A cf50 concrete preparation process

A preparation process and technology for concrete, applied in the field of concrete, can solve the problems of low structural strength, uneven concrete surface, ash, etc., and achieve the effect of high structural strength, not easy to crack, and avoid cracking and ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

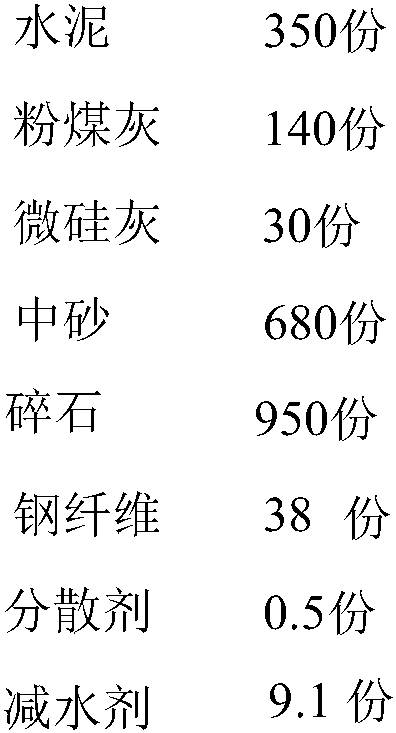

[0034] A CF50 concrete preparation process, including water, cement, fly ash, micro silica fume, medium sand, crushed stone, steel fiber, dispersant and water reducing agent; crushed stone includes small crushed stone and large crushed stone, of which large crushed stone The particle size of the stone is 5-25mm, and the particle size of the small crushed stone is 5-10mm. The steel fiber includes filament fiber and short fiber. The length of the filament fiber is about 6-8mm, and the length of the short fiber is 2-3mm.

[0035] In this example, it includes 160 parts of water, 350 parts of cement, 140 parts of fly ash, 30 parts of microsilica fume, 680 parts of medium sand, 250 parts of small gravel and 700 parts of large gravel, 30 parts of filament fibers and 8 parts of 1 part staple fiber, 0.5 part dispersant and 9.1 part water reducer.

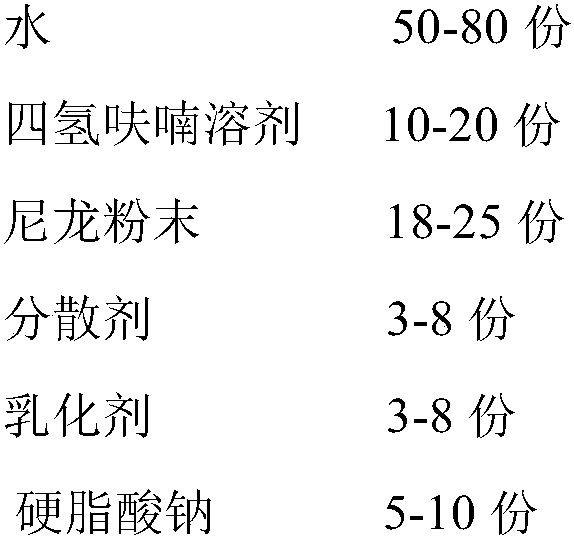

[0036] The concrete road surface after pouring the concrete obtained in this scheme is also sprayed with an adhesive hardener, and the adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com