Method for continuously producing m-aminoacetanilide hydrochloride

A technology of m-aminoacetanilide hydrochloride and aminoacetanilide hydrochloride, which is applied in the field of synthesis of dye intermediates, can solve the problems of high energy consumption for heating and cooling, low production efficiency, etc., achieve continuous production process and improve production Efficiency, the effect of reducing the amount of refrigerant used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

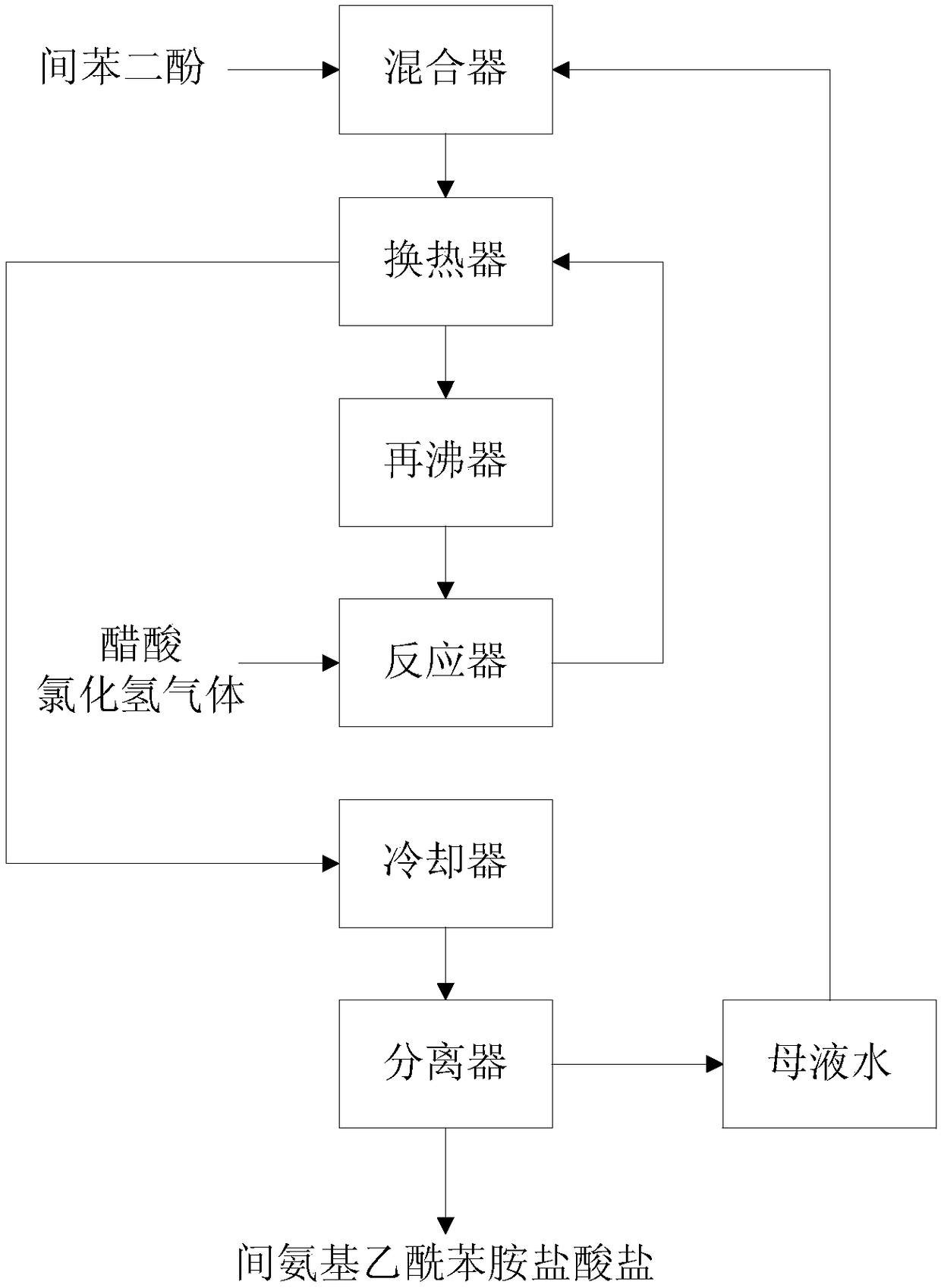

Image

Examples

Embodiment 1

[0030] (1) m-phenylenediamine and mother liquor water are pumped into the mixer by a metering pump at a flow rate of 300kg / hour and 1500kg / hour respectively to obtain mixture A. The temperature of mixture A is 70-73°C. The temperature of the mixture A is raised to 85-88°C, and the temperature of the mixture A is raised to 108-112°C through the reboiler. The mixture A enters the first-stage reactor, and continuously pumps acetic acid into the first-stage reactor. 175kg / hour, continuously feed hydrogen chloride gas into the first-stage reactor, the flow rate is 110kg / hour, the reaction temperature of the first-stage reactor is controlled at 135-138°C, the reaction material overflows to the second-stage reactor, and the first-stage reactor The reaction temperature of the second-stage reactor is controlled at 140-143° C. to generate a mixture B containing m-aminoacetanilide hydrochloride.

[0031] (2) The mixture B exchanges heat with the mixture A through the heat exchanger, and ...

Embodiment 2

[0037] (1) m-phenylenediamine and mother liquor water are pumped into the mixer by a metering pump at a flow rate of 300kg / hour and 1500kg / hour respectively to obtain mixture A. The temperature of mixture A is 70-73°C. The temperature of the mixture A is raised to 85-88°C, and the temperature of the mixture A is raised to 108-112°C through the reboiler. The material of the mixture A enters the first-stage reactor, and continuously pumps acetic acid into the first-stage reactor at a flow rate of 160kg / hour, continuously feed hydrogen chloride gas into the first-stage reactor, the flow rate is 100kg / hour, the reaction temperature of the first-stage reactor is controlled at 132-134°C, and the reaction material overflows to the second-stage reactor; The 2nd stage reactor is pumped into acetic acid, and the flow rate is 20kg / hour, and continuously feeds hydrogen chloride gas into the 2nd stage reactor, and the flow rate is 10kg / hour, and the reaction temperature of the 2nd stage rea...

Embodiment 3

[0044] (1) m-phenylenediamine and mother liquor water are pumped into the mixer by a metering pump at a flow rate of 300kg / hour and 1500kg / hour respectively to obtain mixture A. The temperature of mixture A is 70-73°C. The temperature of the mixture A is raised to 85-88°C, and the temperature of the mixture A is raised to 108-112°C through the reboiler. The material of the mixture A enters the first-stage reactor, and continuously pumps acetic acid into the first-stage reactor at a flow rate of 165kg / hour, continuously feed hydrogen chloride gas into the first-stage reactor, the flow rate is 110kg / hour, the reaction temperature of the first-stage reactor is controlled at 133-135°C, and the reaction material overflows to the second-stage reactor; Acetic acid is pumped into the second-stage reactor, and the flow rate is 10kg / hour. Hydrogen chloride gas is continuously fed into the second-stage reactor, and the flow rate is 5kg / hour. Mixture B of m-aminoacetanilide hydrochloride....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com