Heat preservation plates used as environment-friendly heat preservation wall members

一种保温墙面、保温板的技术,应用在保温、建筑构件、应用等方向,能够解决河流淤塞、产生扬尘、污染大气等问题,达到耗能少、隔热效果优、成本低廉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Implementation example 1, environmental protection building insulation material, is characterized in that: batching is made up of following components by weight percentage: 50 purpose attapulgite clay tailings powder 4~21%, 100 purpose fly ash 5~10%, 200 purpose volcanic ash 3-21%, 5-10% of 70-mesh bentonite tailings powder, 2-10% of 70-mesh diatomite tailings powder, 5-15% of cement, 10-30% of liquid cold water with a temperature below 6 degrees Celsius, cement hair Foaming agent 10-15%, peat powder 2-6%, 500 mesh pure iron powder 0.5-2%;

[0046] When preparing the ingredients, add cold water to the container first, then add pure iron powder to the cold water in the container while avoiding the iron powder encountering air, and then add other ingredients;

[0047] The preparation steps are as follows:

[0048] (1) Add the ingredients into the running drum mixer and stir evenly;

[0049] (2) After stirring evenly, it is transported to the mold to make a large initial...

Embodiment 2

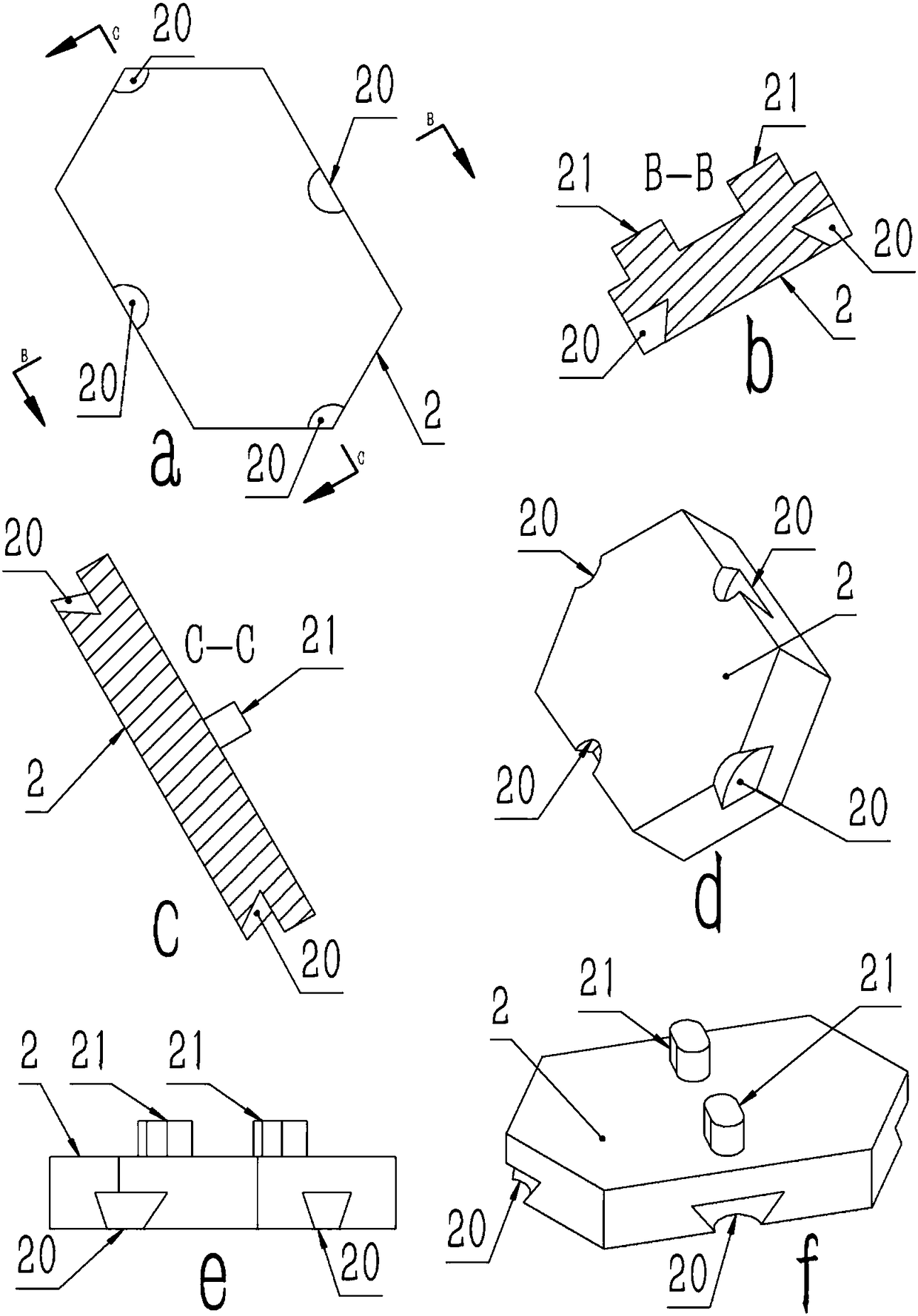

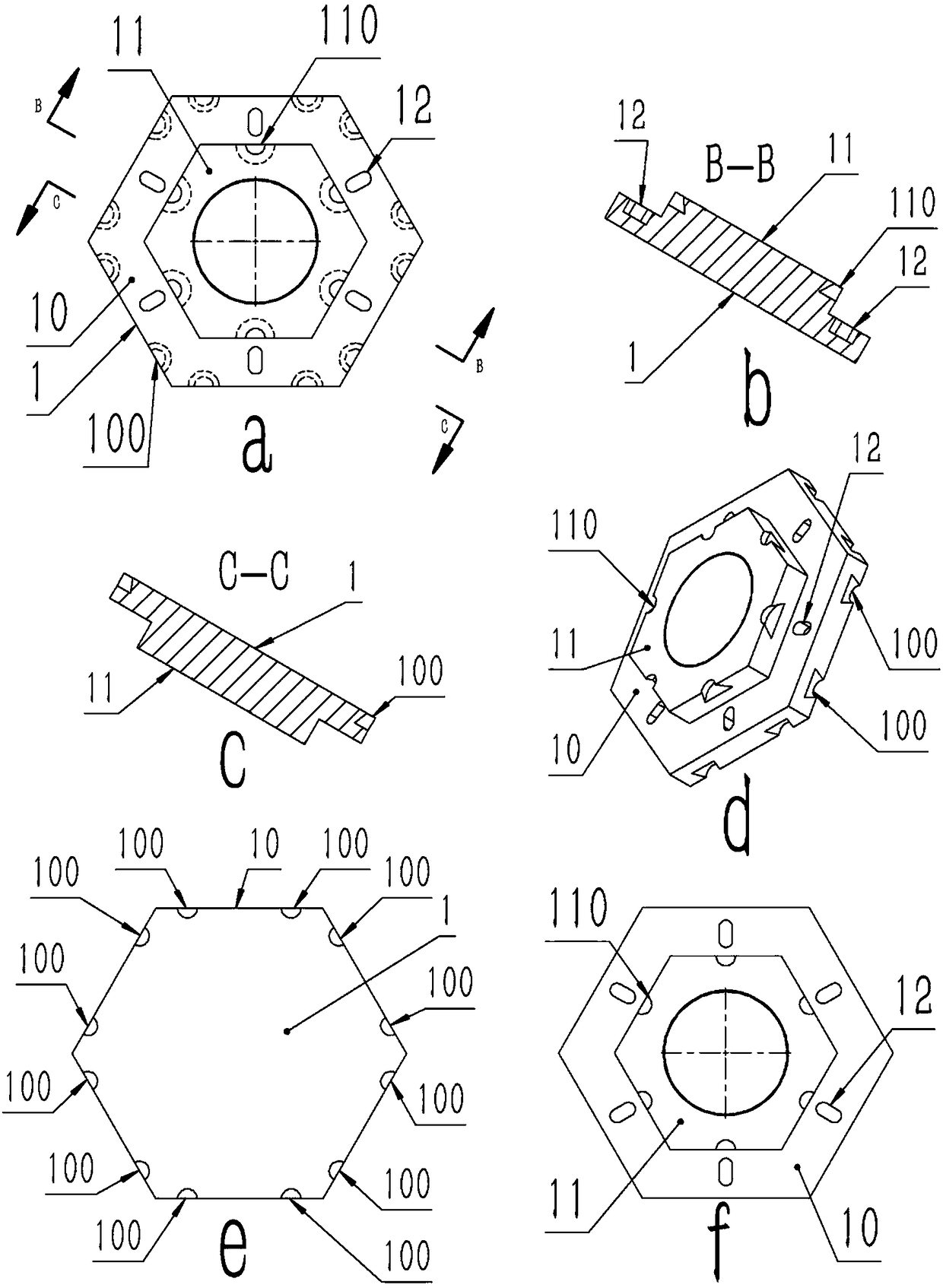

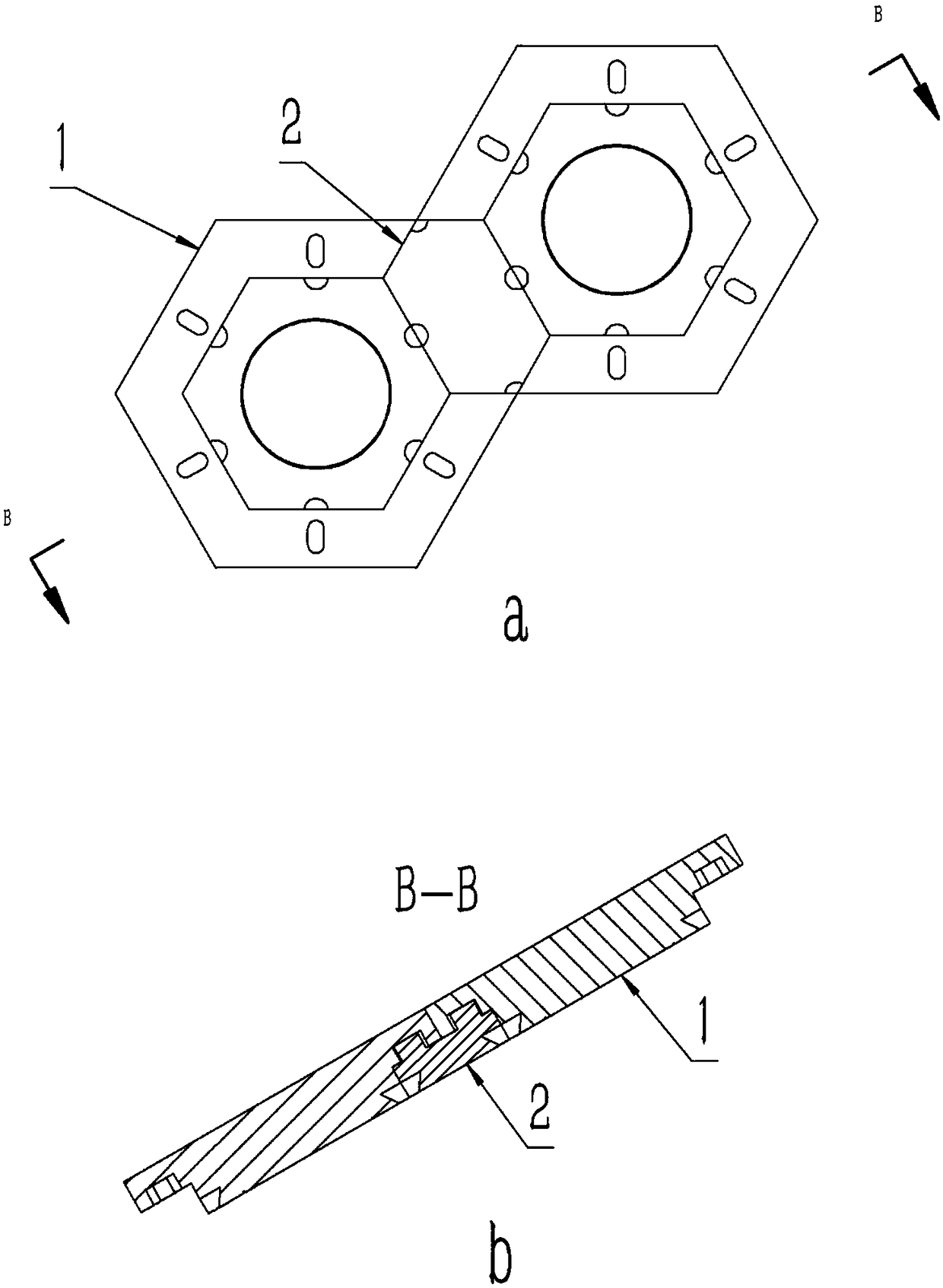

[0054] Implementation example 2, such as Figure 1-4 As shown, the environmental protection thermal insulation wall surface is characterized in that it includes at least 6 thermal insulation boards (1) and at least 6 seam masking boards (2); the thermal insulation board (1) has a lower layer body (10), an upper layer body (11), The connecting hole (12), the lower layer body (10) is a regular hexagonal prism, the upper layer body (11) is a regular hexagonal prism, and the radius of the inscribed circle of the regular hexagonal circumference of the top view figure of the upper layer body (11) is smaller than the lower layer The inscribed circle radius of the circumference of the regular hexagon of the top view figure of body (10), the axis of upper layer body (11) coincides with the axis of lower layer body (10), and the six facets of upper layer body (10) are all aligned with the lower layer The six edges of the body (11) are parallel, the bottom surface of the lower body (10) ...

Embodiment 3

[0065] Implementation example 3, brush one deck of cement mortar on the outer surface of the upper layer of implementation example 1 after being attached to the wall, and paste attractive tiles.

[0066] Other unclear parts in this description are prior art or common knowledge, so they will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com