Material for solidifying heavy metal in incineration fly ash of municipal solid waste and preparation method of material

A technology for municipal solid waste and incineration fly ash, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of little research on incineration fly ash, achieve significant innovation significance, improve dispersion characteristics, The effect of enhancing the adsorption capacity and adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

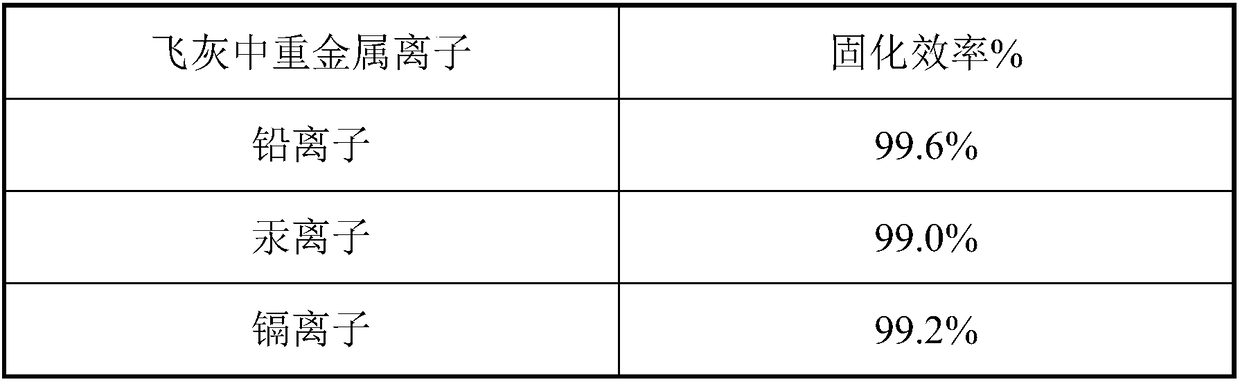

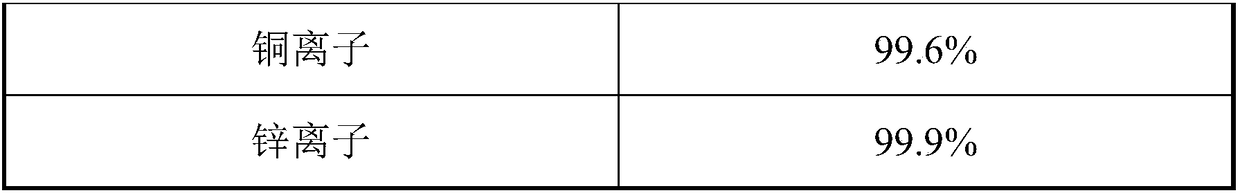

Examples

Embodiment 1

[0030] The raw materials and properties of the fly ash solidified body of a municipal solid waste incineration plant are as follows:

[0031] Portland cement: P·I 42.5 Portland cement, produced by Onoda Cement Plant, 28-day compressive strength 50.7MPa, 28-day flexural strength 8.6MPa.

[0032] Fly ash: municipal solid waste incineration fly ash, in powder form, with a particle size of 1-200 microns.

[0033] Dispersant: polyoxyethylene nonylphenyl ether, produced by Sigma-Aldrich Chemical Reagent Company of the United States, white waxy solid.

[0034] Graphdiyne nanomaterials: prepared in the school laboratory, in powder form, with a particle size of 200 nanometers to 1 micron.

[0035] Mixing water: Dalian tap water.

[0036] The preparation steps are as follows:

[0037] Using polyoxyethylene nonylphenyl ether as a dispersant, change 20% of the mixing water into hot water and add it to a beaker with a capacity of 1000mL to dissolve the dispersant. After the dispersant i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com