Transfer film waterborne mold releasing agent and preparation method thereof

A water-based release and transfer film technology, applied in the direction of reproduction/marking method, coating, printing, etc., can solve the problems of safe production, environment, personal health hazards, etc., and achieve the benefits of production efficiency, moderate curing temperature, and improved safety. The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

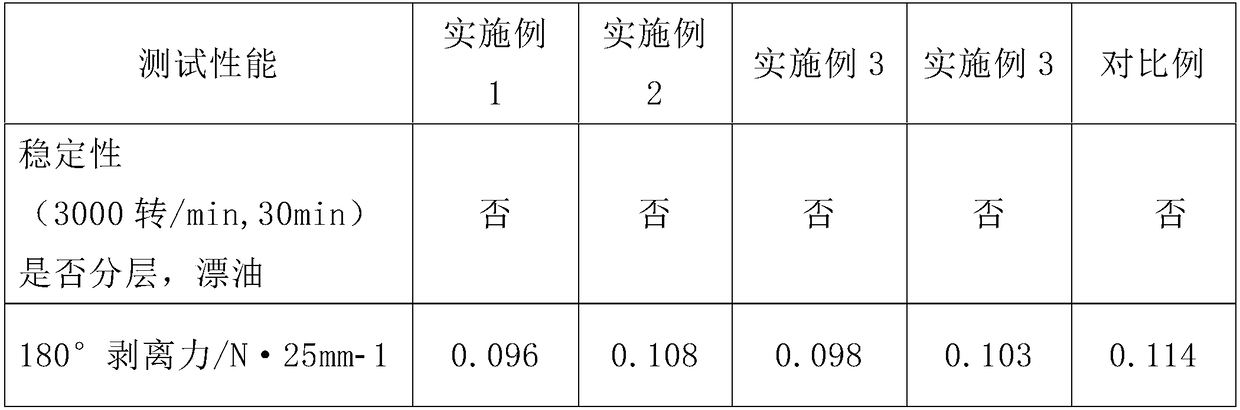

Embodiment 1

[0039] 21.2 grams of methyl hydrogen silicone oil (hydrogen content 0.7%, viscosity 120cS), 100 grams of vinyl silicone oil (vinyl content 2%, viscosity 4000cS), 2.2 grams of Span 40, 1.8 grams of Tween 80, 3 grams of fatty alcohol Add polyoxyethylene ether AEO-9, 5 grams of isomeric tridecyl alcohol polyoxyethylene ether 1303, into the reaction kettle, stir at a stirring speed of 700 rpm for 20 minutes, mix well, add 40 grams of deionized water twice in a row, After each addition of water, use a high-shear emulsifier to cut for 20 minutes at a speed of 4000 rpm, and finally add 89.8 grams of deionized water, stir for 10 minutes, add 0.2 grams of glacial acetic acid to adjust the pH value to 6, and obtain A Components, solid content 40%.

[0040] 1 gram of chloroplatinic acid, 100 grams of vinyl silicone oil (vinyl content 1%, viscosity 2000cS), then add 2.8 grams of Span 40, 2.2 grams of Tween 80, 1.9 grams of fatty alcohol polyoxyethylene ether AEO-9, 3.1 grams Add isotride...

Embodiment 2

[0043] 9.2 grams of methyl hydrogen silicone oil (hydrogen content 0.9%, viscosity 100cS), 112 grams of vinyl silicone oil (vinyl content 0.8%, viscosity 1500cS), 3.3 grams of Span 40, 2.7 grams of Tween 80, 8 grams of isomer Add tridecyl alcohol polyoxyethylene ether 1305 into the reaction kettle, stir at a stirring speed of 700 rpm for 20 minutes, mix well, add 40 grams of deionized water twice in a row, and use high-shear emulsification after each addition of water The machine was cut at a speed of 4000 rpm for 20 minutes, and finally 89.8 grams of deionized water was added, stirred for 10 minutes, and 0.2 grams of glacial acetic acid was added to adjust the pH value to 6 to obtain component A with a solid content of 40%.

[0044] 1 gram of chloroplatinic acid, 100 grams of vinyl silicone oil (vinyl content 2%, viscosity 4000cS), then add 2.8 grams of Span 40, 2.2 grams of Tween 80, 7 grams of isomeric tridecyl polyoxyethylene ether 1305, add In the reaction kettle, stir at...

Embodiment 3

[0047] 32.7 grams of methyl hydrogen silicone oil (hydrogen content 1.2%, viscosity 80cS), 88.4 grams of vinyl silicone oil (vinyl content 4%, viscosity 10000cS), 6.5 grams of fatty alcohol polyoxyethylene ether AEO-9, 10.5 grams of iso Construct decaol polyoxyethylene ether 1003, add it to the reaction kettle, stir at a stirring speed of 700 rpm for 20 minutes, mix well, add 40 grams of deionized water twice in a row, and use high-shear emulsification after each addition of water The machine was cut at a speed of 4000 rpm for 20 minutes, and finally 89.8 grams of deionized water was added, stirred for 10 minutes, and 0.2 grams of glacial acetic acid was added to adjust the pH value to 6 to obtain component A with a solid content of 40%.

[0048] 1 gram of chloroplatinic acid, 100 grams of vinyl silicone oil (vinyl content 1%, viscosity 2000cS), then add 5.3 grams of fatty alcohol polyoxyethylene ether AEO-9, 8.7 grams of isomeric decanol polyoxyethylene ether 1003, add In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com