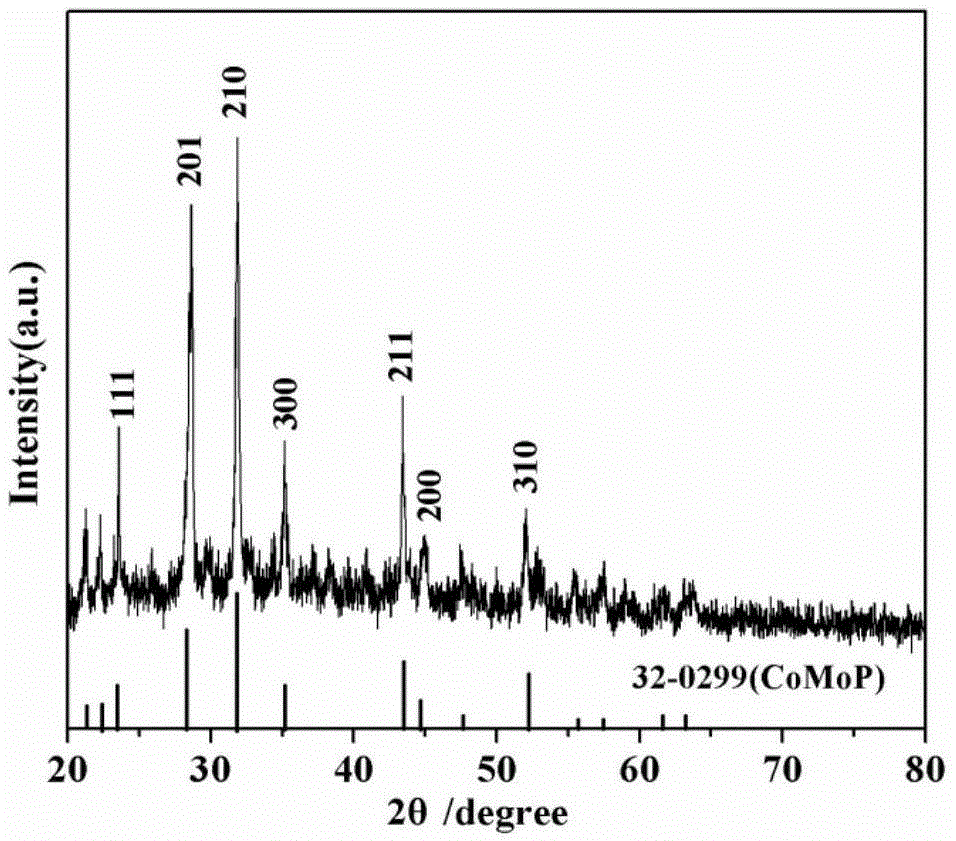

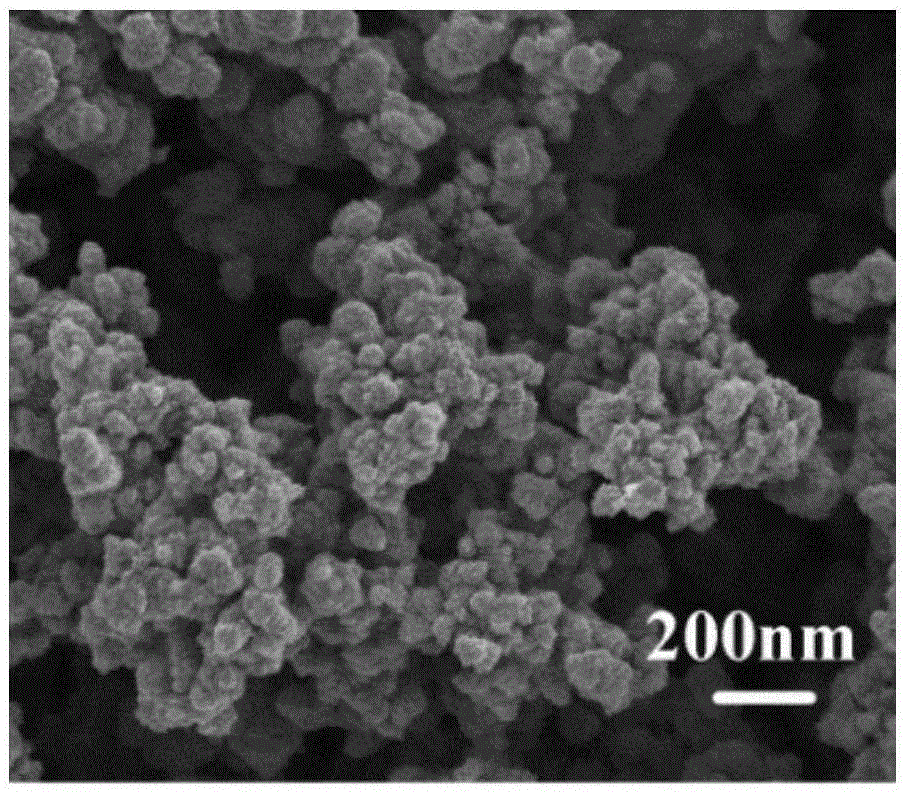

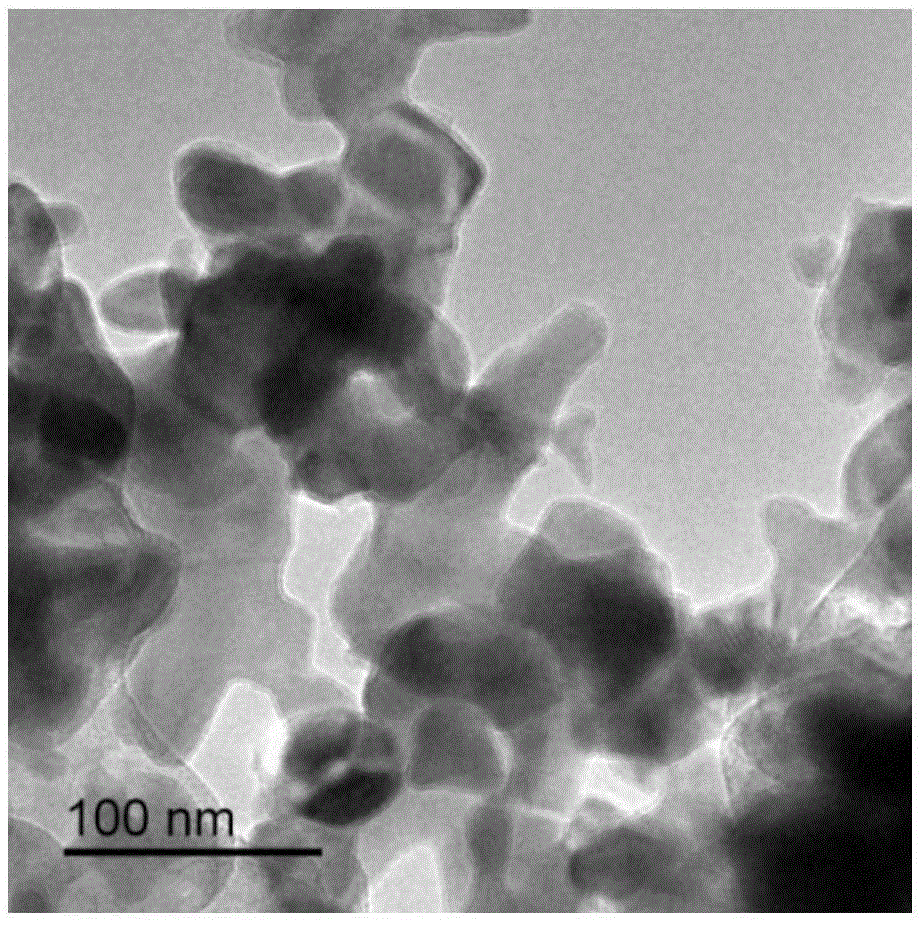

Method for preparing cobalt-molybdenum phosphide nano material of hexagonal phase structure

A technology of cobalt molybdenum phosphide and nanomaterials, applied in chemical instruments and methods, phosphides, phosphorus compounds, etc., can solve the problems of product uniformity and low repeatability, and achieve high photocatalytic performance and high experimental repeatability. , the effect of easily controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of cobalt molybdenum phosphide nanomaterial with hexagonal phase structure, comprising the following steps:

[0029] 1) Add 34mL ethylene glycol to 50mL polytetrafluoroethylene liner, then add 0.4365g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and 0.3707g ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 0), then the polytetrafluoroethylene liner is placed on a magnetic stirrer and stirred until the solution is uniform;

[0030] 2) Add 1mL of acetic acid to the PTFE liner and stir until completely dissolved;

[0031] 3) Add 0.1865g of elemental white phosphorus to the polytetrafluoroethylene lining, then seal the polytetrafluoroethylene lining into the reaction kettle, and heat it from room temperature to 200°C under airtight conditions for 18 hours;

[0032] 4) After the reaction is completed, the resulting black precipitate is transferred to a centrifuge tube, washed successively with benzene, water, and absolute ethanol and ...

Embodiment 2

[0034] Embodiment 2: change embodiment 1 step 2) acetic acid into formic acid, other conditions are constant, hexagonal phase structure cobalt molybdenum phosphide (CoMoP) is 88% and 82% to the degradation rate of material sangrin T, basic fuchsin .

Embodiment 3

[0035] Embodiment 3: change embodiment 1 step 2) acetic acid into propionic acid, other conditions are constant, hexagonal phase structure cobalt molybdenum phosphide (CoMoP) is 89% and 80% to the degradation rate of material sangrin T, basic fuchsin %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com