50MW grade ultra-high-temperature back pressure steam turbine recovery type steam exhaust adjustment bypass system and control method thereof

A bypass system, 50MW technology, used in mechanical equipment, engine components, machines/engines, etc., can solve problems such as waste of working fluid, longer start-up time, unit safety issues, etc., to avoid frequent actions and reduce working fluids Loss, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

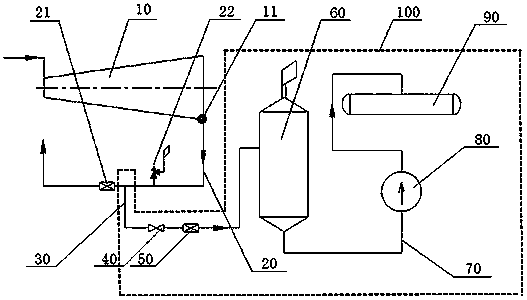

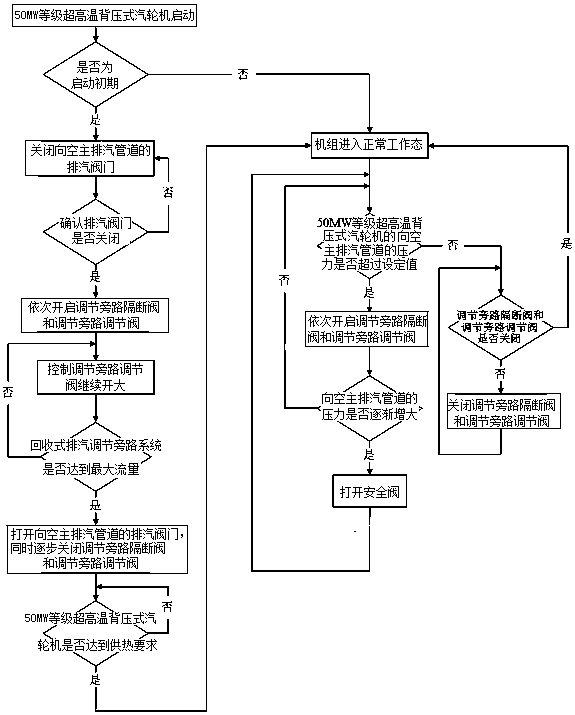

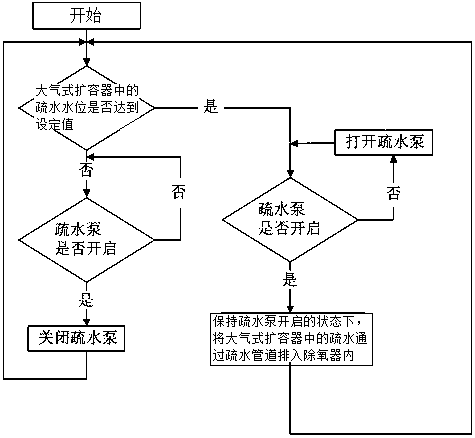

[0051] refer to figure 1 As shown, a 50MW grade ultra-high temperature back pressure recovery type exhaust steam adjustment bypass system includes a 50MW grade ultra high temperature back pressure steam turbine 10 and a main air exhaust pipe 20, and one end of the air main exhaust pipe 20 is connected to a 50MW The exhaust steam heat supply pipe interface 11 of the grade ultra-high temperature back pressure steam turbine 10 is connected, and an exhaust valve 21 and a safety valve 22 are provided. There is also a recovery regulating bypass system 100, which includes exhaust steam regulating bypass pipe 30, regulating bypass regulating valve 50, atmospheric expansion vessel 60, drain pump 80 and deaerator 90, One end of the exhaust steam regulation bypass pipe 30 is connected to the air main exhaust pipe 20, and the other end is connected to the atmospheric expansion vessel 60. The recovery regulating bypass system 100 does not exhaust steam to the air. The road regulating valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com