A preparation method of ta2 cold-rolled titanium strip for low-strength, easy-to-form welded pipes

A low-strength, forming welding technology, applied in the field of titanium material processing, can solve the problems of prolonging the service life of welded pipe forming roller molds, low production speed of welded pipe production lines, and easy to produce wear marks on the surface of titanium welded pipes, etc., to achieve the reduction of mold design and manufacturing capacity requirements , good production adaptability, good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

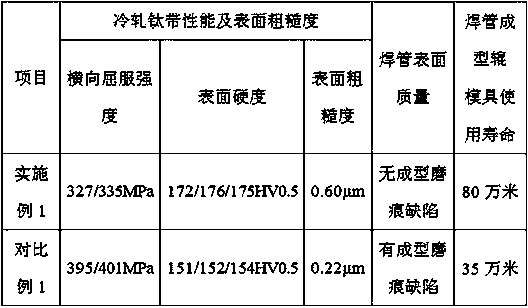

Embodiment 1

[0025] Embodiment 1: using sponge titanium and TiO 2 Carry out batching, after batching O, Fe, C, N impurity element content mass percent is respectively 0.125%, 0.018%, 0.017%, 0.01%, [O] 当 =[O]%+0.5*[Fe]%+ 0.7*[C]%+2.5*[N]%=0.125%+0.5*0.018%+0.7* 0.017%+2.5*0.01%=0.1709%, and after Smelting, forging, hot rolling, cold rolling, annealing and other processes to obtain a 1.0mm annealed TA2 pure titanium cold-rolled titanium strip blank; use a cold rolling mill to cold-roll the titanium strip blank to a target thickness of 0.404mm, The cold-rolled deformation is 59.6%; the degreasing unit is used to clean and dry the cold-rolled titanium strip; the argon-protected continuous annealing line is used to perform Kaiping annealing on the cold-rolled titanium strip, the annealing temperature is 720 degrees Celsius, and the holding time is 4 minutes; Acid + nitric acid + water" mixed acid solution pickled the cold-rolled titanium strip after continuous annealing, and dried it; then us...

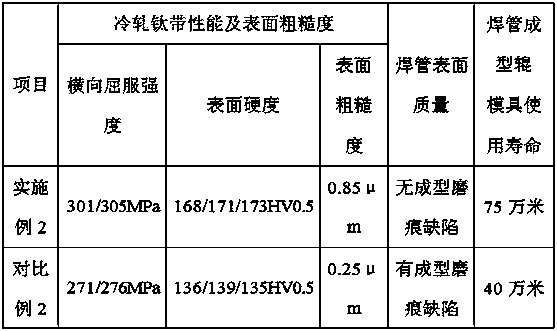

Embodiment 2

[0030] Embodiment 2: Using sponge titanium and TiO 2 Carry out batching, O, Fe, C, N impurity element content mass percent after batching is respectively 0.085%, 0.031%, 0.012%, 0.006%, [O] 当=[O]%+0.5*[Fe]% +0.7*[C]%+2.5*[N]%=0.085%+0.5*0.031%+0.7*0.012%+2.5*0.006%=0.1239%, and after Smelting, forging, hot rolling, cold rolling, annealing and other processes to obtain a 2.0mm annealed TA2 pure titanium cold-rolled titanium strip blank; use a cold rolling mill to cold-roll the titanium strip blank to a target thickness of 0.709 mm, The cold-rolled deformation is 64.6%; the degreasing unit is used to clean and dry the cold-rolled titanium strip; the argon-protected continuous annealing line is used to perform Kaiping annealing on the cold-rolled titanium strip, the annealing temperature is 680 degrees Celsius, and the holding time is 3 minutes; Acid + nitric acid + water" mixed acid solution pickled the cold-rolled titanium strip after continuous annealing, and dried it; then u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com