A kind of preparation method of micro-nano granulation

A micro-nano and granulation technology, applied in microsphere preparation, microcapsule preparation, powder suspension granulation and other directions, can solve the problems of unstable embedding effect, complex structure and variability, etc., to improve drying efficiency, preparation Simple process and stable contents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

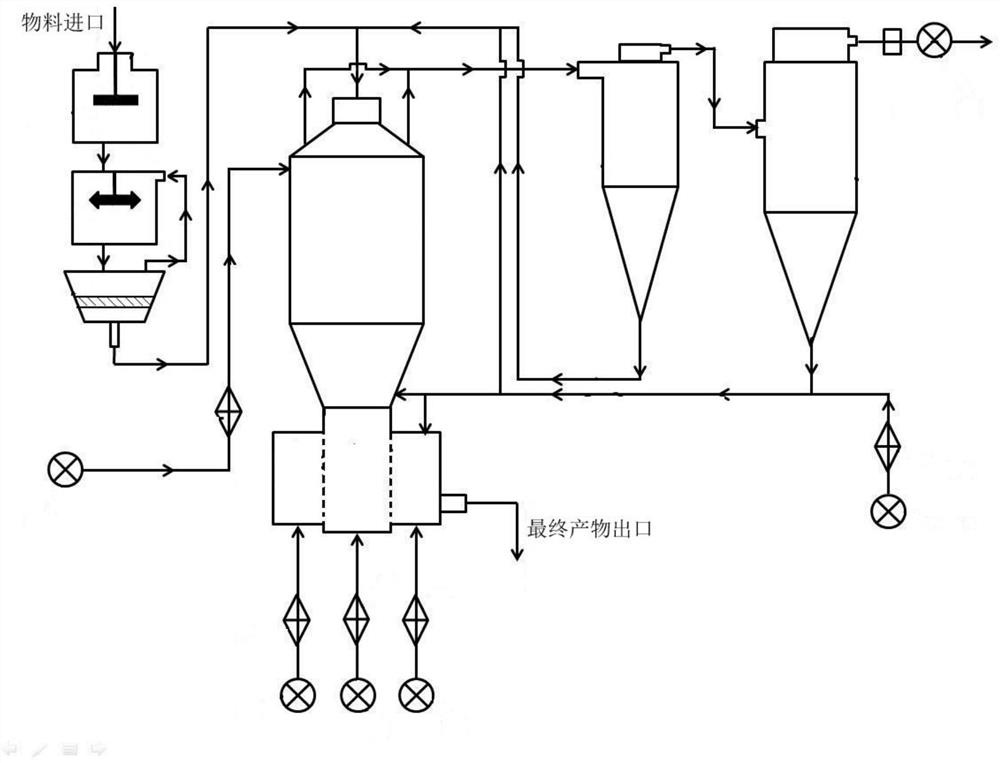

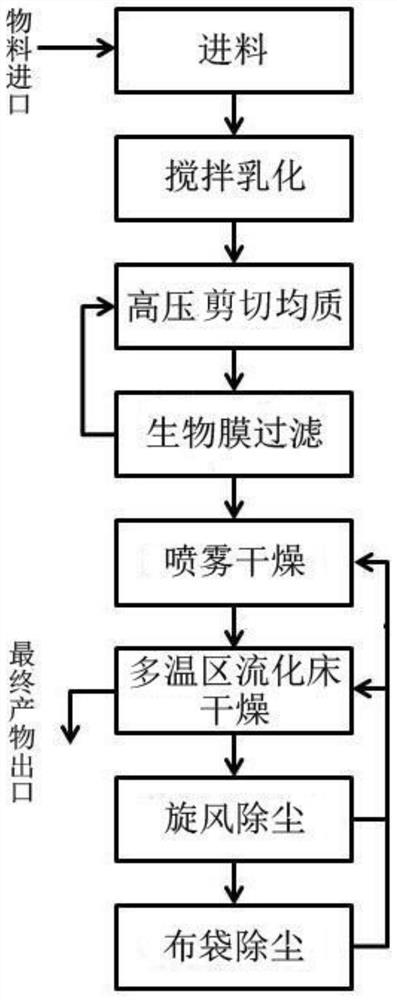

[0023] Such as Figure 1-2 Shown is a specific embodiment of a micro-nano-scale granulation preparation method, the preparation method includes the following steps:

[0024] Step 1): Add the material into the emulsification chamber at a speed of 1kg / h, stir and emulsify at a speed of 30rpm for 20min, then place it under a pressure of 1Mpa, and shear and homogenize for 30min to obtain a material emulsion;

[0025] Step 2): Filter the material emulsion obtained in step 1) through a biofilm with a filter pore size of 1um to obtain a micronano-scale emulsion. If the material emulsion passes through the biofilm filter pore size, enter step 3), otherwise, fail The droplets with the pore size of the biofilm are returned to the pipeline under the pressure of 1Mpa to continue shearing and homogenization, and then filtered through the biofilm with a filter pore size of 1um to obtain a micro-nano emulsion;

[0026] Step 3): Add the micronano emulsion obtained in step 2) into the multi-s...

Embodiment 2

[0031] Such as Figure 1-2 Shown is a specific embodiment of a micro-nano-scale granulation preparation method, the preparation method includes the following steps:

[0032]Step 1): Add the material into the emulsification chamber at a speed of 250kg / h, stir and emulsify at a speed of 1015rpm for 40min, and then place it under a pressure of 10.5Mpa, shear and homogenize for 60min to obtain a material emulsion;

[0033] Step 2): Filter the material emulsion obtained in step 1) through a biofilm with a filter aperture of 250um to obtain a micronano-scale emulsion. If the material emulsion passes through the filter aperture of the biofilm, enter step 3), otherwise, fail The droplets with the pore size of the biofilm flow back through the pipeline to the pressure of 10.5Mpa to continue shearing and homogenization, and then filter through the biofilm with a filter pore size of 250um to obtain a micro-nano emulsion;

[0034] Step 3): Add the micronano-scale emulsion obtained in ste...

Embodiment 3

[0039] Such as Figure 1-2 Shown is a specific embodiment of a micro-nano-scale granulation preparation method, the preparation method includes the following steps:

[0040] Step 1): Add the material into the emulsification chamber at a speed of 500kg / h, stir and emulsify at a speed of 2000rpm for 35min, and then place it under a pressure of 20Mpa, shear and homogenize for 30min to obtain a material emulsion;

[0041] Step 2): Filter the material emulsion obtained in step 1) through a biofilm with a filter aperture of 500um to obtain a micronano-scale emulsion. If the material emulsion passes through the filter aperture of the biofilm, enter step 3), otherwise, fail The droplets with the pore size of the biofilm flow back through the pipeline to the pressure of 20Mpa to continue shearing and homogenization, and then filter through the biofilm with a filter pore size of 500um to obtain a micro-nano emulsion;

[0042] Step 3): Add the micronano emulsion obtained in step 2) into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com