Dispersing leveling agent for polyester fibers and preparation method thereof

A polyester fiber and leveling agent technology, which is applied in the field of fabric printing and dyeing, can solve the problems of prone to color blooms, uneven dyeing color of color spots, and poor dyeing vats, so as to improve dyeing vats, increase coloring speed, and disperse Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

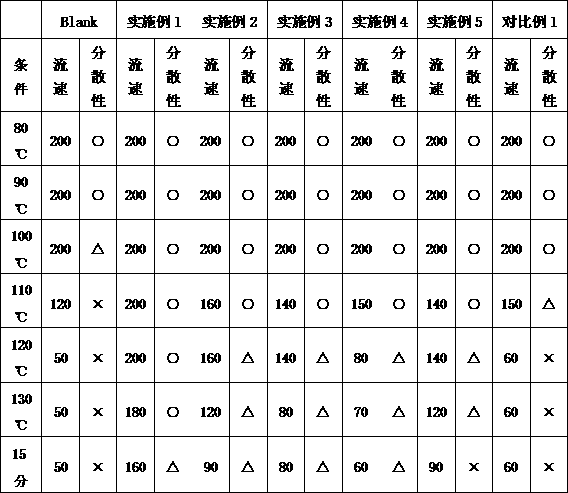

Examples

Embodiment 1

[0018] A disperse leveling agent for polyester fibers, comprising the following raw materials in parts by weight: 500 parts of water, 100 parts of styrene phenol polyoxyethylene ether, 100 parts of ammonium lauryl polyoxyethylene ether sulfate and N-alkyl o 350 parts of phthalimide.

[0019] The preparation method of a disperse leveling agent for polyester fibers, adding styrene phenol polyoxyethylene ether, lauryl polyoxyethylene ether ammonium sulfate and N-alkyl phthalimide in sequence to react In the kettle, heat to 80°C, stir well, add water, stir evenly, and cool to room temperature to obtain the finished product.

[0020] A method of using the disperse leveling agent for polyester fibers: add 1-3g / L to the dyeing working solution.

[0021] Water can be used as a solvent to disperse the other raw materials, which can make the disperse leveling agent have better stability under normal conditions, and can be added to the dyeing working solution relatively easily.

[0022...

Embodiment 2

[0026] A disperse leveling agent for polyester fibers, comprising the following raw materials in parts by weight: 600 parts of isopropyl alcohol, 150 parts of castor oil polyoxyethylene ether, 50 parts of styrene phenol polyoxyethylene sulfate ester salt and benzoic acid benzene Base 150 parts.

[0027] The preparation method of a disperse leveling agent for polyester fibers, adding castor oil polyoxyethylene ether, styrene phenol polyoxyethylene sulfate ester salt and benzoic acid phenyl into the reaction kettle in sequence, heating to 80°C After fully stirring, add isopropanol, stir evenly, and cool to room temperature to obtain the finished product.

[0028] A method of using the disperse leveling agent for polyester fibers: add 1-3g / L to the dyeing working solution.

Embodiment 3

[0030] A disperse leveling agent for polyester fiber, comprising the following raw materials in parts by weight: 580 parts of sorbitol, 120 parts of polyethylene glycol fatty acid ester, 80 parts of sodium lignosulfonate and 200 parts of dipropylene glycol benzoate share.

[0031] The preparation method of a disperse leveling agent used for polyester fiber comprises adding polyethylene glycol fatty acid ester, sodium lignin sulfonate and dipropylene glycol benzoate into the reaction kettle in sequence, heating to 80°C, After fully stirring, add sorbitol, stir evenly, and cool to room temperature to obtain the finished product.

[0032] A method of using the disperse leveling agent for polyester fibers: add 1-3g / L to the dyeing working solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com