Granular colored asphalt and preparation method thereof

A colored asphalt and granular technology, applied in the field of granular colored asphalt and its preparation, can solve the problems of high cost, troublesome, engineering dispersion, etc., and achieve the effects of improving high temperature performance, convenient use and formula optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of the above-mentioned granular colored asphalt, which includes adding C5 petroleum resin, C9 petroleum resin, SBS, and polyurethane into a high-speed mixer and stirring for 5 minutes, and then adding aromatic oil and stirring for 10 minutes to make the aromatic oil front The added materials are fully absorbed, and finally polyethylene wax, phosphate ester, SBR, and pigments are added, and stirred for 10 minutes, so that the powdery materials such as pigments are adsorbed on the surface of the granular materials, and mixed evenly; the mixed materials are added to the twin-screw extrusion In the feeding hopper of the machine, the temperature of each section of the screw is set to 140℃~170℃, and the granular colored asphalt can be obtained through the processes of extrusion, drawing, cooling, pelletizing, and drying.

[0025] In specific embodiments, the method for producing colored asphalt mixture using the granular co...

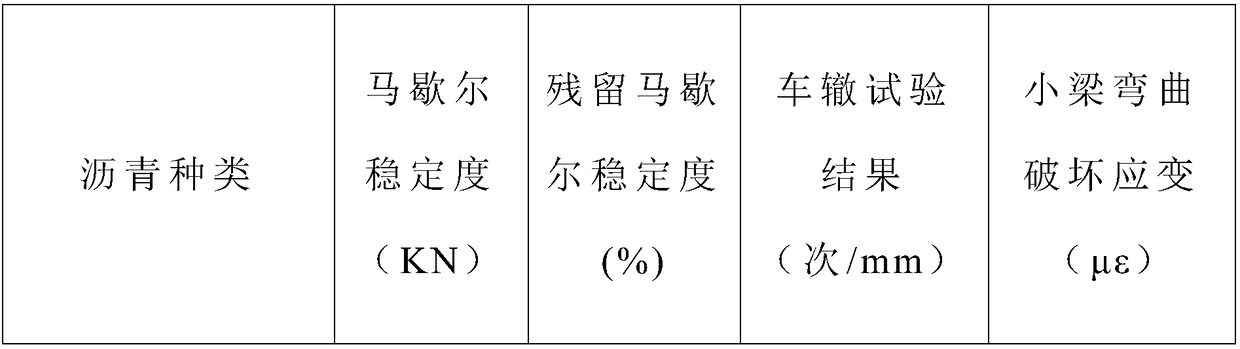

Embodiment 1

[0032] Take 10 parts of C5 petroleum resin, 40 parts of C9 petroleum resin, 50 parts of aromatic oil, 12 parts of SBS, 2 parts of polyethylene wax, 4 parts of SBR, 5 parts of polyurethane, 40 parts of iron red, and 3 parts of phosphate. Add the above-mentioned C5 petroleum resin, C9 petroleum resin, SBS, and polyurethane into a high-speed mixer and stir for 5 minutes, then add aromatic oil and stir for 10 minutes to fully absorb the materials added in front of the aromatic oil, and finally add polyethylene wax, Phosphate, SBR, iron red, stir for 10 minutes, so that the powdery materials such as pigments are adsorbed on the surface of the granular materials, and the mixture is evenly mixed.

[0033] Add the uniformly mixed materials into the feed hopper of the twin-screw extruder. The temperature of the screw is set to 140°C, 145°C, 150°C, 155°C, 160°C, 160°C, and 155°C from the feeding section to the die head. Extrusion, drawing, cooling, pelletizing, drying and other processes c...

Embodiment 2

[0036] Take 15 parts of C5 petroleum resin, 35 parts of C9 petroleum resin, 55 parts of aromatic oil, 15 parts of SBS, 4 parts of polyethylene wax, 5 parts of SBR, 4 parts of polyurethane, 45 parts of chrome green, and 4 parts of phosphate. Add the above-mentioned C5 petroleum resin, C9 petroleum resin, SBS, and polyurethane into a high-speed mixer and stir for 5 minutes, then add aromatic oil and stir for 10 minutes to fully absorb the materials added in front of the aromatic oil, and finally add polyethylene wax, Phosphate, SBR, chrome green, stir for 10 minutes, so that the powdery materials such as pigments are absorbed on the surface of the granular materials, and the mixture is evenly mixed.

[0037] Add the uniformly mixed materials into the feed hopper of the twin-screw extruder. The temperature of the screw is set to 150°C, 155°C, 160°C, 165°C, 170°C, 165°C, and 155°C from the feeding section to the die head. Extrusion, stranding, cooling, pelletizing, drying and other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com