Fiber-containing crystal, method for manufacturing fiber-containing crystal, manufacturing device for fiber-containing crystal, and chemical reagent soaking device

A manufacturing method and technology for chemical reagents, which are applied in the fields of chemical reagent soaking devices and chemical reagent soaking devices containing fiber crystals, and can solve the problems of different crystals and difficult to handle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0145]

[0146] (manufacture of fibrous crystals)

[0147] ・Preparation steps

[0148] After drying the pulp-like meta-aramid fiber, 0.02 g was suspended in 1 ml of ethanol, centrifuged at 1800 rpm for 10 seconds, and the supernatant was collected. Prepare to be formed with the hole that depth is 4mm and diameter is 8mm (the hole that loads protein solution, also called protein hole), and the hole that depth is 16mm and diameter is 17mm (hole that loads stock solution, also called reserve hole) ) plate, put 200 μl of the prepared stock solution (0.2M sodium acetate buffer (pH4.5)-5% NaCl) into the stock wells. Into the protein wells, 2 µl of the supernatant obtained above was dropped onto the bottom of the plate of the protein wells and dried to lay down fibers. The thickness (diameter) of the laid and dried fibers (meta-aramid pulp) was about 2 μm, which was about 1.2 mg. For comparison, the stock solution was similarly filled into the wells to which no fiber was laid, a...

Embodiment 2~5

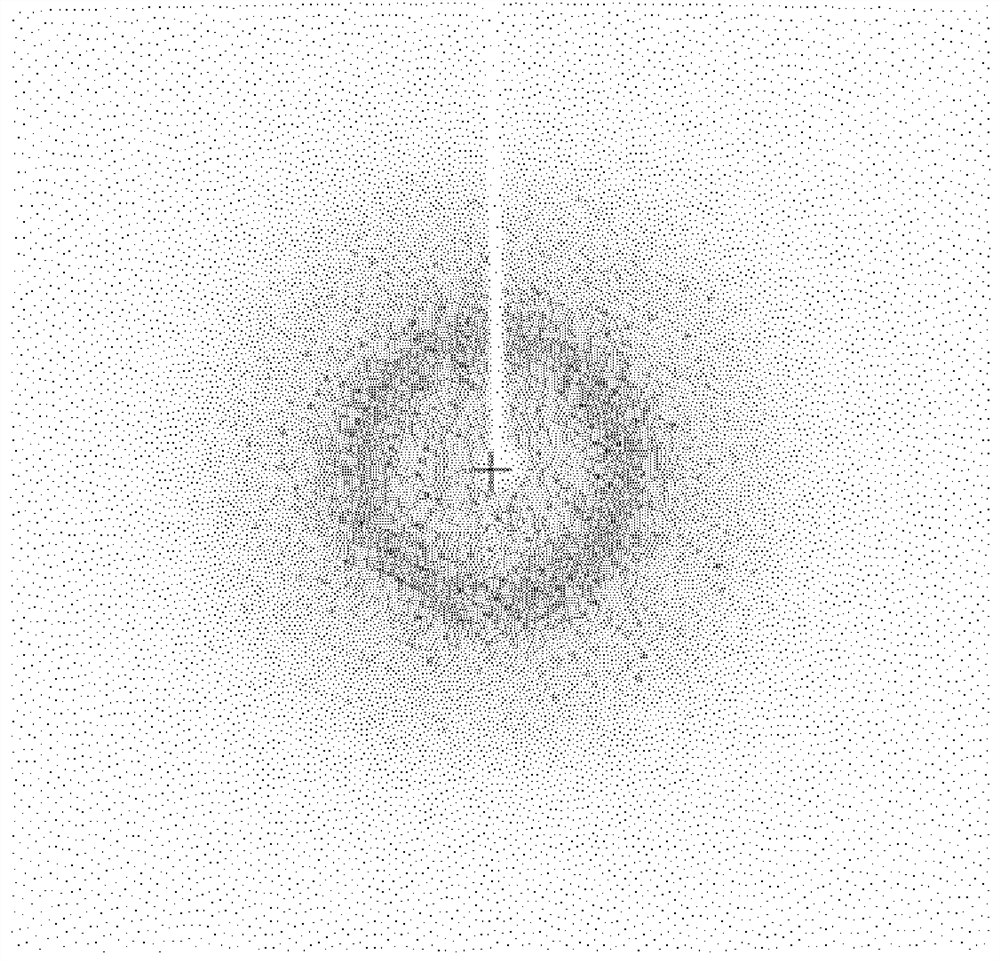

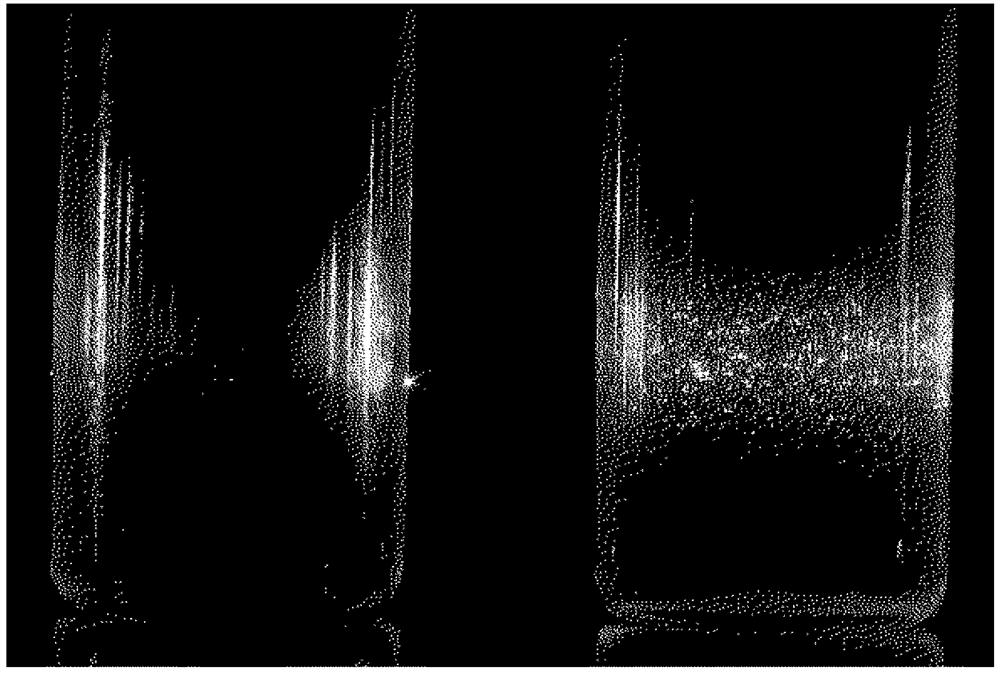

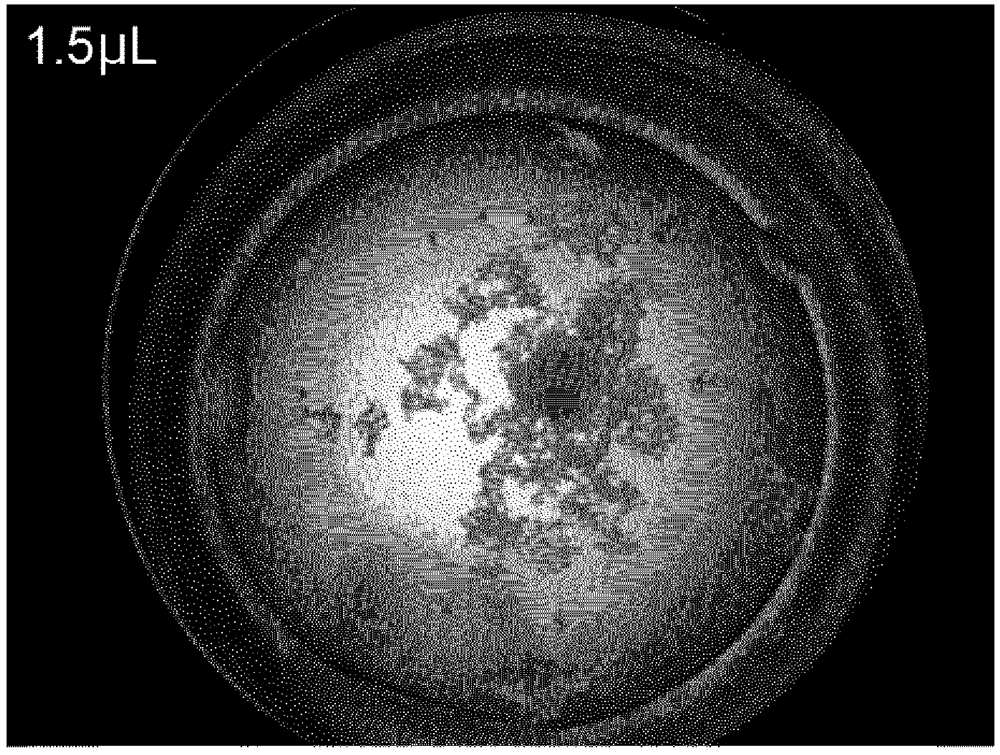

[0159] The amount of the supernatant of the fibers obtained in Example 1 was added to the wells at 0.5 μl (Example 2), 1.0 μl (Example 3), 1.5 μl (Example 4), and 2.0 μl (Example 4). 5) Except for this, by the same method as in Example 1, fiber-containing crystals were produced. The crystallization was carried out by a method of standing in an incubator at 20° C. for 1 to 3 days until crystals of about 0.2 mm were obtained. The results are shown in Figure 5~Figure 8 . Figure 5~Figure 8 These are micrographs of the fiber-containing crystals obtained in Examples 2 to 5, respectively.

[0160] Using the obtained crystals, the following immersion tests were performed. In the immersion test, 0.2M sodium acetate-5%NaCl-dimethylsulfoxide (DMSO) 40% aqueous solution was used. Each crystal formed in the hole was scooped up with a freezing ring and immersed in 0.2M sodium acetate-5%NaCl-DMSO40% aqueous solution. This was observed using a solid microscope with a magnification of 8...

Embodiment 6、7、 comparative example 2、 reference example 1

[0164]

[0165] Since crystals with different amounts of infused fibers were also obtained on boards on which the same amount of fibers were laid, the soaking test was similarly performed on these. That is, among the fiber-containing crystals formed on the pores, the fiber-containing crystals (Example 6) containing many fibers and the fiber-containing crystals (Example 6) in which no fibers were observed were extracted under a solid microscope at a magnification of 80 times. Example 7), the soaking test was carried out in the same manner as in Example 2. In addition, as Comparative Example 2, the fiber-free crystal obtained in Comparative Example 1 was extracted, and the immersion test was performed in the same manner. As a result, the time until the appearance of the crystal collapsed was 100 seconds (Example 6), 40 seconds (Example 7), and 20 seconds (Comparative Example 2).

[0166] That is, it is presumed that when a large amount of fiber-containing crystals containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com