C/ZnO/BiOI ternary composite photocatalytic material

A photocatalytic material and ternary composite technology, applied in the field of C/ZnO/BiOI ternary composite photocatalytic materials, can solve the problems of long preparation time, expensive raw materials, complicated and cumbersome process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

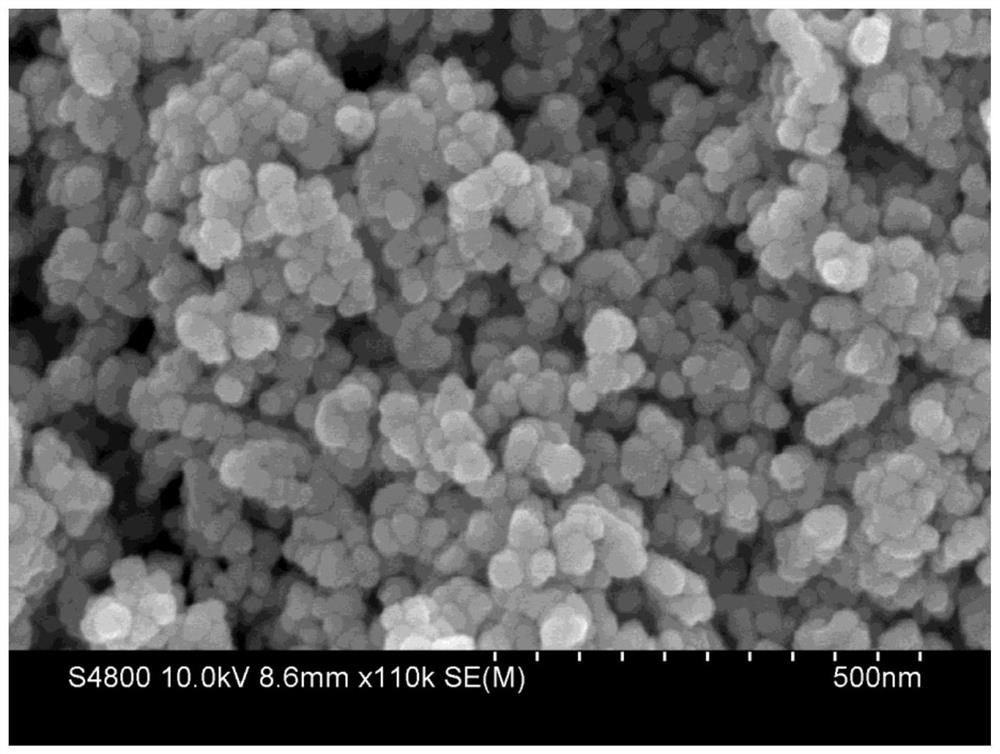

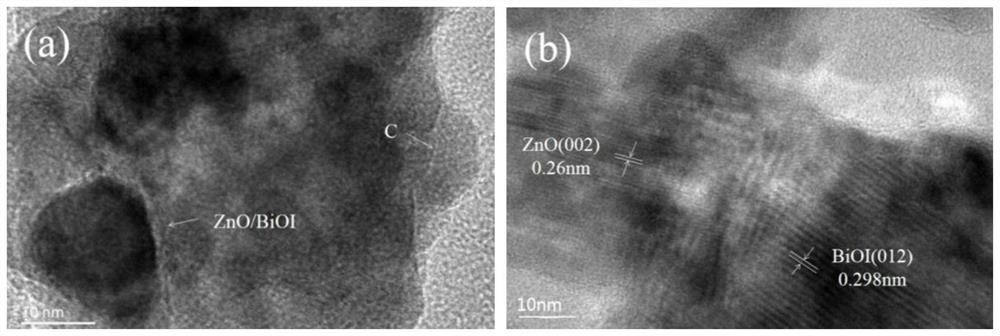

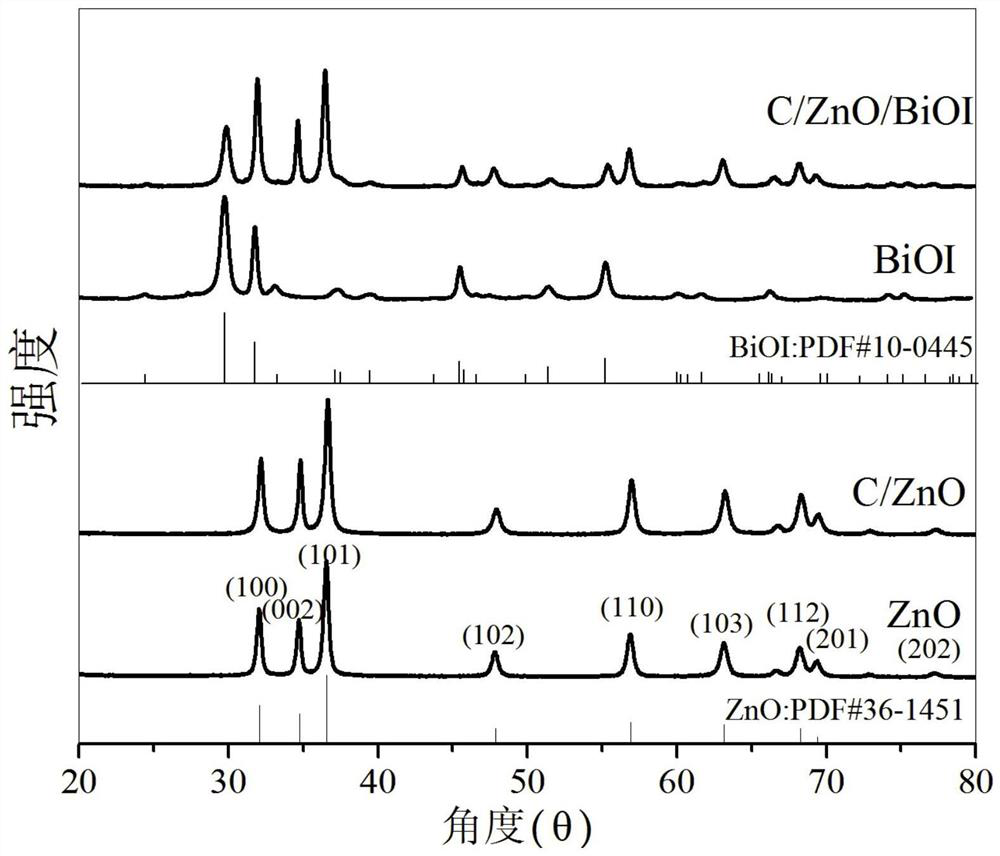

[0043] Specific embodiment one: the preparation method of a kind of C / ZnO / BiOI ternary composite photocatalytic material in this embodiment is carried out according to the following steps:

[0044] 1. Weigh 1.317g of zinc acetate and dissolve it in 30ml of deionized water, add 1g of glucose, and stir for 10min. Add 1 g of polyethylene glycol, stir well, add 0.2M NaOH (60 ml) to adjust the pH to 12, and stir for 30 min. Transfer to a 150ml reactor and react at 180°C for 3h. After cooling to room temperature, wash with 100ml deionized water and 100ml ethanol, and centrifuge. Dry at 70°C. Calcined at 300°C for 3h. Obtain ZnO / C photocatalytic material.

[0045] 2. Add 20mL ethylene glycol, 0.97gBi(NO 3 ) 3 ·5H 2 O and 0.332g KI, stirred and dissolved to form a homogeneous solution; under vigorous stirring, slowly drop 20mL distilled water, and continue to stir for 1h, then filter under reduced pressure; use distilled water to wash the precipitate 2 to 3 times, and dry at 60°...

specific Embodiment approach 2

[0049] 1. Weigh 1.317g of zinc acetate and dissolve it in 30ml of deionized water, add 1.025g of glucose, and stir for 10min. Add 2 g of polyethylene glycol, stir evenly, add 0.2M NaOH (80 ml) to adjust the pH to 12, and stir for 30 min. Transfer to a 150ml reactor and react at 160°C for 2.5h. After cooling to room temperature, wash with 100ml deionized water and 100ml ethanol, and centrifuge. Dry at 70°C. Calcined at 350°C for 3.5h. Obtain C / ZnO photocatalytic material.

[0050] 2. Add 20mL ethylene glycol, 0.97gBi(NO 3 ) 3 ·5H 2 O and 0.332g KI, stirred and dissolved to form a homogeneous solution; under vigorous stirring, slowly drop 20mL distilled water, and continue to stir for 1h, then filter under reduced pressure; use distilled water to wash the precipitate 2 to 3 times, and dry at 60°C to obtain BiOI photocatalytic Material.

[0051]3. Weigh 0.8g C / ZnO and dissolve in 20ml deionized water, dissolve 0.27g BiOI in 20ml deionized water, stir vigorously for 40min, ...

specific Embodiment approach 3

[0054] 1. Weigh 1.317g of zinc acetate and dissolve it in 30ml of deionized water, add 1.025g of glucose, and stir for 10min. Add 1 g of polyethylene glycol, stir well, add 0.2M NaOH (80 ml) to adjust the pH to 12, and stir for 30 min. Transfer to a 150ml reactor and react at 170°C for 2.5h. After cooling to room temperature, wash with 100ml deionized water and 100ml ethanol, and centrifuge. Dry at 70°C. Calcined at 250°C for 3.5h. Obtain C / ZnO photocatalytic material.

[0055] 2. Add 20mL ethylene glycol, 0.97gBi(NO 3 ) 3 ·5H 2 O and 0.332g KI, stirred and dissolved to form a homogeneous solution; under vigorous stirring, slowly drop 20mL distilled water, and continue to stir for 1h, then filter under reduced pressure; use distilled water to wash the precipitate 2 to 3 times, and dry at 60°C to obtain BiOI photocatalytic Material.

[0056] 3. Weigh 0.8g C / ZnO and dissolve in 20ml deionized water, dissolve 0.12g BiOI in 20ml deionized water, stir vigorously for 40min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com