Method for preparing hydrophobic transparent vanadium dioxide thermochromic smart glass by electrospinning technology

A technology of vanadium dioxide and smart glass, applied in the field of materials, can solve problems such as the opacity of electrospun composite films, achieve the effects of improving oxidation resistance, broadening applications, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

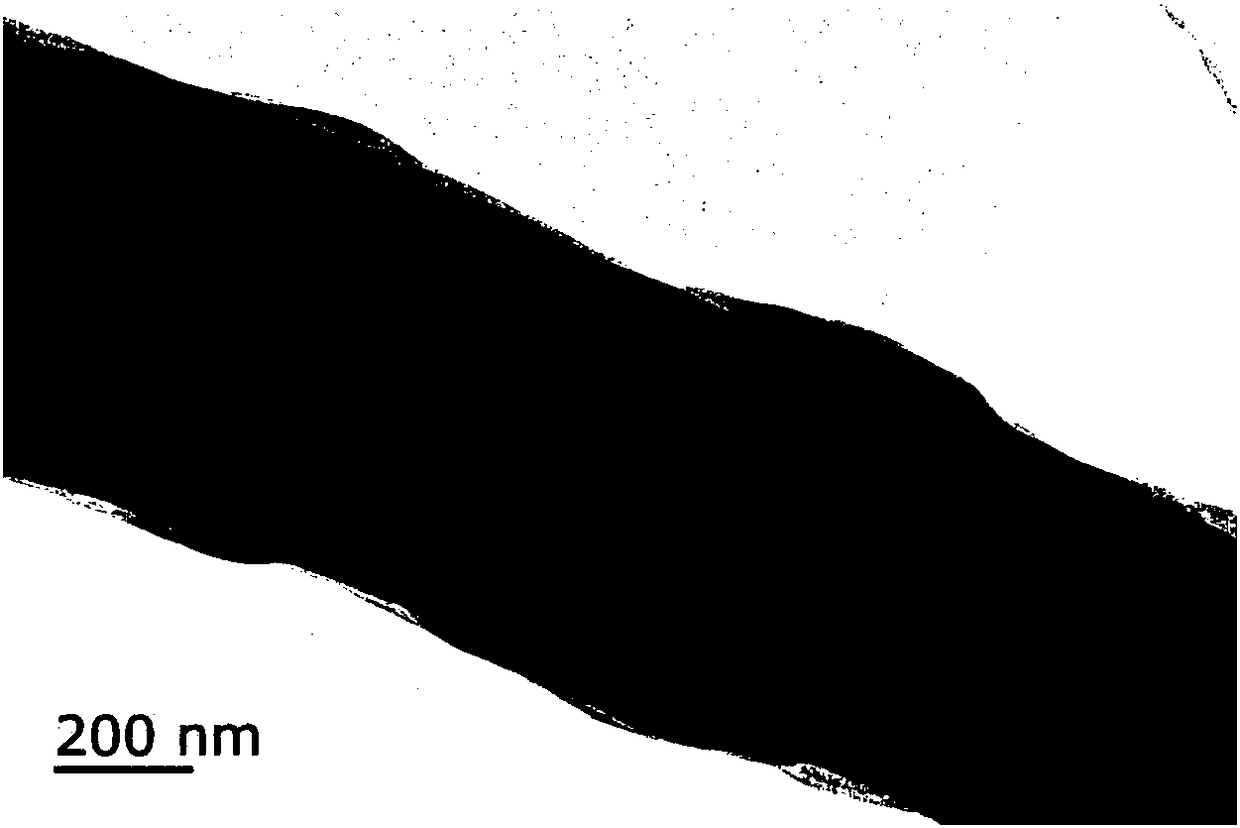

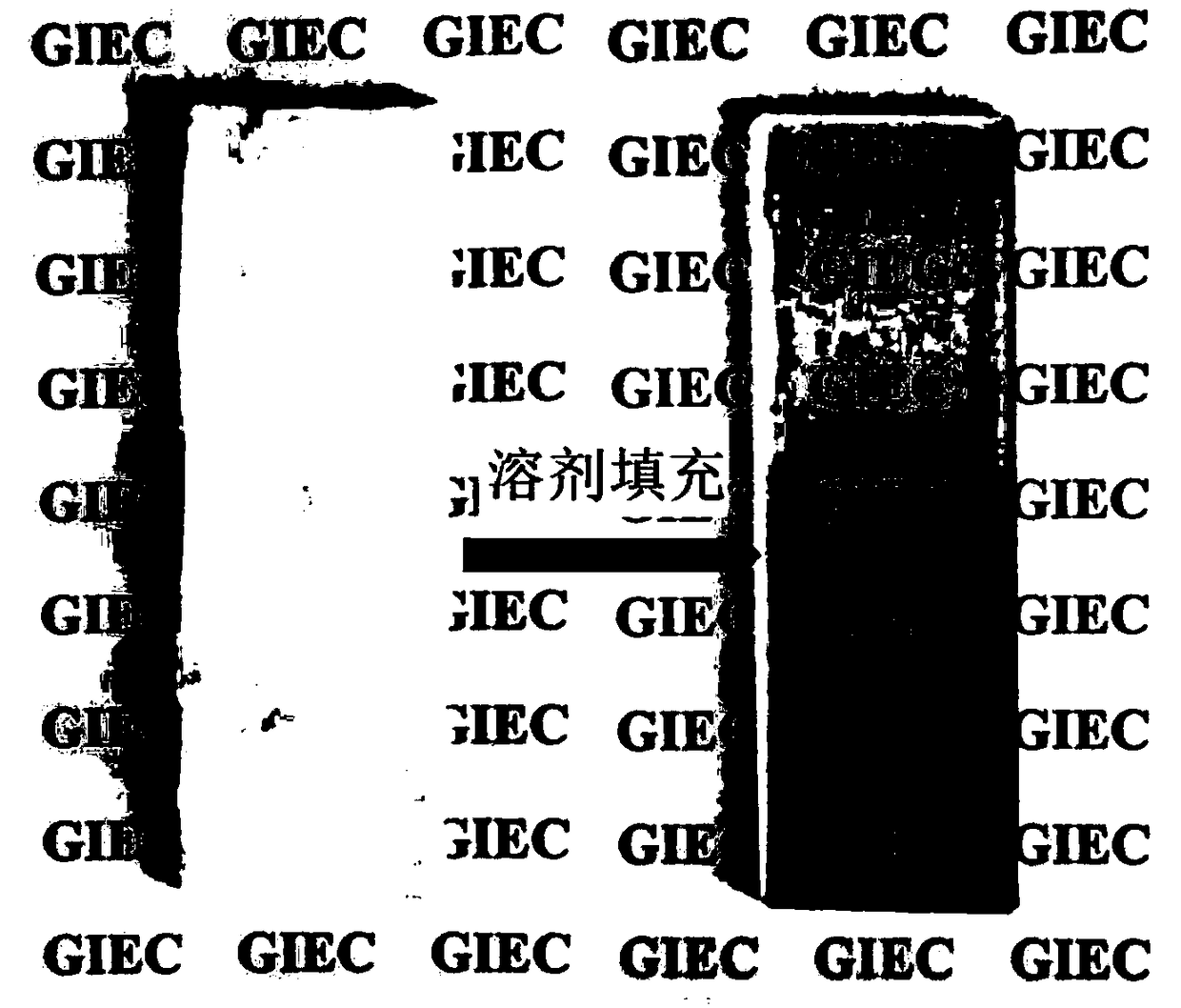

[0032] 0.5wt% VO 2 Added to DMF, sonicated for 1h. After stirring at room temperature for 2 h, 20 wt% PMMA was added. Stirring was continued for 6 h to obtain a uniform gray-black electrospinning precursor solution. Adjust the parameters of the electrospinning process: the voltage is 15kV; the receiving distance is 15cm; the solution pushing speed is 0.5ml / h, the glass is used as the receiving substrate, the solution is electrospun, and the sample is received after 72h to obtain the electrospun composite fiber membrane. The diameter of the composite fiber membrane fiber is 500 nm. Its SEM picture is as follows figure 1 shown. Fill the obtained composite fiber membrane with DMF, and then treat it in an oven at 40°C for 6 hours to obtain a VO with a transmittance of 93%. 2 Thermochromatic smart glass. Comparison of the state before and after the electrospun composite fiber membrane is filled with solvent image 3 shown. It can be seen from the figure that it is opaque be...

Embodiment 2

[0036] 2wt%VO 2 Added to DMF, sonicated for 2h. After stirring at room temperature for 2 h, 20 wt% PMMA was added. Stirring was continued for 6 h to obtain a uniform gray-black electrospinning precursor solution. Adjust the parameters of the electrospinning process: the voltage is 20kV; the receiving distance is 15cm; the solution pushing speed is 5ml / h, the solution is electrospun with glass as the receiving substrate, and the sample receiving is completed after 6h. Fill the obtained composite fiber membrane with DMF, and then treat it in an oven at 60°C for 24 hours to obtain a VO with a transmittance of 75%. 2 Thermochromatic smart glass.

Embodiment 3

[0038] 10wt%VO 2 Added to DMF, sonicated for 6h. After stirring at room temperature for 2 h, 20 wt% PMMA was added. Stirring was continued for 6 h to obtain a uniform gray-black electrospinning precursor solution. Adjust the parameters of the electrospinning process: the voltage is 20kV; the receiving distance is 15cm; the solution pushing speed is 1ml / h, and the glass is used as the receiving substrate for electrospinning, and the sample receiving is completed after 6h. Fill the obtained composite fiber membrane with DMF, and then treat it in an oven at 60°C for 12 hours to obtain a VO with a transmittance of 50%. 2 Thermochromatic smart glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com