Cobalt-doped modified vanadium phosphorus oxide supported type catalyst for catalyzing and oxidizing NO and preparation method thereof

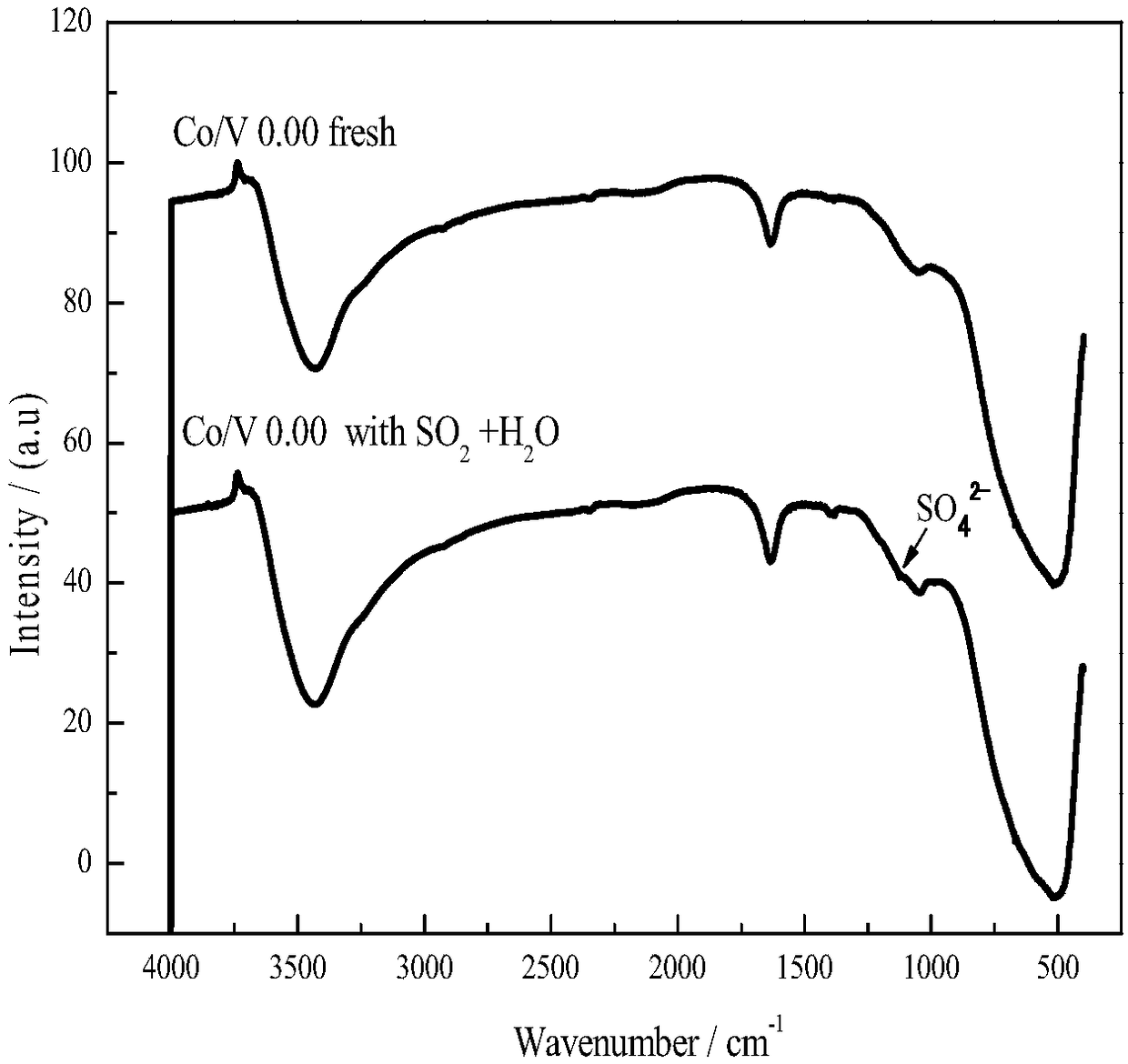

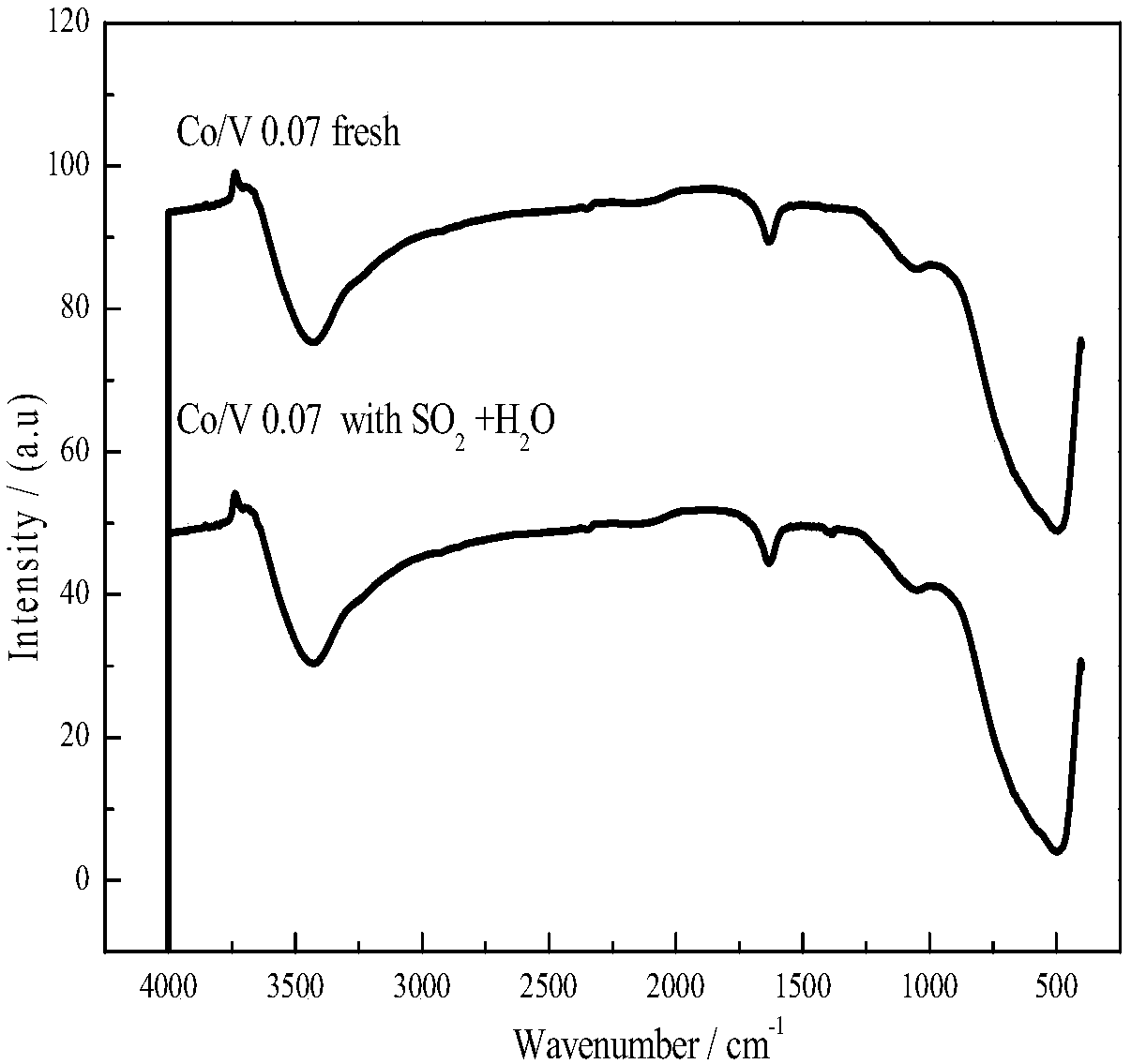

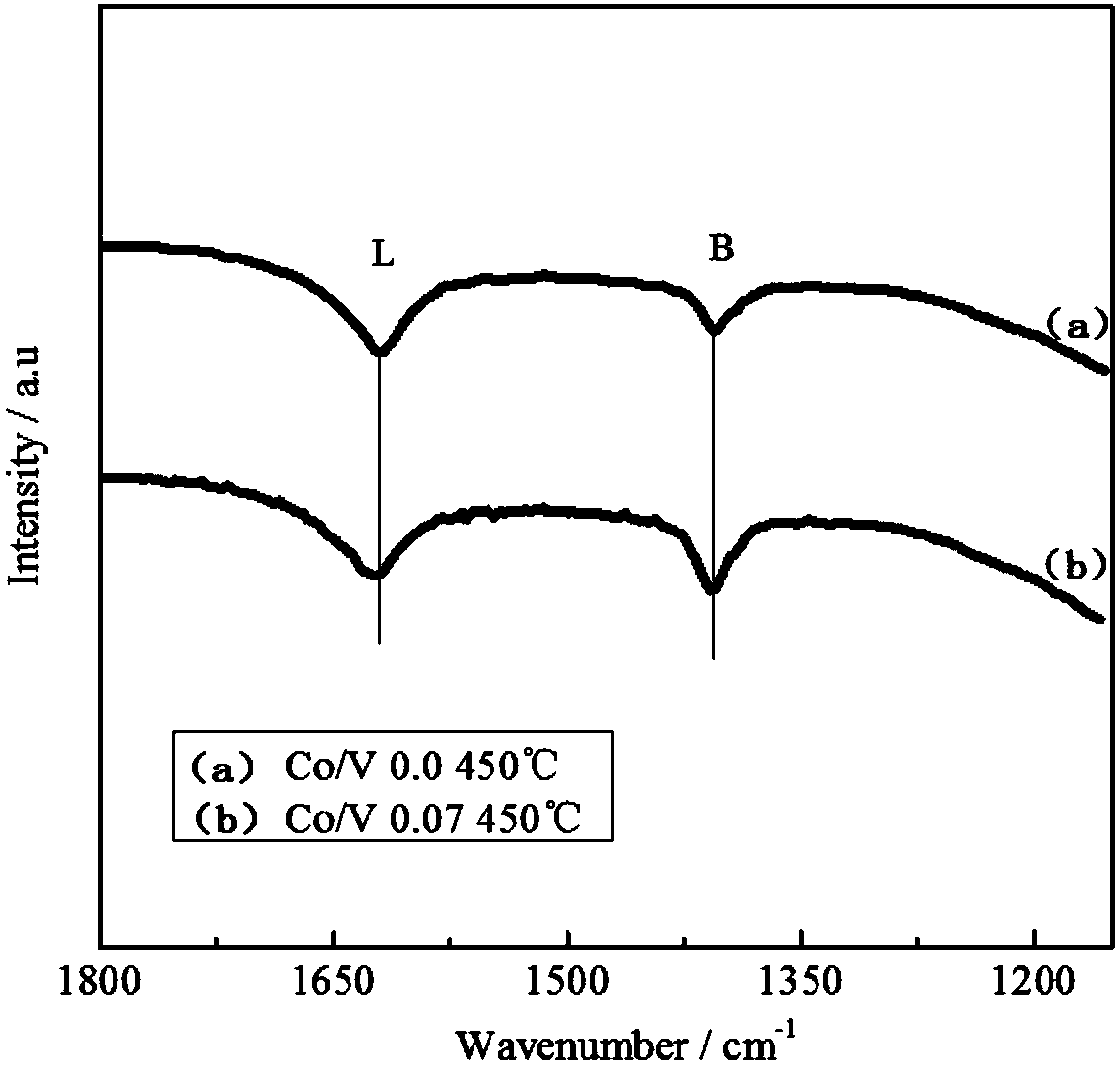

A supported catalyst, vanadium phosphorus oxide technology, applied in the field of air pollution control, can solve problems such as impact, and achieve the effect of strong ability, high NO oxidation rate, strong resistance to SO2 and water vapor poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a cobalt-modified vanadium-phosphorus oxide-supported catalyst in this embodiment specifically includes the following steps:

[0050] (1) Preparation of active component Co-VPO

[0051] The first step, weigh a certain amount of ammonium metavanadate (NH 4 VO 3 ) was calcined in a muffle furnace at 435°C for 5.5h to form V 2 o 5 . In the second step, weigh the V prepared in the first step 2 o 5 2g of powder, add it to the organic matter with isobutanol as reducing agent and benzyl alcohol as solvent, including 12ml of isobutanol and 8ml of benzyl alcohol, stir and heat to 140°C and reflux for 2.8h; the third step, to the second step Phosphoric acid (H 3 PO 4 ) and Co(NO 3 ) 2 , where NH 4 VO 3 and H 3 PO 4 The molar ratio is 1, Co(NO 3 ) 2 and NH 4 VO 3 The molar ratio is 0.08, continue stirring and heating to 145°C for reflux for 2h, then perform suction filtration, calcinate the obtained particles at 145°C for 5h, and grind them...

Embodiment 2

[0057] A method for preparing a cobalt-modified vanadium-phosphorus oxide-supported catalyst in this embodiment specifically includes the following steps:

[0058] (1) Preparation of active component Co-VPO

[0059]The first step, weigh a certain amount of ammonium metavanadate (NH 4 VO 3 ) was calcined in a muffle furnace at 447°C for 4.8h to form V 2 o 5 . In the second step, weigh the V prepared in the first step 2 o 5 2g of powder, add it to the organic matter with isobutanol as reducing agent and benzyl alcohol as solvent, including 12ml of isobutanol and 8ml of benzyl alcohol, stir and heat to 146°C and reflux for 3.5h; the third step, to the second step Phosphoric acid (H 3 PO 4 ) and Co(NO 3 ) 2 , where NH 4 VO 3 and H 3 PO 4 The molar ratio is 2, Co(NO 3 ) 2 and NH 4 VO 3 The molar ratio is 0.01, continue to stir and heat to 151°C and reflux for 1.8h, then carry out suction filtration, roast the obtained particles at 149°C for 6h, and then grind them...

Embodiment 3

[0065] A method for preparing a cobalt-modified vanadium-phosphorus oxide-supported catalyst in this embodiment specifically includes the following steps:

[0066] (1) Preparation of active component Co-VPO

[0067] The first step, weigh a certain amount of ammonium metavanadate (NH 4 VO 3 ) was calcined in a muffle furnace at 455°C for 4h to form V 2 o 5 . In the second step, weigh the V prepared in the first step 2 o 5 2g of powder, add it to the organic matter with isobutanol as reducing agent and benzyl alcohol as solvent, including 12ml of isobutanol and 8ml of benzyl alcohol, stir and heat to 155°C and reflux for 3.3h; the third step, to the second step Phosphoric acid (H 3 PO 4 ) and Co(NO 3 ) 2 , where NH 4 VO 3 and H 3 PO 4 The molar ratio is 4, Co(NO 3 ) 2 and NH 4 VO 3 The molar ratio is 0.04, continue stirring and heating to 153°C and reflux for 1.5h, then perform suction filtration, calcinate the obtained particles at 155°C for 5.5h, and grind th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com