A treatment method for radioactive waste resin

A technology of radioactive waste resin and treatment method, applied in radioactive purification, nuclear engineering and other directions, can solve the problems of high cost, high current intensity, high concentration of silver nitrate and nitric acid, poor treatment effect, etc., to achieve the safety of degradation products and facilitate the final disposal. , the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

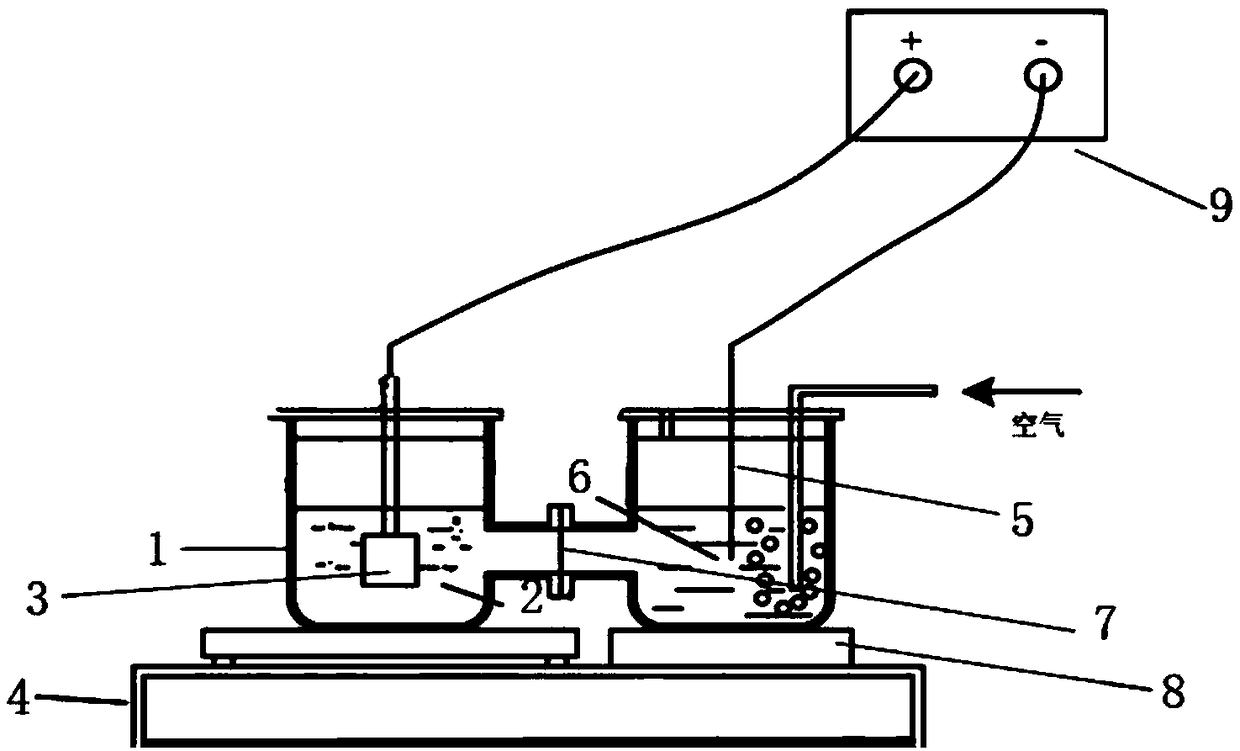

[0026] like figure 1 As shown, the cathode and anode chambers of the electrolytic cell 1 are separated by Nafion membrane 7, a platinum electrode is inserted in the anode chamber as the anode electrode 3, and HNO is added 3 and Ag + 120mL of the mixed solution, in which HNO 3 Concentration is 8mol / L, Ag + The concentration is 0.2mol / L, put 2g of macroporous strongly acidic ion exchange resin into it, connect the anode to the positive pole of the power supply 9, place the anode chamber 2 on the magnetic stirrer 4 to ensure that the resin is evenly dispersed; in the cathode chamber 6 Put the gasket 8 down, add 120mL of 8mol / L HNO to the cathode chamber 3 The solution is continuously fed with air, inserted into the platinum electrode as the cathode 5, connected to the negative pole of the power supply, and continuously aerated, using a DC regulated power supply to provide a stable current, and the current density is controlled at 250mA / cm 2 , the temperature was 25°C, and the...

Embodiment 2

[0028] Separate the cathode and anode chambers of the electrolytic cell with Nafion membrane, insert a platinum electrode in the anode chamber as the anode electrode, and add HNO 3 and Ag +120mL of the mixed solution, in which HNO 3 Concentration is 8mol / L, Ag + The concentration is 0.2mol / L, put 2g of macroporous strongly acidic ion exchange resin into it, connect the anode to the positive pole of the power supply, place the anode chamber on a magnetic stirrer to ensure that the resin is evenly dispersed; put a pad under the cathode chamber sheet, add 120mL of 8mol / L HNO to the cathode chamber 3 The solution is continuously fed with air, a platinum electrode is inserted as a cathode, connected to the negative pole of the power supply, and continuously aerated, and a DC regulated power supply is used to provide a stable current, and the current density is controlled at 250mA / cm 2 , the temperature was 25°C, and the reaction time was 6 hours. The remaining resin in the anode...

Embodiment 3

[0030] Separate the cathode and anode chambers of the electrolytic cell with Nafion membrane, insert a platinum electrode in the anode chamber as the anode electrode, and add HNO 3 and Ag + 140mL of the mixed solution, in which HNO 3 Concentration is 7mol / L, Ag + The concentration is 0.2mol / L, put 1.5g of macroporous strongly acidic ion exchange resin into it, connect the anode to the positive pole of the power supply, place the anode chamber on a magnetic stirrer; add 140mL of 7mol / L ion exchange resin to the cathode chamber HNO 3 The solution is continuously fed with air, a platinum electrode is inserted as a cathode, connected to the negative electrode of the power supply, and continuously aerated, and a DC regulated power supply is used to provide a stable current, and the current density is controlled at 200mA / cm 2 , the temperature was 25°C, and after 2.5 hours of reaction, the remaining resin in the anode chamber was washed and dried, and the resin degradation rate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com