A kind of snpbbisb series low temperature reinforced solder and preparation method thereof

A bi-sb, solder technology, applied in the field of low-temperature brazing solder and its preparation, can solve the problems of low melting point of alloy, reliability of PCB deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

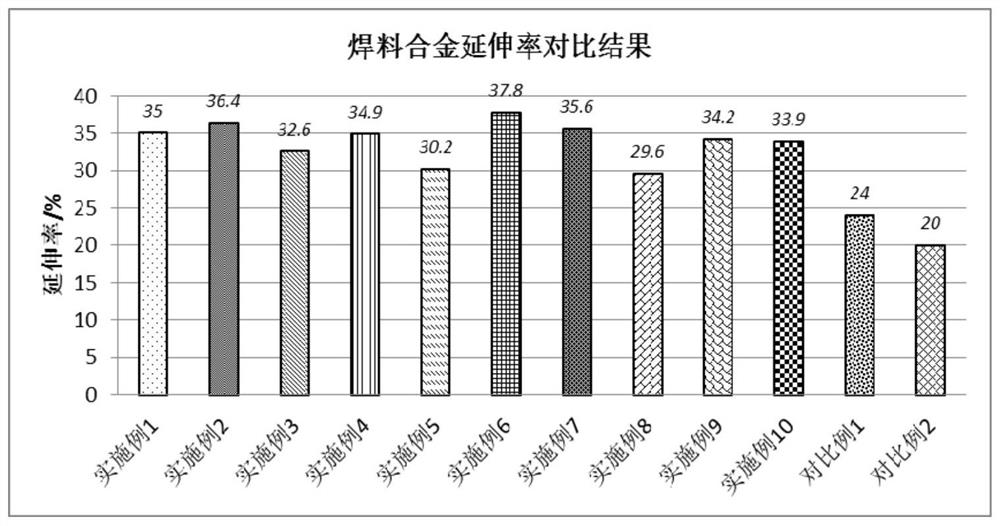

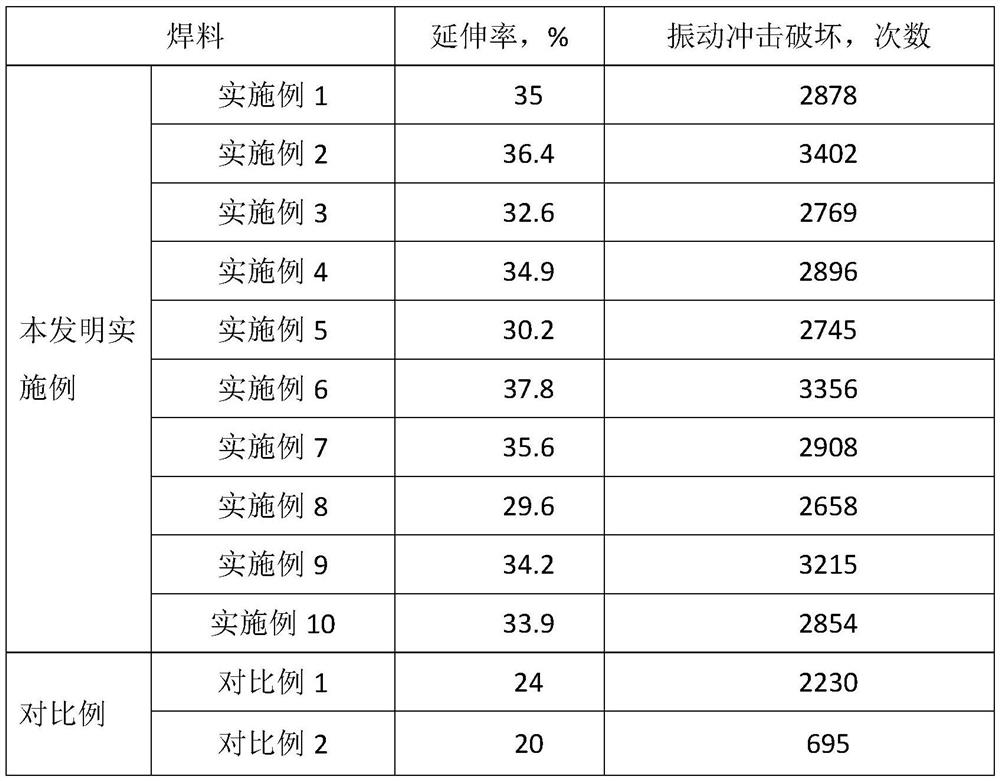

Embodiment 1

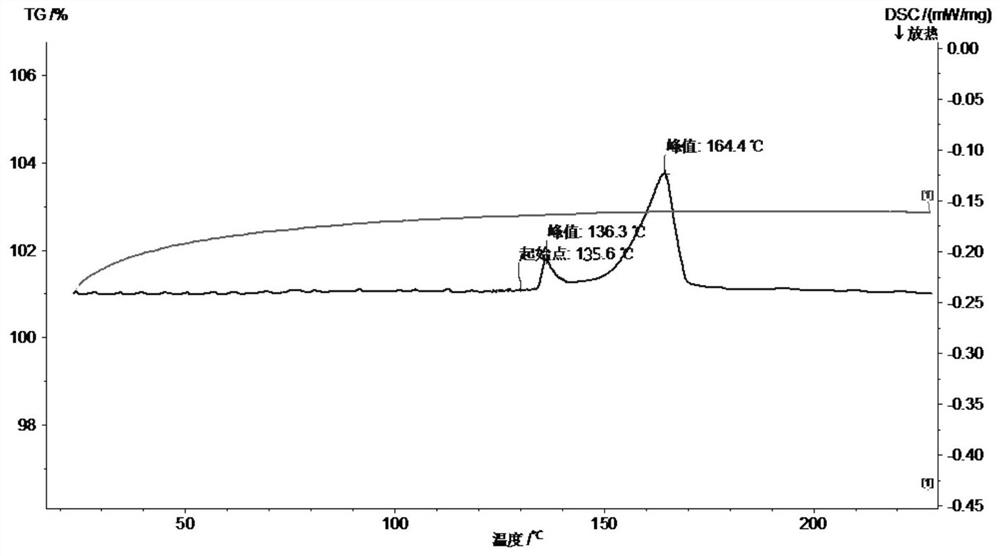

[0044] A SnPbBiSb series low-temperature enhanced solder alloy, in weight percentage, the solder alloy contains: Pb 39%, Bi 13%, Sb 2.5%, the rest is Sn, and the melting point of the solder alloy is 129-163.4°C. The method for preparing the solder alloy comprises the following steps:

[0045] 1) Add metal Bi and Sb with a purity of 99.99wt.% into the vacuum melting furnace at an alloy ratio of 80:20 by weight, and vacuumize to 1×10 -1 Pa, filled with nitrogen; heat the alloy to 650-700 ° C to melt, and at the same time, add electromagnetic stirring to make the alloy composition uniform, and then vacuum cast to prepare the Bi-Sb20 master alloy;

[0046] 2) The prepared Bi-Sb master alloy and metals Sn and Pb are melted in a melting furnace according to the alloy ratio. Cover the surface of the alloy with an anti-oxidation solvent. The anti-oxidation solvent can be selected from rosin or KCl-LiCl molten salt. Heat the alloy to 250°C and keep it warm for 10 minutes to remove the...

Embodiment 2

[0048] A SnPbBiSb series low temperature reinforced solder alloy, in weight percentage, the solder alloy contains: Pb 46%, Bi 18.1%, Sb 1.24%, the rest is Sn, the melting point of the solder alloy is 129.5-162.8°C. The method for preparing the solder alloy is the same as that in Example 1 except that the alloy ratio is different.

Embodiment 3

[0050] A kind of SnPbBiSb series low-temperature strengthened solder alloy, the solder alloy contains: Pb 35.6%, Bi 8.1%, Sb 0.001%, Ce 0.003%, Al 0.03%, Ag 0.5%, and the rest is Sn by weight percentage. The melting point of the alloy is 126.8-165.5°C. The method for preparing the solder alloy comprises the following steps:

[0051] 1) Add metal Bi and Sb with a purity of 99.99wt.% into the vacuum melting furnace at an alloy ratio of 80:20 by weight, and vacuumize to 1×10 -2 Pa, filled with nitrogen, heated to 650-700 ° C to melt, and at the same time, electromagnetically stirred to make the alloy composition uniform, and then vacuum cast to prepare a Bi-Sb20 master alloy;

[0052] 2) Add metals Sn and Ce, Sn and Al, Sn and Ag with a purity of 99.99wt.% into the vacuum melting furnace according to a certain alloy ratio, and vacuumize to 1×10 -2 Pa, after being filled with nitrogen; the alloys were heated to 690-780°C, 650-700°C, and 350-450°C to melt, and electromagnetic sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com