Rotary liquid sand blasting machine

A liquid sand blasting and rotary technology, which is applied in the direction of spray guns, explosion generating devices, abrasives, etc., can solve the problems that rotary liquid sand blasting machines are rare, and achieve the effects of novel structure, environmental pollution and reliable functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

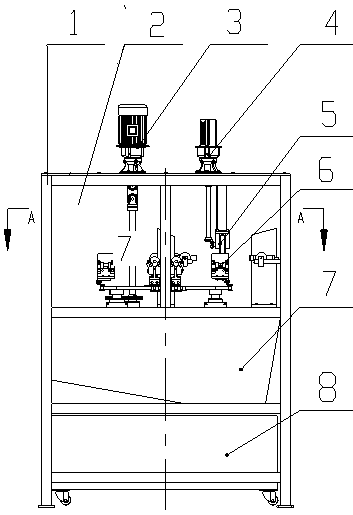

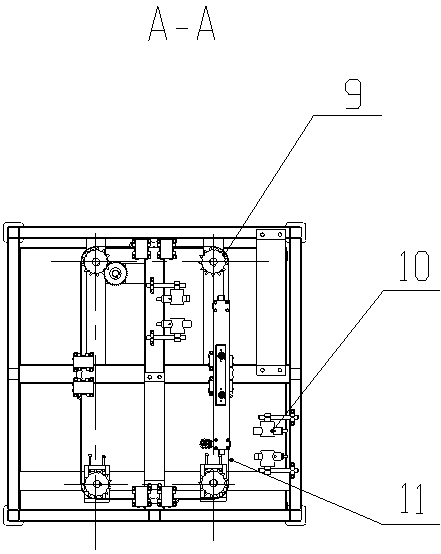

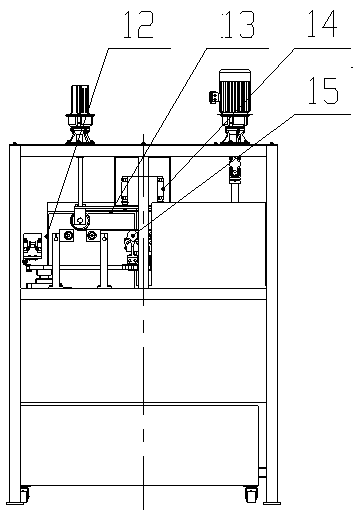

[0016] In conjunction with the accompanying drawings, the specific implementation plan adopted is: a rotary liquid sand blasting machine consists of a body 1, a secondary vertical planetary gear motor 2, a primary vertical planetary gear motor 3, a pulley transmission mechanism 4, Workpiece fixture 5, funnel 6, water tank 7, rotary single-row single-side double-hole chain 8, spray gun 9, through-beam detection switch 10, photoelectric proximity switch 11, timing belt 12, pen cylinder 13, workpiece 14, abrasive fluid The pump 15 and its associated conventional mechanical transmission system, medium power system, pipeline system, and electronic intelligent PLC program control system form a new type of rotary liquid sand blasting machine. When the workpiece 14 is manually placed on the workpiece fixture 5, the machine starts, and the two-stage planetary gear motor 2 drives the rotary single-row single-side double-hole chain 8 to run through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com