[0054] (3) Densification: Place the preform in a closed mold, vacuum, immerse 30% of the ceramic precursor in the mold, immerse it for 24 hours, take it out, put it into the fixture with holes on the upper and lower plates, shape it, and place it with the fixture In an oven, dry at 120°C for 8 hours. Repeat the above operation until the weight gain rate is less than 1% (repeated 8 times).

[0055] (4) Sintering and machining: same as Example 1.

[0056] The size of the obtained outer heat protection material is 300mm×300mm×27.5mm, the room tem...

Embodiment 3

[0058] Preparation of Quartz / Silicon Oxide Sandwich Structure Thermal Protection Material with 20% Concentration Ceramic Precursor

[0059] (1) Preparation of sandwich structure preform: the same as in Example 1.

[0060] (2) Ceramic precursor configuration: take a certain amount of deionized water, dilute 25% silica sol to 20% (the average particle size of colloidal particles is 150nm), and let it stand for use.

[0061] (3) Densification: Place the preform in a closed mold, vacuum, immerse 20% of the ceramic precursor into the mold, immerse it for 24 hours, take it out, put it into the fixture with holes on the upper and lower plates, shape it, and place it with the fixture. In an oven, dry at 120°C for 8 hours. Repeat the above operation until the weight gain rate is less than 1% ((repeated 18 times)).

[0062] (4) Sintering and machining: same as Example 1.

[0063] The size of the obtained outer heat protection material is 300mm×300mm×27.5mm, the room temperature compressive stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com