A kind of normal pressure preparation method of silica aerogel insulation board

A silicon dioxide and aerogel technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of poor thermal insulation of aerogel insulation boards, powder and slag removal, etc., to eliminate powder and slag. The effect of slag phenomenon, low consumption and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

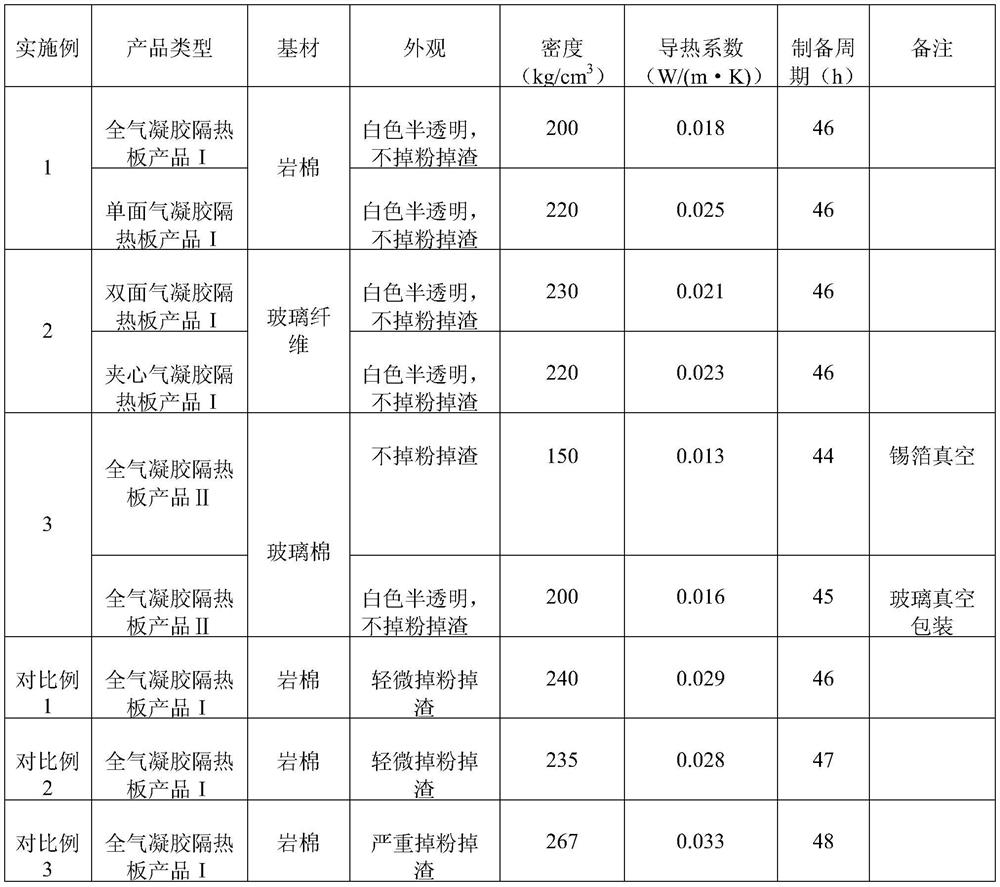

Embodiment 1

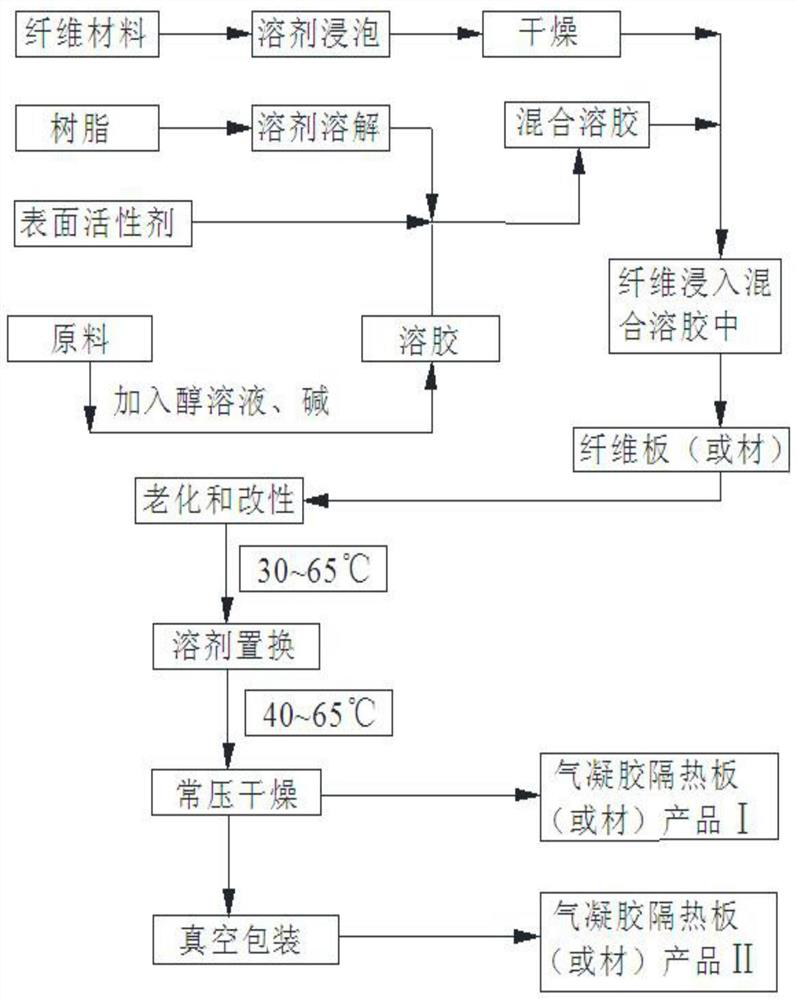

[0052] Such as figure 1 Shown, a kind of atmospheric pressure preparation method of silica airgel insulation board, comprises the following steps:

[0053] 1), the preparation of airgel:

[0054] A), resin treatment: put phenolic resin into ethanol solvent (mass concentration 95%) and fully dissolve at 50 ℃, the molar ratio of phenolic resin and ethanol solvent is 1:8;

[0055] B), preparation of sol: quickly mix ethyl orthosilicate and ethanol (mass concentration 95%) in a molar ratio of 1:15, stir at 800rpm / min for 3min to form a mixed solution, and then immediately add urea (orthosilicate The molar ratio of ethyl ester to urea is 1:0.6), stirred at 35°C and 800rpm / min for 30min to make a sol;

[0056] C), preparation of mixed gel: the phenolic resin and surfactant (KH570) processed through step A) are added in the sol prepared through step B) according to a certain mass ratio and fully mixed, the mass ratio of phenolic resin, KH570 and sol 1:0.05:20 to form a mixed sol o...

Embodiment 2

[0060] Such as figure 1 Shown, a kind of atmospheric pressure preparation method of silica airgel insulation board, comprises the following steps:

[0061] 1), the preparation of airgel:

[0062] A), resin treatment: put alkyd resin into methanol solvent (mass concentration 95%) and fully dissolve at 60°C, the molar ratio of alkyd resin to methanol solvent is 1:10;

[0063] B), preparation of sol: quickly mix methyl orthosilicate and methanol (mass concentration 95%) solution at a molar ratio of 1:18, stir at 1000rpm / min for 4min to form a mixed solution, then immediately add urea (orthosilicate The molar ratio of methyl ester to urea is 1:0.8), stirred at 40°C and 1000rpm / min for 40min to make a sol;

[0064] C), preparation of mixed gel: the alkyd resin and surfactant (KH570) processed through step A) are added in the sol prepared through step B) according to a certain mass ratio and fully mixed, the alkyd resin, KH570 and sol The mass ratio is 1:0.06:20 to form a mixed s...

Embodiment 3

[0068] Such as figure 1 Shown, a kind of atmospheric pressure preparation method of silica airgel insulation board, comprises the following steps:

[0069] 1), the preparation of airgel:

[0070] A), resin treatment: put epoxy resin into methanol solvent (mass concentration 95%) and fully dissolve at 60°C, the molar ratio of alkyd resin to methanol solvent is 1:6;

[0071] B), sol preparation: quickly mix methyltrimethoxysilane and methanol (mass concentration 95%) solution at a molar ratio of 1:20, stir at 1000rpm / min for 5min to form a mixed solution, then immediately add urea (orthosilicon The molar ratio of methyl ester to urea is 1:0.5), stirred at 45°C and 1200rpm / min for 55min to make a sol;

[0072] C), preparation of mixed gel: the epoxy resin, surfactant (KH570) processed through step A) will be added in the sol prepared through step B) according to a certain mass ratio and fully mixed, the epoxy resin, KH570 and sol The mass ratio is 1:0.07:20 to form a mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com