Deep-color super-hydrophobic infrared-reflection thermal insulation coating and preparation method thereof

A heat-insulating coating and super-hydrophobic technology, applied in the field of coatings, can solve the problems of difficulty in meeting the requirements of the colorfulness of the coating, the anti-infrared effect is not durable, and the stain resistance is poor, and achieves good self-cleaning effect, construction and environmental friendliness, Improve the appearance of beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

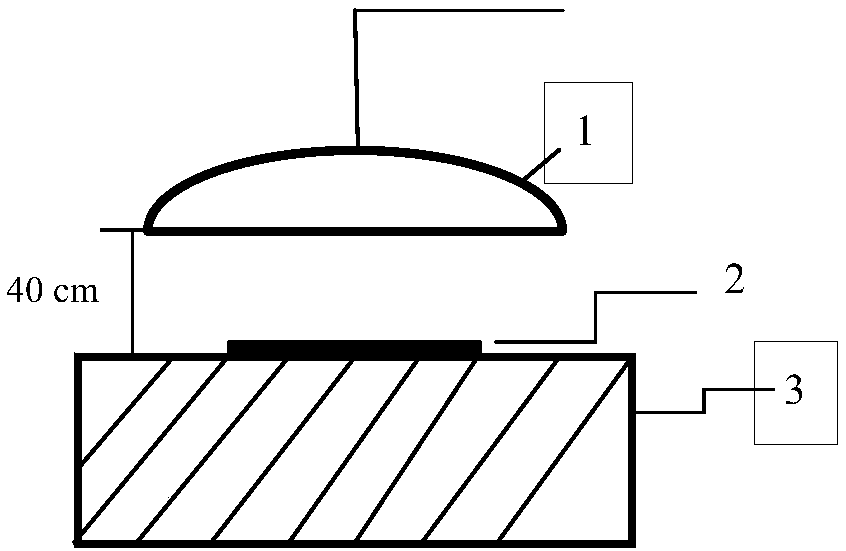

Image

Examples

Embodiment 1

[0035] To 20g ethanol, add 0.4g nano-SiO 2 (Zhejiang Wanjing New Material Co., Ltd., SP-30, average particle size 30nm, the same below, commonly known as white carbon black) and 50g of water, add 1g of γ-aminopropyltriethoxysilane (KH-550, Shanghai Aladdin Biochemical Technology Co., Ltd., the same below), 0.8g heptadecafluorodecyltriethoxysilane (FAS-17, Quanzhou Sikang New Material Co., Ltd., the same below) and 10 drops of dilute hydrochloric acid (3.7wt% Aqueous hydrochloric acid solution, the same below) is used to make the solution weakly acidic (pH ~ 4, the same below), stir for 2 hours to hydrolyze the siloxane, and prepare nano-SiO 2 / Composite sol of fluorosilica sol.

[0036] Add 0.6g AB-EP-51 type epoxy resin and 0.48g AB-HGA type curing agent (Zhejiang Anbang New Material Co., Ltd., the same below) to the above-mentioned composite sol, continue to stir for 15min, and then add 7g "cooler" "Black pigment (30C941, U.S. Schett Pigment Company, particle diameter 1 μm...

Embodiment 2

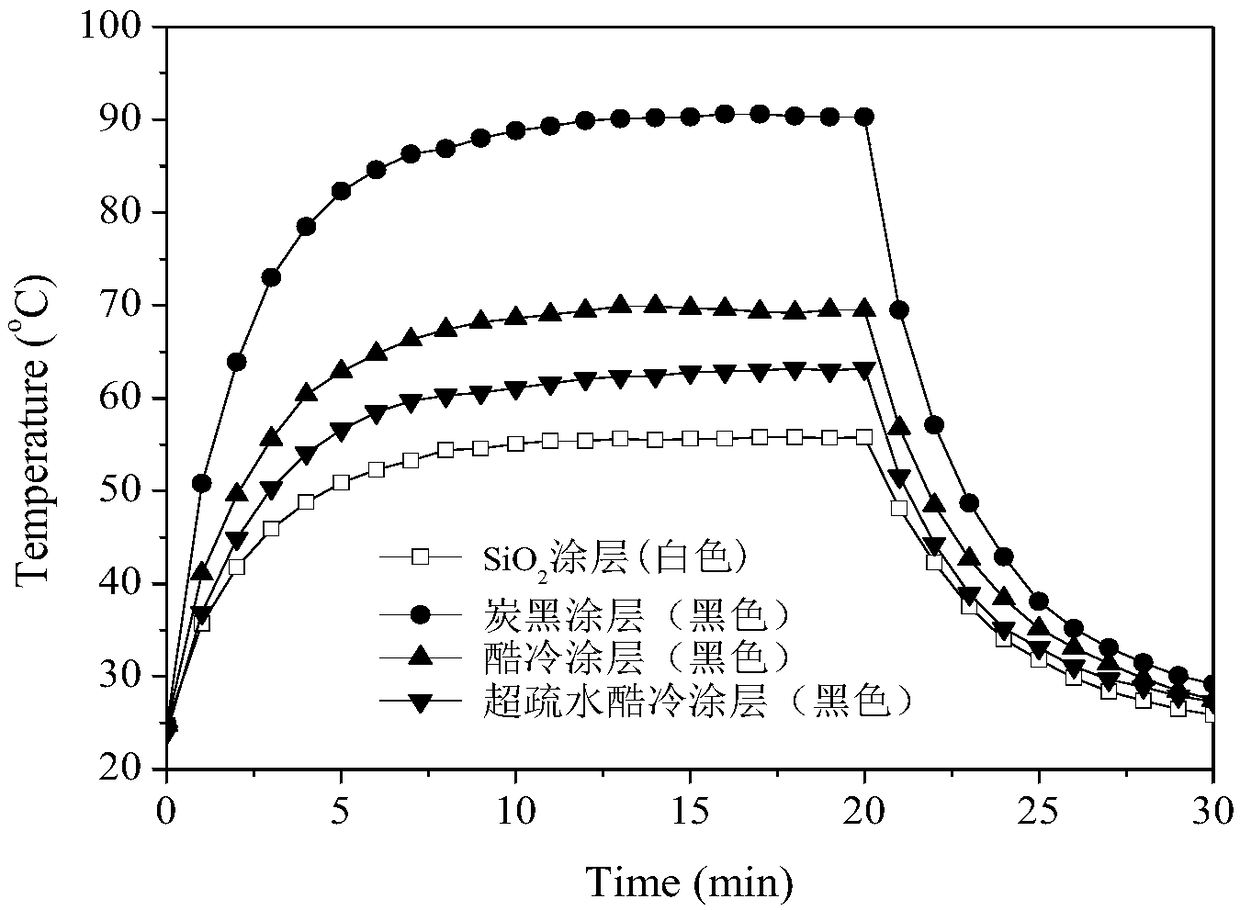

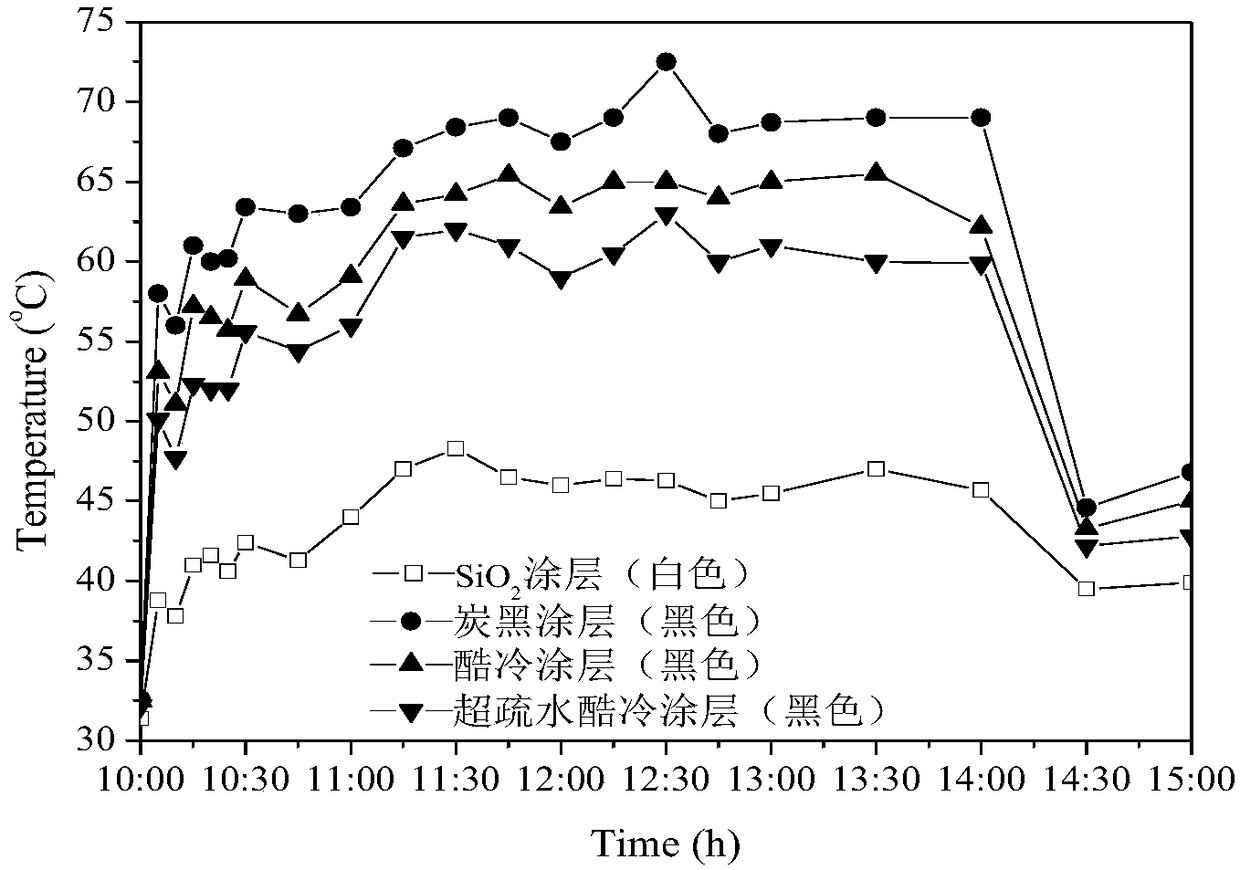

[0040] Others are the same as in Example 1, except that the amount of the "cool" black pigment is changed to 3.5 g (the solid content of the cool pigment in the paint is ~4.5wt%). The infrared reflectance of the resulting coating is shown in Figure 4 . The surface of the super-hydrophobic cool coating exhibits typical super-hydrophobic properties. The mechanical properties are shown in Table 1.

Embodiment 3

[0042] Others are the same as in Example 1, changing the amount of "cool" black pigment to 14g (solid content of cool pigment in coating ~ 16wt%). The infrared reflectance of the resulting coating is shown in Figure 4 . The surface of the super-hydrophobic cool coating exhibits typical super-hydrophobic properties. The mechanical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com