SBS modified asphalt waterproofing coating for building and preparation method of SBS modified asphalt waterproofing coating

A technology of modified asphalt and waterproof coatings, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, conductive coatings, etc., can solve the problems of hazards to production operators, improve corrosion resistance and aging resistance, improve elongation at break, and overall Good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

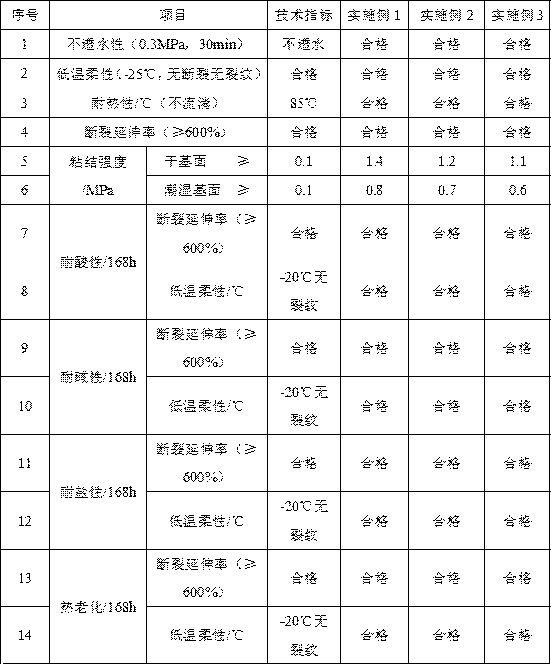

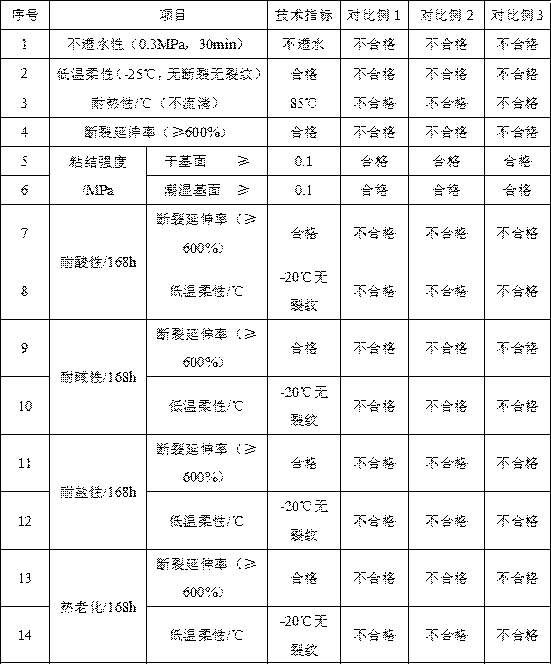

Examples

Embodiment 1

[0023] A kind of SBS modified asphalt waterproof coating for construction, made of the following raw materials in parts by weight: asphalt 50, waste engine oil 100, talcum powder 15, SBS 2, zinc aluminum alloy powder 5, phytic acid ester 1, isopropanol 3. Nano zirconium dioxide 1, C16 alcohol 1.5, glycerin 0.2, polydimethylsiloxane 0.2, benzalkonium chloride 0.01; the asphalt is a mixture of 10# asphalt and 100# asphalt in a weight ratio of 10:1; The particle size of the nano zirconium dioxide is 80-100nm; the mass percentage of each component of the zinc aluminum alloy powder is: Zn: 10%, the balance is Al and unavoidable impurities.

[0024] Described construction uses SBS modified asphalt waterproof coating, its preparation process step is:

[0025] a. Pour the waste engine oil into the reaction kettle to heat, and stir at a low speed. The stirring speed is 80 rpm to 180

[0026] Add SBS after ℃, increase the stirring speed to 150 rpm at the same time, keep the temperature...

Embodiment 2

[0030] A kind of SBS modified asphalt waterproof coating for construction, made of the following raw materials in parts by weight: asphalt 40, waste engine oil 50, talcum powder 10, SBS 3, zinc aluminum alloy powder 3, phytate 1.5, isopropanol 1. Nano zirconium dioxide 1.5, C16 alcohol 1, glycerin 0.3, polydimethylsiloxane 0.1, benzalkonium chloride 0.05; the asphalt is a mixture of 10# asphalt and 100# asphalt in a weight ratio of 10:1; The particle size of the nano zirconium dioxide is 80-100nm; the mass percentage of each component of the zinc aluminum alloy powder is: Zn: 10%, the balance is Al and unavoidable impurities.

[0031] The preparation process of the above-mentioned SBS modified bitumen waterproof coating for construction is the same as in Example 1.

Embodiment 3

[0033]A kind of SBS modified asphalt waterproof coating for construction, made of the following raw materials in parts by weight: asphalt 60, waste engine oil 150, talc powder 20, SBS 1, zinc aluminum alloy powder 8, phytate 0.5, isopropanol 5. Nano zirconium dioxide 0.5, C16 alcohol 2, glycerin 0.1, polydimethylsiloxane 0.3, benzalkonium chloride 0.01; the asphalt is a mixture of 10# asphalt and 100# asphalt in a weight ratio of 10:1; The particle size of the nano zirconium dioxide is 80-100nm; the mass percentage of each component of the zinc aluminum alloy powder is: Zn: 10%, the balance is Al and unavoidable impurities.

[0034] The preparation process of the above-mentioned SBS modified bitumen waterproof coating for construction is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com