A kind of concrete solid brick and preparation method thereof

A solid brick and concrete technology, applied in the field of materials, can solve problems such as single source of raw materials, deterioration of ecological environment, weak support capacity, etc., and achieve the effect of enhancing wear resistance, improving flexural resistance, and improving compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

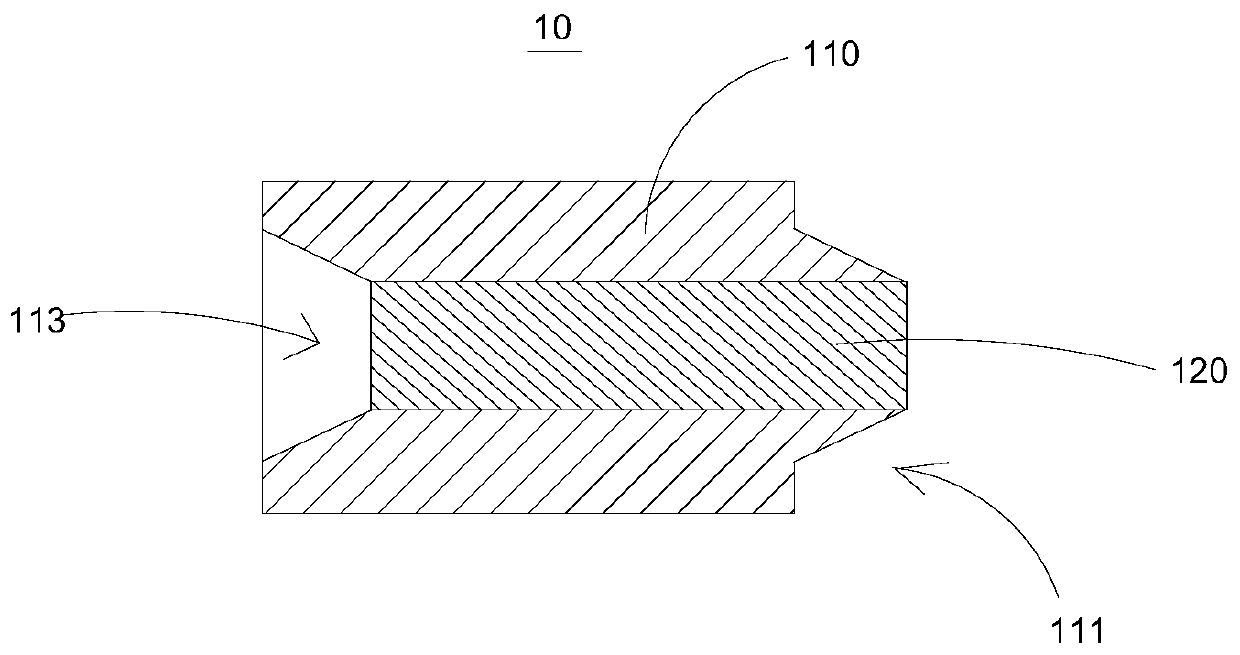

[0035] Please refer to figure 1 , the present embodiment provides a concrete solid brick 10 , which includes a first body 110 and a second body 120 .

[0036] The opposite sides of the first body 110 are respectively provided with a raised portion 111 and a depressed portion 113. The raised portion 111 of a solid brick cooperates with the depressed portion 113 of another solid brick. The cross section of the depressed portion 113 is trapezoidal, and the raised portion The top of 111 communicates with the bottom wall of the recessed part 113 through a mounting hole (not shown), and a second body 120 is poured in the mounting hole, one end of the second body 120 is flush with the bottom wall of the recessed part 113, and the other end is flush with the convex The top wall of the raised portion 111 is flush with each other.

[0037] The concave part 113 is in the shape of a truncated cone, and the circumference of the side of the depression 113 away from the raised part 111 is lar...

Embodiment 2

[0045] The difference between the concrete solid brick provided by the present embodiment and the concrete solid brick provided by Example 1 is only:

[0046] The raw materials of the first body include: 1.2 parts by weight of water, 5 parts by weight of cement, 0.2 parts by weight of silica fume, 0.4 parts by weight of fly ash, 5 parts by weight of sand, 8.5 parts by weight of gravel, 0.1 parts by weight of Parts of water reducer, 0.3 parts by weight of flexible epoxy resin, and 1 part by weight of polymer fiber.

[0047] Wherein, the microsilica powder includes the first microsilica powder and the second microsilica powder, the particle diameter of the first microsilica powder is 15-20um, the particle diameter of the second microsilica powder is 10-15um, the first microsilica powder and the second microsilica powder The mass ratio of the second micro-silica fume is 7:3. Crushed stone includes continuously graded crushed stone with a particle size of 5-20mm.

[0048] The ra...

Embodiment 3

[0051] The difference between the concrete solid brick provided by the present embodiment and the concrete solid brick provided by Example 1 is only:

[0052] The raw materials of the first body include: 1.3 parts by weight of water, 5 parts by weight of cement, 0.25 parts by weight of silica fume, 0.35 parts by weight of fly ash, 5 parts by weight of sand, 8.5 parts by weight of gravel, 0.1 parts by weight of 0.5 parts by weight of water reducer, 0.5 parts by weight of flexible epoxy resin, and 0.5 parts by weight of polymer fibers.

[0053] Wherein, the microsilica powder includes the first microsilica powder and the second microsilica powder, and the particle size of the first microsilica powder is 15-20 mu m, the particle size of the second microsilica is 10-15 mu m, the mass ratio of the first microsilica powder to the second microsilica powder is 6:3.5. Crushed stone includes continuously graded crushed stone with a particle size of 5-20mm.

[0054] The raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com