Photoresist stripping solution

A technology of photoresist and stripping solution, which is applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve problems such as insufficient performance, white turbidity and curing of the stripping solution, and achieve stability over time Excellent, excellent solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14、 comparative example 15

[0068] Each component was mixed in the weight ratio shown in following Table 2, and the photoresist stripping liquid was obtained. About the obtained photoresist stripping liquid, the liquid state, resist stripping property, and temporal stability were evaluated by the method mentioned later. The results are shown in Table 2.

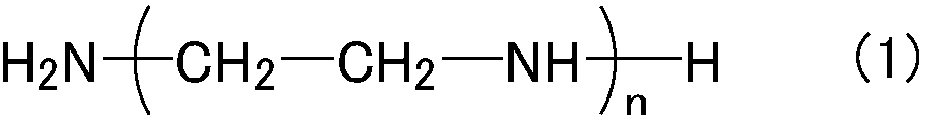

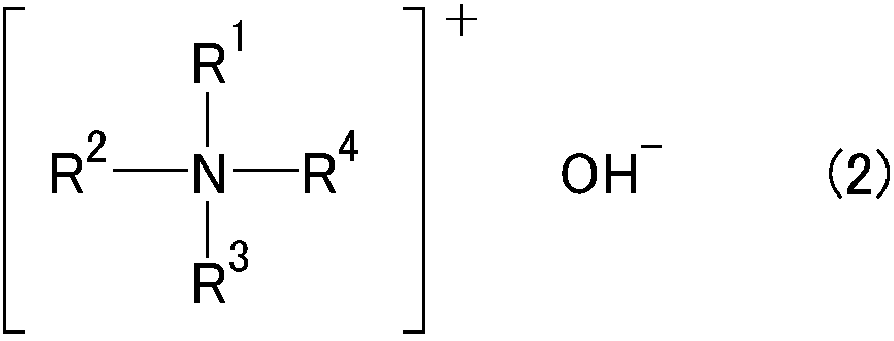

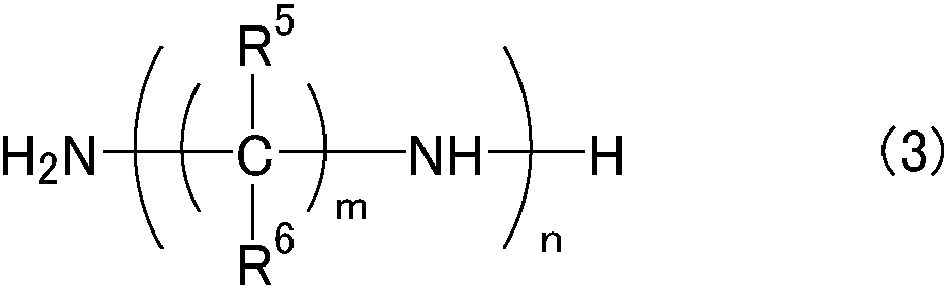

[0069] It should be noted that in Table 2, DMSO means dimethylsulfoxide, TMAH means tetramethylammonium hydroxide, EDA means ethylenediamine, DETA means diethylenetriamine, TETA means triethylenetetramine, TEPA stands for tetraethylenepentamine, PEHA stands for pentaethylenehexamine, and TEG stands for triethylene glycol.

[0070]

Embodiment 15~27

[0072] Each component was mixed in the weight ratio shown in following Table 3, and the photoresist stripping liquid was obtained. About the obtained photoresist stripping liquid, the liquid state, resist stripping property, and temporal stability were evaluated by the method mentioned later. The results are shown in Table 3.

[0073] It should be noted that in Table 3, DMSO represents dimethylsulfoxide, TMAH represents tetramethylammonium hydroxide, TETA represents triethylenetetramine, and TEG represents triethylene glycol.

[0074]

Embodiment 28~35

[0075] (Examples 28-35, Comparative Examples 16-20)

[0076] Each component was mixed in the weight ratio shown in following Table 4, and the photoresist stripping liquid was obtained. About the obtained photoresist stripping liquid, the liquid state, the SP value of a polyhydric alcohol etc., resist stripping property, and temporal stability were evaluated by the method mentioned later. The results are shown in Table 4.

[0077] It should be noted that in Table 4, DMSO stands for dimethylsulfoxide, TMAH stands for tetramethylammonium hydroxide, TETA stands for triethylenetetramine, EDA stands for ethylenediamine, MEA stands for monoethanolamine, and TEG stands for triethylenediamine alcohol.

[0078]

[0079] (Evaluation method)

[0080] 1. Liquid state

[0081] Regarding the photoresist stripping liquid, the presence or absence of precipitates and the fluidity of the liquid were visually observed, and evaluated according to the following criteria.

[0082] ◯: There i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com