Method for preparing catalysis material for synthesizing tetraphenylporphyrin

A technology of tetraphenylporphyrin and catalytic material, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of small effective catalytic area and reduced yield , easy residue and other problems, to achieve uniform and controllable pH, reduce waste of raw materials, and good chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

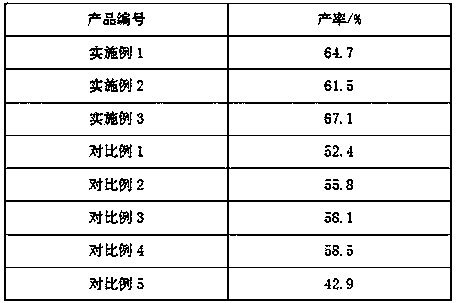

Examples

Embodiment 1

[0016] Step 1. Preparation of the composition

[0017] In the reaction kettle, add 1000g of N,N-dimethylformamide, 60g of p-phenylazoamine-4-sulfonic acid, 27.5g of 3,3'-dicarboxydiphenyl disulfide, 1-propylsulfonic acid Acid-3-methylimidazolium trifluoromethanesulfonate 0.05 g, (S)-2-(diphenyl(trimethylsilyloxy)methyl)pyrrolidine 0.05 g, and mix well at room temperature.

[0018] Step 2. Preparation of Catalyst

[0019] Add 1000g of styrene-based macroporous weakly acidic cation exchange resin, 200g of the composition prepared in step 1, 50g of iron tetrafluoroborate, 1150g of N,N-dimethylformamide into the reaction kettle, heat up to 87°C, and keep it warm for 13h , after the completion, the product is taken out, washed with water, and dried to obtain a catalytic material for synthesizing tetraphenylporphyrin.

Embodiment 2

[0021] Step 1. Preparation of the composition

[0022] In the reaction kettle, add 1000g of N,N-dimethylformamide, 30g of p-phenylazoamine-4-sulfonic acid, 5g of 3,3'-dicarboxydiphenyl disulfide, 1-propylsulfonic acid -0.01 g of 3-methylimidazolium trifluoromethanesulfonate, and 0.01 g of (S)-2-(diphenyl(trimethylsilyloxy)methyl)pyrrolidine, and mix well at room temperature.

[0023] Step 2. Preparation of Catalyst

[0024] Add 1000g of styrene-based macroporous weakly acidic cation exchange resin, 100g of the composition prepared in step 1, 20g of iron tetrafluoroborate, 800g of N,N-dimethylformamide into the reaction kettle, heat up to 80°C, and keep it warm for 6h , after the completion, the product is taken out, washed with water, and dried to obtain a catalytic material for synthesizing tetraphenylporphyrin.

Embodiment 3

[0026] Step 1. Preparation of the composition

[0027] In the reaction kettle, add 1000g of N,N-dimethylformamide, 90g of p-phenylazoamine-4-sulfonic acid, 50g of 3,3'-dicarboxydiphenyl disulfide, 1-propylsulfonic acid -0.1 g of 3-methylimidazolium trifluoromethanesulfonate, and 0.1 g of (S)-2-(diphenyl(trimethylsilyloxy)methyl)pyrrolidine, and mix well at room temperature.

[0028] Step 2. Preparation of Catalyst

[0029] Add 1000g of styrene-based macroporous weakly acidic cation exchange resin, 300g of the composition prepared in step 1, 80g of ferric tetrafluoroborate, 1500g of N,N-dimethylformamide into the reaction kettle, raise the temperature to 95°C, and keep it warm for 20h , after the completion, the product is taken out, washed with water, and dried to obtain a catalytic material for synthesizing tetraphenylporphyrin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com