Microwave-synthesized oxygen vacancy BiOCl/Bi2O3 catalyst as well as preparation method and application thereof

A microwave synthesis and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as water body hazards, achieve safe reaction temperature, simple and convenient preparation steps, and good degradation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

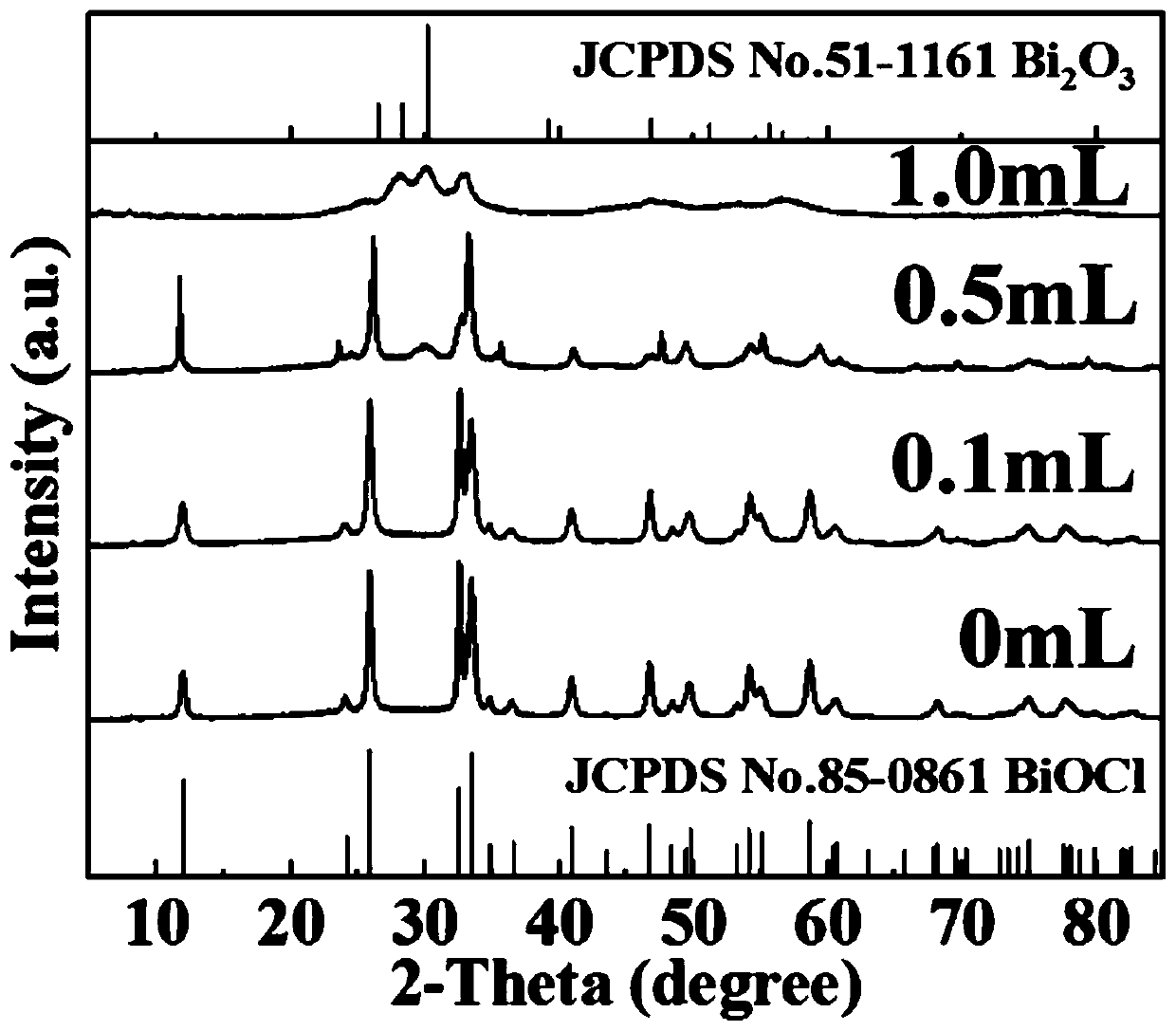

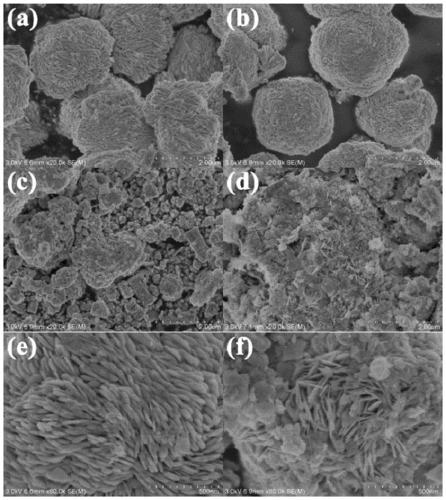

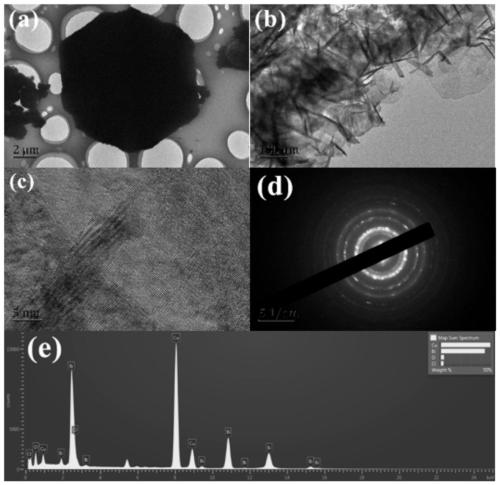

[0045] Put 0.2425g of bismuth nitrate pentahydrate (0.5mmol) and 0.07455g of potassium chloride (1mmol) in a beaker, add 30mL of ethylene glycol to it, place it on a magnetic stirrer, and stir for 60min at a speed of 500r / min , and the bismuth precursor solution is obtained after complete dissolution. All the bismuth precursor solution was placed in a microwave reactor, and under the conditions of 700r / min and 1000W, the microwave was heated to 170°C and kept for 10min to obtain precipitation. The obtained precipitate was washed with deionized water until clarified, then washed with absolute ethanol until clarified, and dried in vacuum at a temperature of 60° C. to obtain a white BiOCI catalyst powder.

Embodiment 2

[0047] Put 0.2425g of bismuth nitrate pentahydrate (0.5mmol) and 0.07455g of potassium chloride (1mmol) in a beaker, add 30mL of ethylene glycol to it, place it on a magnetic stirrer, and stir for 60min at a speed of 500r / min , and the bismuth precursor solution is obtained after complete dissolution. Put all the bismuth precursor solution in the microwave reactor, under the conditions of 700r / min and 1000W, microwave heating to 170°C and keep it warm for 10min (the first stage), then add 0.1mL sodium hypochlorite solution into the microwave reactor and Continue to incubate for 10 min (the second stage) to obtain precipitation. The obtained precipitate was washed with deionized water until clarified, then washed with absolute ethanol until clarified, and dried in vacuum at a temperature of 60°C to obtain BiOCl / Bi 2 o 3 Heterojunction catalyst White powder.

Embodiment 3

[0049] Put 0.2425g of bismuth nitrate pentahydrate (0.5mmol) and 0.07455g of potassium chloride (1mmol) in a beaker, add 30mL of ethylene glycol to it, place it on a magnetic stirrer, and stir for 60min at a speed of 500r / min , and the bismuth precursor solution is obtained after complete dissolution. Put all the bismuth precursor solution in the microwave reactor, under the conditions of 700r / min and 1000W, microwave heating to 170°C and keep it warm for 10min (the first stage), then add 0.5mL sodium hypochlorite solution into the microwave reactor and Continue to incubate for 10 min (the second stage) to obtain precipitation. The obtained precipitate was washed with deionized water until clarified, then washed with absolute ethanol until clarified, and dried in vacuum at a temperature of 60°C to obtain BiOCl / Bi 2 o 3 Heterojunction catalyst White powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com