Preparation of iron-based catalyst for preparing alpha-alkene from carbon dioxide through hydrogenation, catalyst and application

A technology of iron-based catalyst and carbon dioxide, which is applied in the direction of catalyst activation/preparation, hydrocarbon production from carbon oxides, carbon compound catalysts, etc. It can solve the problems of non-green, economical, waste of energy, complicated process, etc., and reduce the cost of catalysts , Simplified complex procedures, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

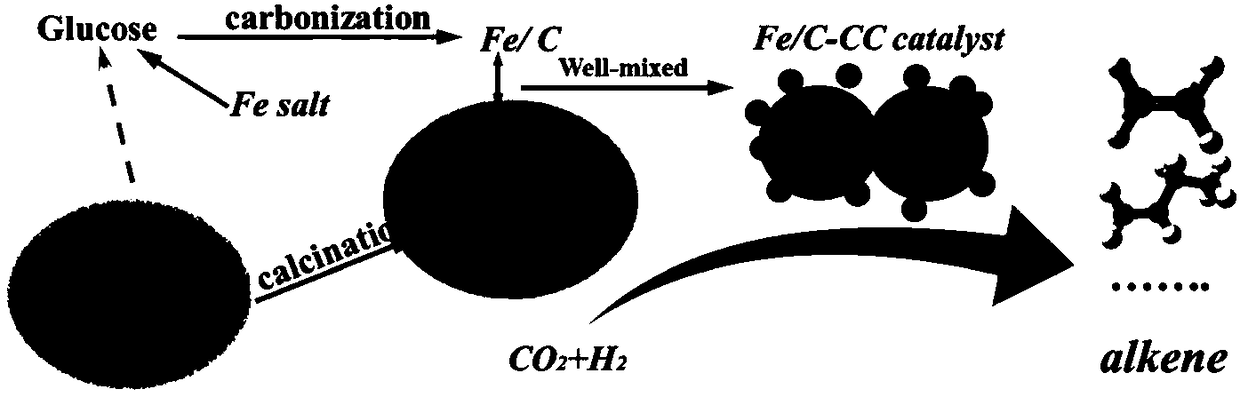

[0023] Carbon dioxide hydrogenation catalyst preparation process is as follows:

[0024] Fresh corn cob powder is first pretreated by roasting at 500°C for 3 hours in a flowing air atmosphere to remove carbon-containing organic compounds and obtain khaki additives rich in trace minerals powder. Using a one-step hydrothermal synthesis method, weigh 4.50 g of glucose and 5.10 g of ferric nitrate nonahydrate, dissolve them in deionized water, and stir them thoroughly for 1 hour. The resulting mixed solution was transferred to a 100 mL hydrothermal synthesis reactor with a polytetrafluoroethylene liner. The reactor is sealed and transferred to a hydrothermal synthesis device (also known as a homogeneous reactor). The condition control of the hydrothermal synthesis process is 120° C. for 20 hours. The obtained products were washed several times with deionized water and absolute ethanol, respectively. Finally, the product is dried for more than 12 hours, taken out and recorded a...

Embodiment 2

[0028] Carbon dioxide hydrogenation catalyst preparation process is as follows:

[0029] Fresh corn cob powder is first pretreated by roasting at 500°C for 3 hours in a flowing air atmosphere to remove carbon-containing organic compounds and obtain khaki additives rich in trace minerals powder. Using a one-step hydrothermal synthesis method, weigh 4.50 g of glucose and 5.10 g of ferric nitrate nonahydrate, dissolve them in deionized water, and stir them thoroughly for 1 hour. The resulting mixed solution was transferred to a 100 mL hydrothermal synthesis reactor with a polytetrafluoroethylene liner. The reactor is sealed and transferred to a hydrothermal synthesis device (also known as a homogeneous reactor). The condition control of the hydrothermal synthesis process is 120° C. for 20 hours. The obtained products were washed several times with deionized water and absolute ethanol, respectively. Finally, the product is dried for more than 12 hours, taken out and recorded a...

Embodiment 3

[0032] Carbon dioxide hydrogenation catalyst preparation process is as follows:

[0033] Fresh corn cob powder is first pretreated by roasting at 500°C for 3 hours in a flowing air atmosphere to remove carbon-containing organic compounds and obtain khaki additives rich in trace minerals powder. Using a one-step hydrothermal synthesis method, weigh 4.50 g of glucose and 5.10 g of ferric nitrate nonahydrate, dissolve them in deionized water, and stir them thoroughly for 1 hour. The resulting mixed solution was transferred to a 100 mL hydrothermal synthesis reactor with a polytetrafluoroethylene liner. The reactor is sealed and transferred to a hydrothermal synthesis device (also known as a homogeneous reactor). The condition control of the hydrothermal synthesis process is 120° C. for 20 hours. The obtained products were washed several times with deionized water and absolute ethanol, respectively. Finally, the product is dried for more than 12 hours, taken out and recorded a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com