A Laser Forming Method of Gradient Composite Structure

A laser forming and composite structure technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of interface cracking between transition layers, large interlayer stress of transition layers, low strength of transition layers, etc. Small stress, continuous transition of components, and the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare TA15 alloy and Ti2AlNb alloy gradient composite structural parts (size 50*50*60) using laser three-dimensional forming technology. The equipment used is laser three-dimensional forming equipment, which includes 4KW carbon dioxide fast axial flow laser, powder feeding system, purification system, and numerical control When the system uses laser three-dimensional forming technology to manufacture parts, the titanium alloy powder used is produced by plasma rotating electrode atomization method, with a particle size of about 90-400μm.

[0039] The steps are shown in 5:

[0040] 1. Initialize the laser forming equipment

[0041] Turn on the laser for preheating, perform the inspection and preparation of each system of the laser forming equipment as required, and load TA15 alloy and Ti2AlNb alloy powder into powder feeding tanks 1 and 2 respectively.

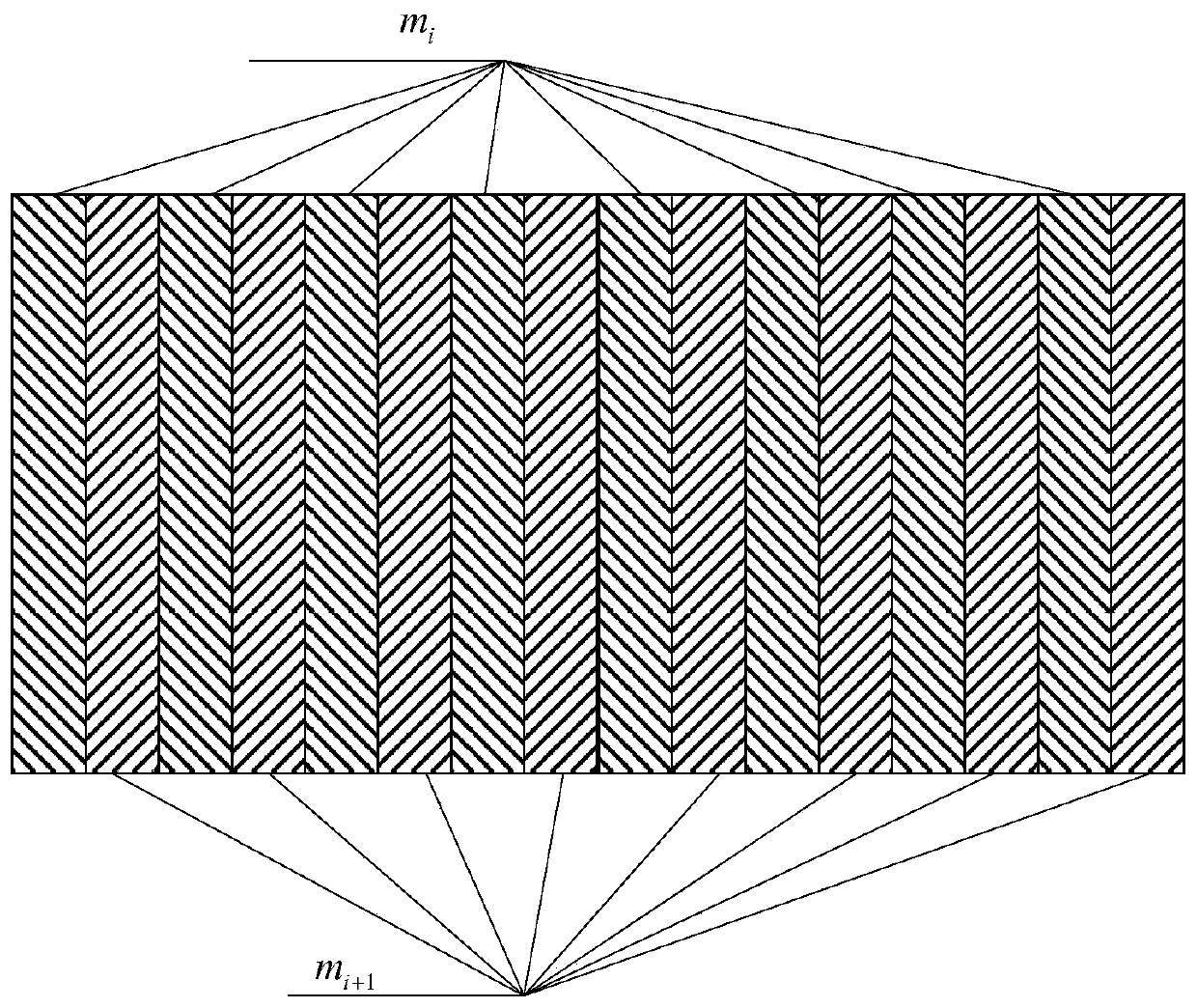

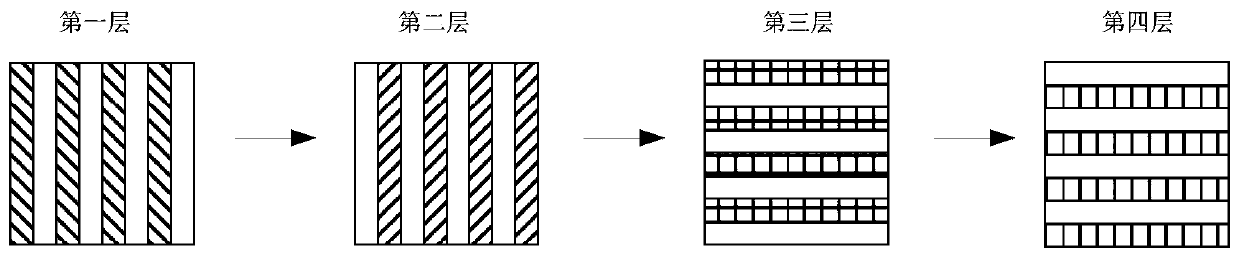

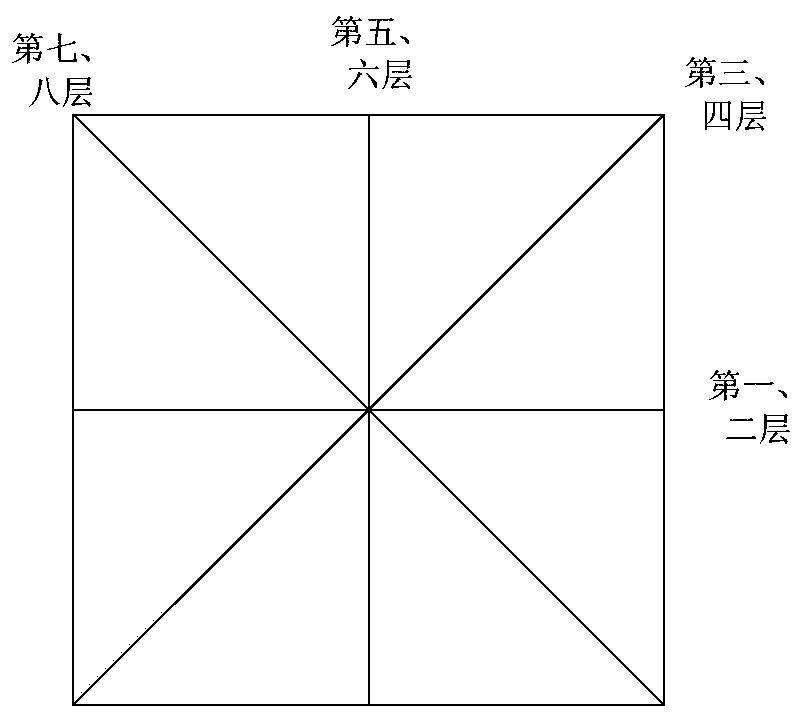

[0042] 2. Scanning trace design of TA15 alloy and Ti2AlNb alloy transition layer

[0043] After the cladding of the entire TA1...

Embodiment 2

[0053] This example uses laser three-dimensional forming technology to prepare and manufacture TA15, Ti2AlNb titanium alloy gradient composite structure samples with a size of Φ130mm×200mm. The equipment used is laser three-dimensional forming equipment, which includes 4KW carbon dioxide fast axial flow laser, powder feeding system, purification System, numerical control system, when using laser three-dimensional forming technology to manufacture parts, the titanium alloy powder used is produced by plasma rotating electrode atomization method, and the particle size is about 90-400μm.

[0054] Proceed as follows:

[0055] 1. Initialize the laser forming equipment

[0056] Turn on the laser for preheating, perform the inspection and preparation of each system of the laser forming equipment as required, and load TA15 alloy and Ti2AlNb alloy powder into powder feeding tanks 1 and 2 respectively.

[0057] 2. Scanning trace design of TA15 alloy and Ti2AlNb alloy transition layer

[0058] Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com