Industrial waste high-temperature incineration flue gas purification treatment process

A technology for industrial waste and incineration flue gas, which is applied to the treatment of combustion products, incinerators, and reduction of greenhouse gases. It can solve the problems of high exhaust temperature of incineration flue gas, achieve complete incineration, simple process flow, and good purification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

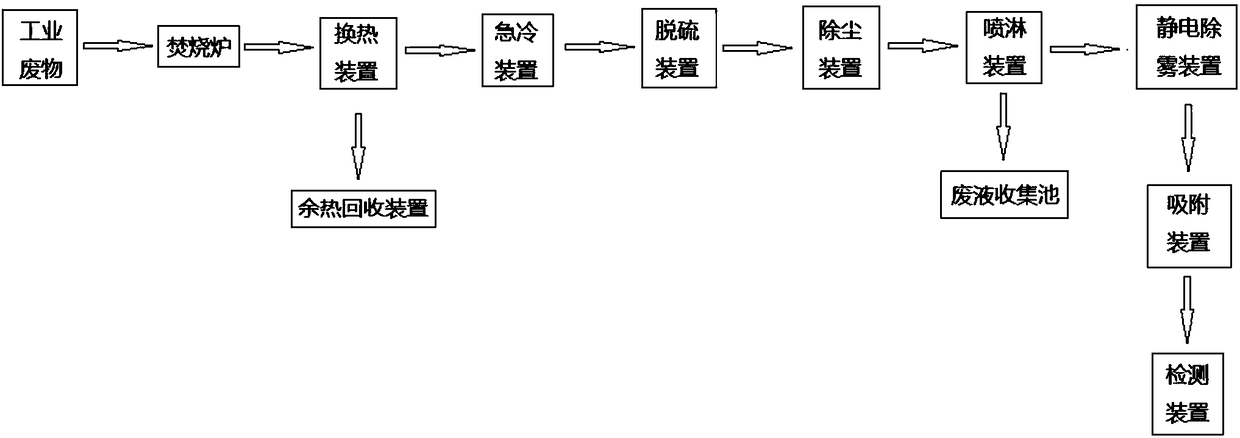

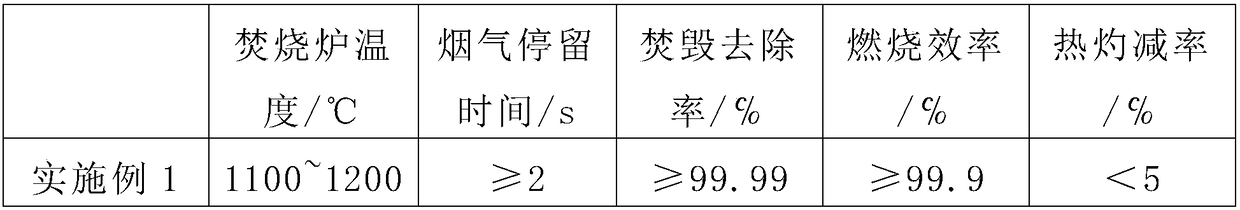

[0048] The specific implementation method is to carry out pretreatment such as sorting, crushing and mixing of industrial waste, put the waste that can be incinerated after pretreatment into the incinerator, control the temperature in the incinerator, burn the waste into flue gas, and first pass through the The heat exchange device and the quenching device reduce the temperature of the flue gas, and recover the waste heat to the waste heat recovery device through the heat exchange device; the flue gas after quenching treatment passes through the deacidification device to remove the acid gas; and then passes through the bag filter to remove Solid soot particles in the flue gas; and then through the spray device, the acid gas and water-soluble dust particles in the flue gas are washed and collected into the waste liquid collection pool; and then removed by the electrostatic demist device The dust particles smaller than 2 μm that cannot be removed by the bag filter and the water m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com