Porous two-dimensional zinc cadmium sulfide nanosheet as well as preparation method and application thereof

A technology of zinc cadmium sulfide and nanosheets, which is applied in chemical instruments and methods, inorganic chemistry, chemical/physical processes, etc., can solve the problems of complex preparation methods, difficult recycling of quantum dot systems, and high equipment requirements, so as to facilitate diffusion The effect of mass transfer, more reactive sites, and uniform distribution of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a porous two-dimensional Cd x Zn 1-x The preparation method of S nanosheet, comprises the following steps:

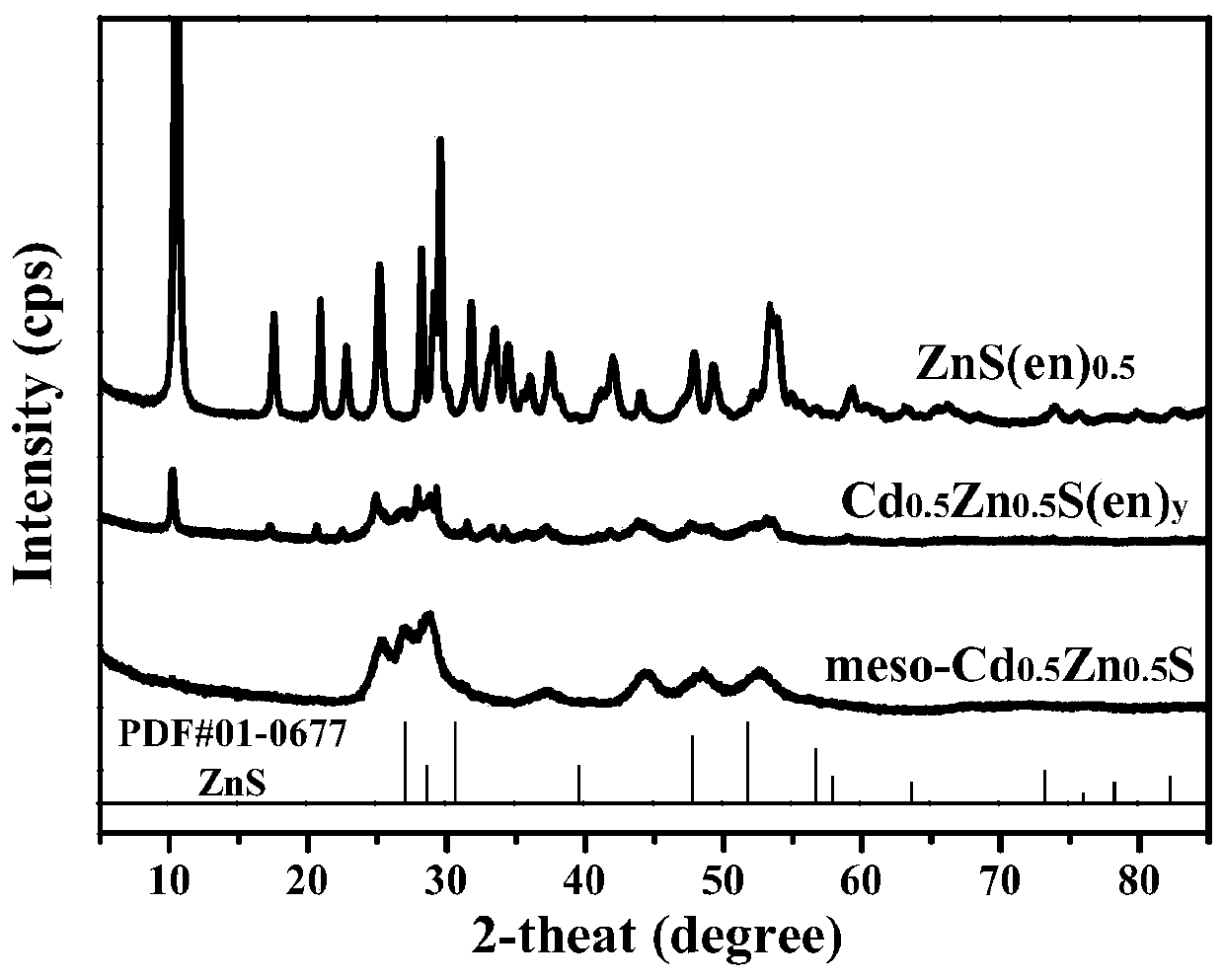

[0030] Zinc salt, ethylenediamine aqueous solution and sulfur source are mixed, carry out the first solvothermal reaction, obtain zinc sulfide-ethylenediamine (abbreviated as ZnS(en) 0.5 )Precursor;

[0031] The ZnS(en) 0.5 Precursor, cadmium salt and organic solvent are mixed, carry out the second solvothermal reaction, obtain zinc sulfide cadmium-ethylenediamine (abbreviated as Cd x Zn 1-x S(en) y )Precursor;

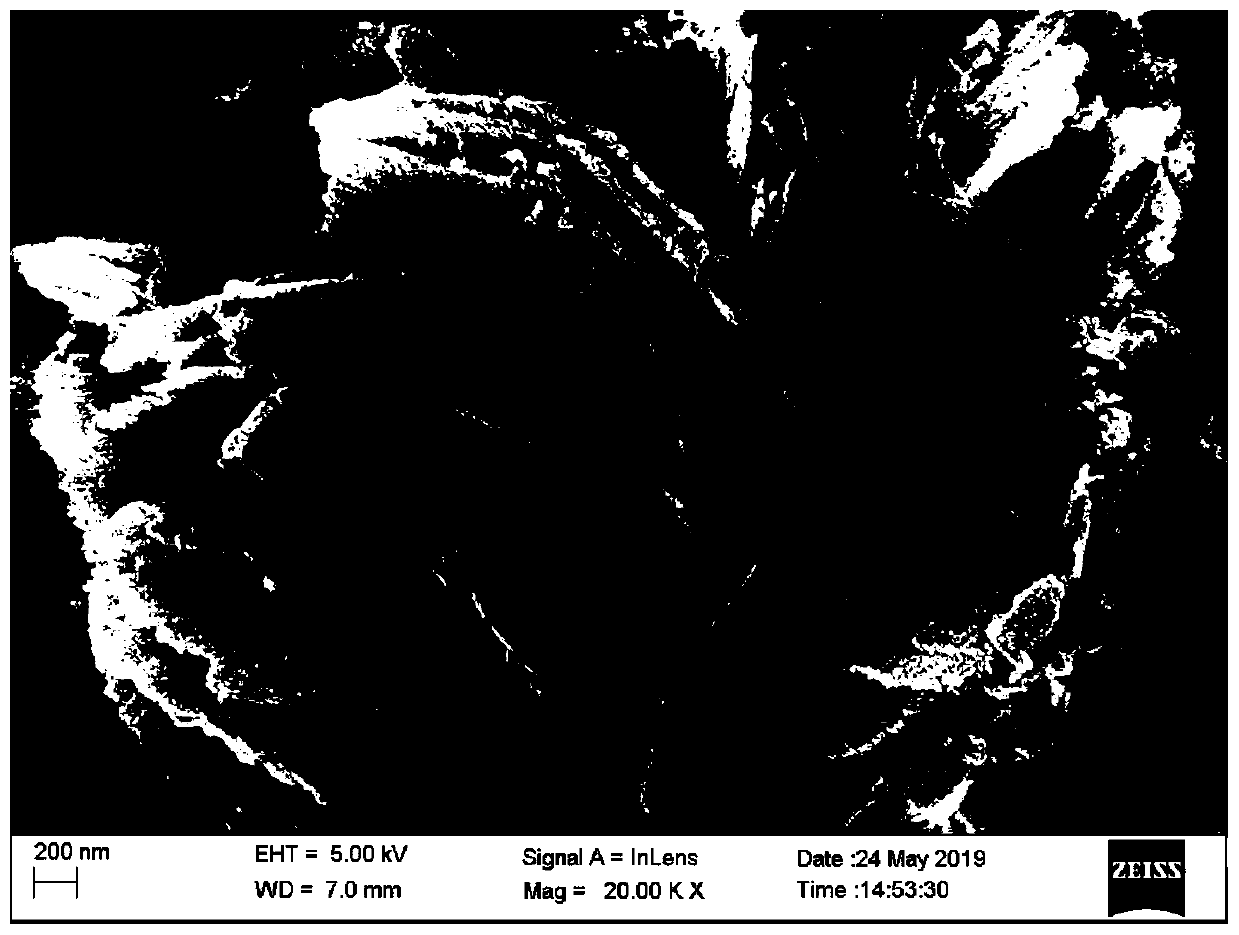

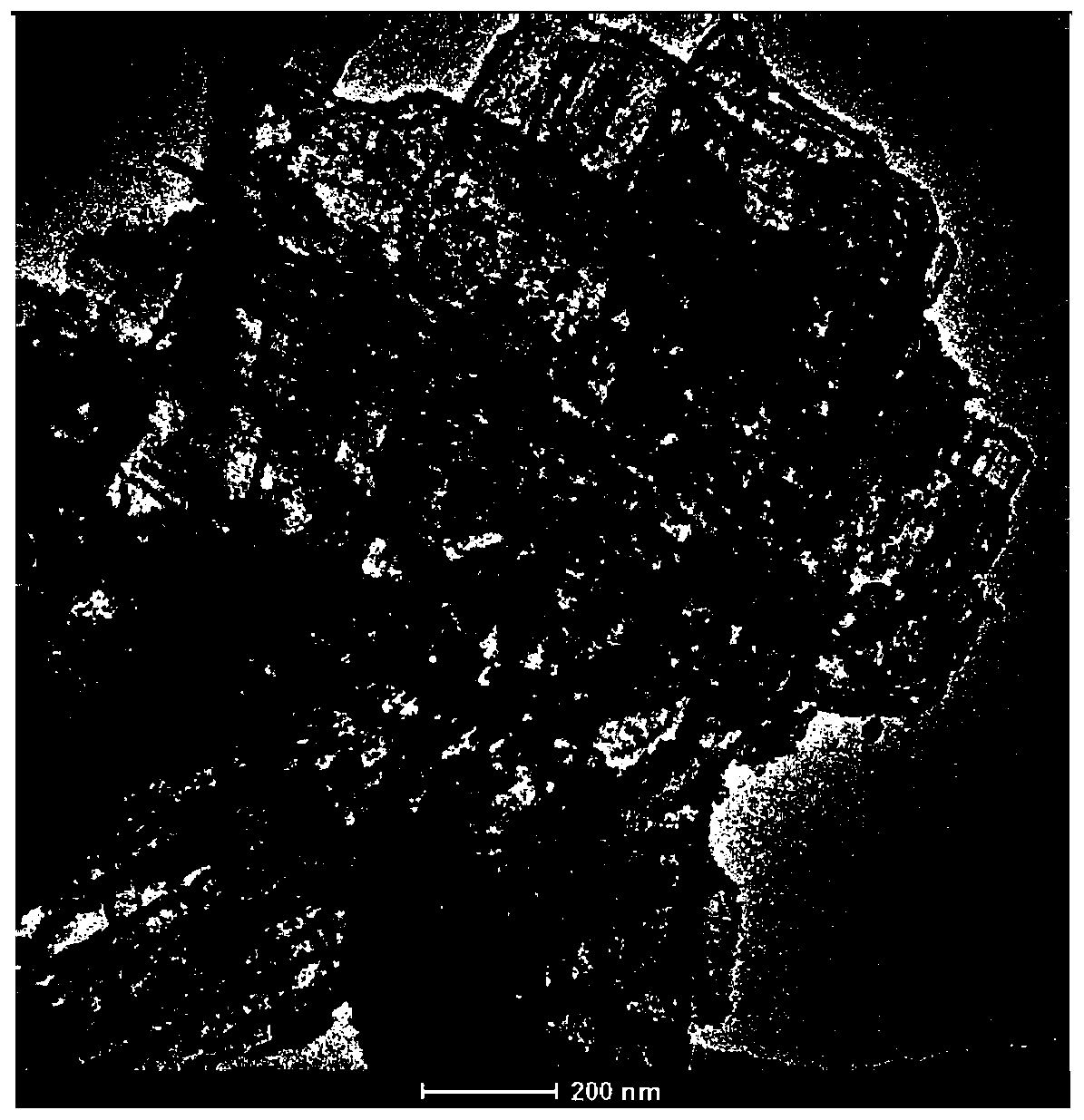

[0032] the Cd x Zn 1-x S(en) y The precursor is mixed with water for hydrothermal reaction to obtain porous two-dimensional zinc cadmium sulfide (abbreviated as Cd x Zn 1-x S, wherein, 0<x<1) nanosheets.

[0033] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0034] In the present invention, zinc salt, ethyl...

Embodiment 1

[0059] (1) Dissolve 2mmol of zinc acetate in 70mL of ethylenediamine aqueous solution (the volume ratio of ethylenediamine and water is 6:1). After the zinc acetate is completely dissolved, add 3mmol of thiourea and stir for 30min, and place the mixed system in water In a thermal reaction tank, react at 160°C for 16h, wash the obtained precursor with ethanol 5 times, and then dry at 60°C for 6h to obtain ZnS(en) 0.5 Precursor (white powder).

[0060] (2) Dissolve 160.6mg of cadmium chloride in 70mL of ethylene glycol to obtain a cadmium chloride solution, add 180mg of ZnS(en) 0.5 After the precursor was ultrasonically dispersed for 30 min, the resulting mixed solution was placed in a hydrothermal reaction tank and reacted at 160 °C for 8 h, the obtained precursor was washed with ethanol for 5 times, and then dried at 60 °C for 6 h to obtain Cd 0.5 Zn 0.5 S(en) y Precursor (yellow powder).

[0061] (3) 100mg Cd 0.5 Zn 0.5 S(en) y The precursor was mixed with 70 mL of dei...

Embodiment 2

[0065] (1) Dissolve 2mmol of zinc acetate in 70mL of ethylenediamine aqueous solution (the volume ratio of ethylenediamine and water is 6:1). After the zinc acetate is completely dissolved, add 3mmol of thiourea and stir for 30min, and place the mixed system in water In a thermal reaction tank, react at 160°C for 16h, wash the obtained precursor with ethanol 5 times, and then dry at 50°C for 8h to obtain ZnS(en) 0.5 Precursor (white powder).

[0066] (2) Dissolve 39.7mg of cadmium chloride in 70mL of ethylene glycol to obtain a cadmium chloride solution, add 100mg of ZnS(en) 0.5 The precursor was ultrasonically dispersed for 30 minutes and then stirred for 10 minutes. The resulting mixed solution was placed in a hydrothermal reaction tank and reacted at 160°C for 8 hours. The obtained precursor was washed 5 times with ethanol, and then dried at 50°C for 8 hours. get Cd 0.22 Zn 0.78 S(en) y Precursor (yellow powder).

[0067] (3) 100mg Cd 0.22 Zn 0.78 S(en) y The precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com