Glufosinate ammonium preparation method

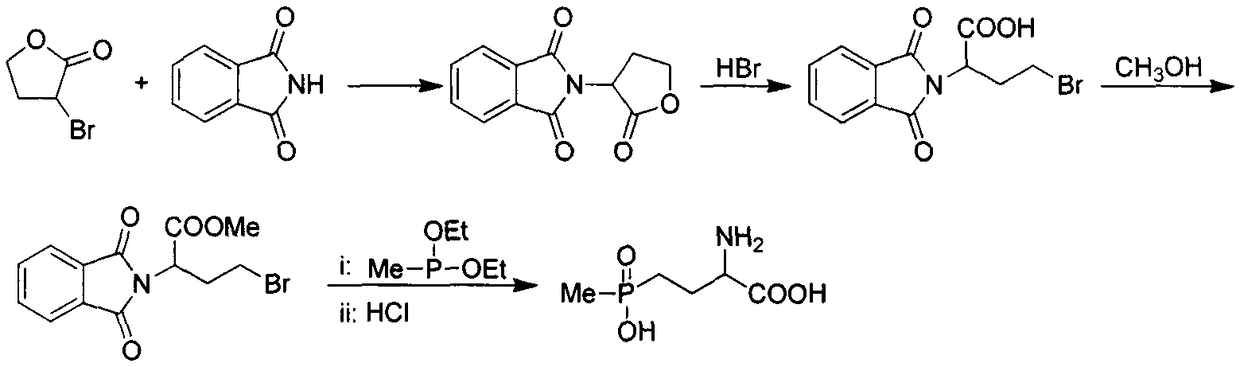

A technology of glufosinate-ammonium and methyl phosphonite is applied in the new preparation field of herbicide glufosinate-ammonium, which can solve the problems of expensive phthalimide, poor atom economy and low yield, etc. Atomic economy, easy operation, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

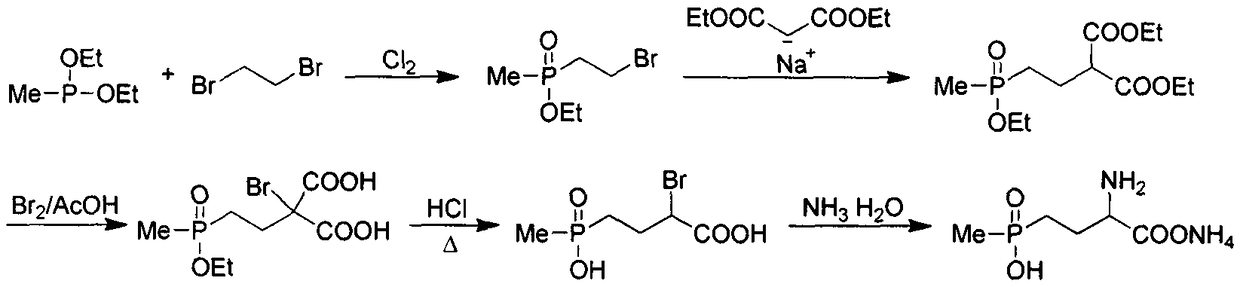

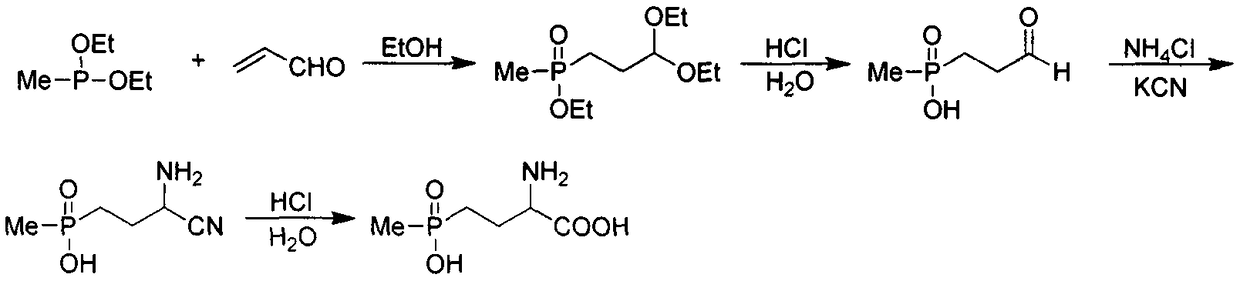

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Add α-bromo-γ-butyrolactone 2 (16.5g, 0.1mmol) and sodium nitrite (13.8g, 0.2mmol) into a 100mL reaction flask filled with DMF (20mL), and stir at room temperature for 30min The response is complete. After the completion, 50 mL of ethyl acetate was added for dilution, and then washed with water (80 mL×3) to remove DMF, and the organic phase was concentrated to obtain 10.2 g of α-nitro-γ-butyrolactone 3, which was directly used in the next reaction, with a yield of 78%.

[0030] Step 2: Add compound 3 (39.3g, 0.3mmol), 45% hydrobromic acid (75mL), and methanol (150mL) to a 500mL reaction flask sequentially, heat up to 75°C and reflux for 4h, then cool down to room temperature, and stir overnight. After the reaction was completed, the solvent was removed under reduced pressure, and the obtained crude product was dissolved in ethyl acetate (150 mL), washed successively with saturated sodium bicarbonate solution and saturated brine (150 mL), dried over anhydrous mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com